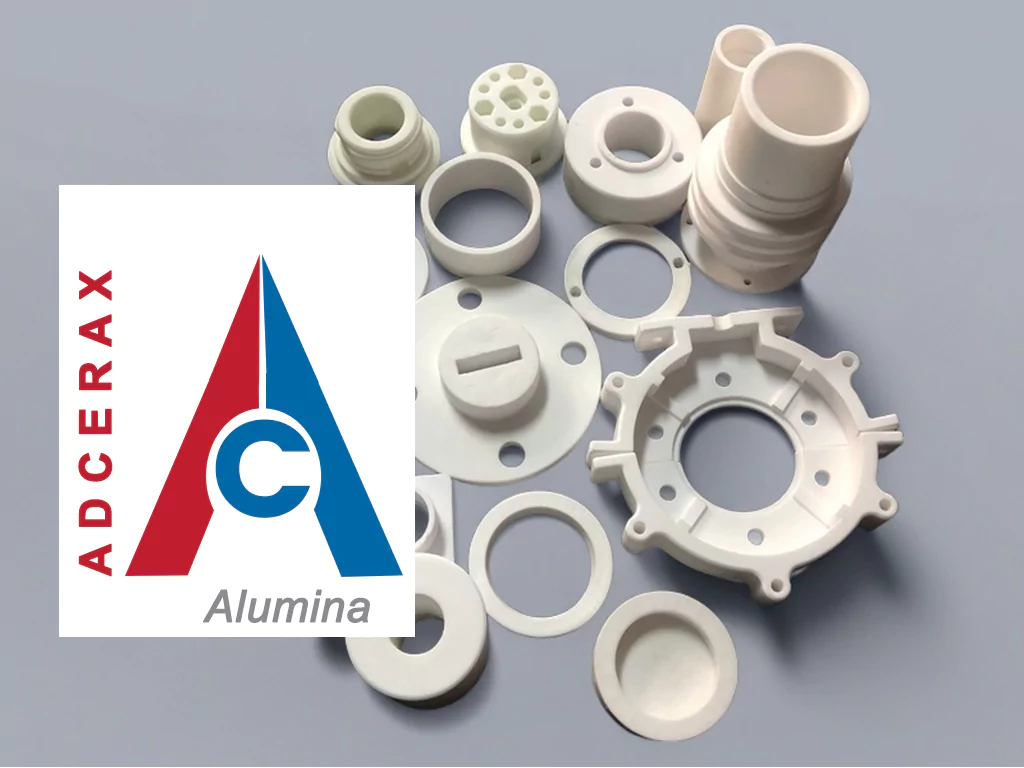

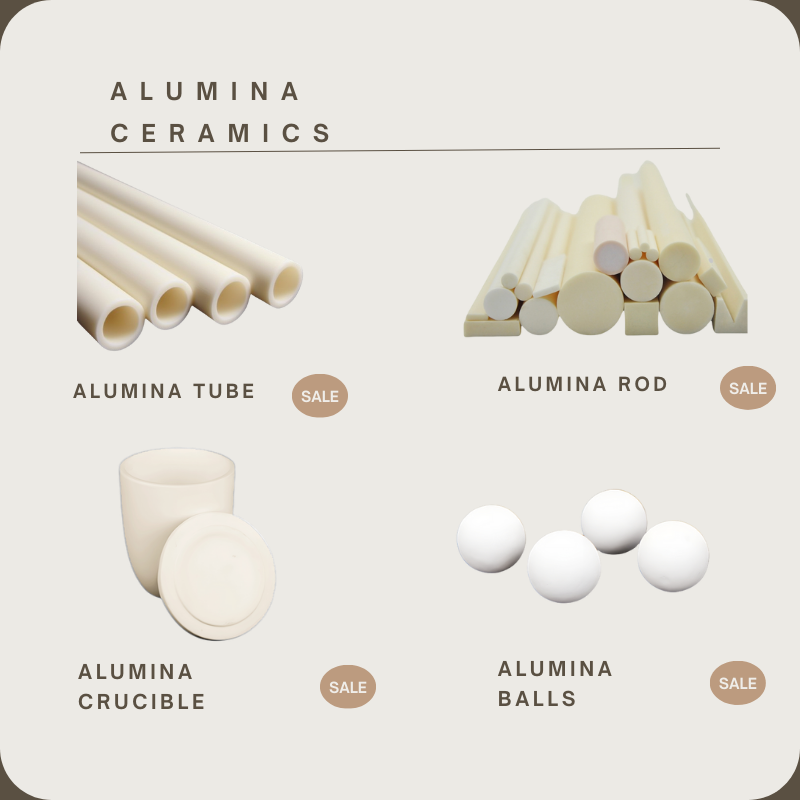

Engineered for critical high-temperature applications, our Ceramic Crucibles deliver exceptional purity, thermal shock resistance, and chemical inertness. Ensure reliable results and extended lifespan in your lab or industrial processes. Custom designs available.

Ceramic Crucible Material

Silicon Nitride Ceramic Crucible

Magnesia Ceramic Crucible

Aluminum Nitride Ceramic Crucible

Beryllium Oxide Ceramic Crucible

TGA Ceramic Crucible

DSC Ceramic Crucible

Ceramic Crucible Shape

Applications of Laboratory Ceramic Crucible

Our Ceramic Crucibles are trusted by professionals across various industries and research fields

FAQs About Industrial Ceramic Crucible

The best Ceramic Crucible material depends on your maximum operating temperature, the chemicals you'll be using, and your thermal shock requirements. For general high-temperature work up to 1750°C, an Alumina Ceramic Crucible is often excellent. For higher temperatures or very reactive materials, a Zirconia Ceramic Crucible might be more suitable. We recommend contacting our technical team to discuss your specific needs for your industrial or laboratory Ceramic Crucible.

A Laboratory Ceramic Crucible is incredibly versatile. Common uses include ashing samples, melting metals or glass, performing fusions, drying precipitates, general heating processes, and material synthesis. The inert nature and high-temperature resistance of a quality Ceramic Crucible make it indispensable for many analytical and preparatory tasks.

Absolutely! We specialize in providing Custom Ceramic Crucible solutions. If our standard range of Ceramic Crucibles doesn't fit your equipment or application, our technical team can work with you to design and manufacture a crucible ceramic to your precise dimensional and material specifications.

The lifespan of an Alumina Ceramic Crucible, or any Ceramic Crucible, depends heavily on the application, operating temperatures, heating/cooling rates, and the chemical environment it's exposed to. While a well-cared-for Alumina Ceramic Crucible can last for many cycles in less aggressive conditions, more extreme applications might reduce its lifespan. Using the correct crucible ceramic type for your process is key to maximizing its service life.

Choosing the right size and shape for your Ceramic Crucible involves considering the volume of material you need to process, the dimensions of your furnace or heating apparatus, and the nature of your application (e.g., melting might favor a different shape than ashing). Our product specifications list dimensions and capacities for each crucible ceramic, and our team is available to help you select the optimal Ceramic Crucible configuration.

Lead times for a custom Al2O3 Ceramic Boat can vary depending on the complexity of the design, quantity, and current production schedule. We strive for prompt turnaround times and will provide an estimated lead time upon reviewing your specific requirements for your Custom Ceramic Boat.

Yes, high-purity Alumina Ceramic Boat products are generally well-suited for use in vacuum furnace applications due to their low outgassing properties and high thermal stability. If you have specific vacuum level or outgassing requirements for your Ceramic Boat, please discuss them with our technical team.

Get a Precision Ceramics Quote Now !

Our team of experts is at your service to provide you with detailed product information and personalized quotation solutions.