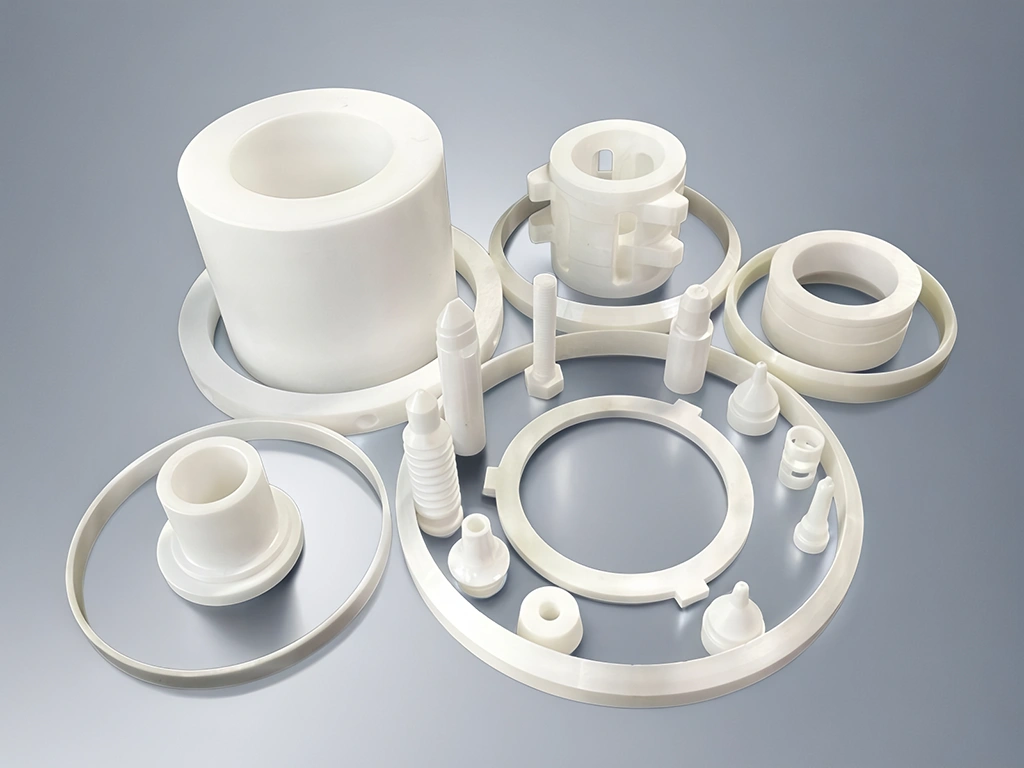

Explore how custom advanced ceramic solutions are transforming industries — from electronics to energy.

Zirconia Ceramic Max Temperature Limits Across 3Y-TZP YSZ MSZ CSZ

High-temperature assemblies fail when a “safe” number hides time, cycling, and damage. Escalating thermal loads amplify risk. A usable limit resolves continuous exposure, peaks, and

Zirconia Ceramic Thermal Conductivity Governing Factors

High-temperature systems frequently fail when heat transfer assumptions deviate from real material behavior, particularly once ceramics are expected to perform both thermal and structural functions

Zirconia Ceramic Chemical Resistance In Harsh Chemical Systems

High-performance systems often fail prematurely when material chemistry is misjudged under aggressive media. Misalignment between environment and material stability remains a dominant root cause across

Zirconia Ceramic Toughness Comparison Across 3Y-TZP YSZ MSZ CSZ

Unexpected fracture remains one of the most disruptive failure modes in oxide ceramic components, often occurring without visible warning and causing disproportionate system-level consequences. Zirconia-based

Zirconia Ceramic Density Ranges Across Y-TZP YSZ MSZ and CSZ Systems

High-performance zirconia components often fail to meet expectations because density assumptions are oversimplified or incorrectly generalized across stabilized systems. Zirconia ceramic density varies with stabilizer

Zirconia Ceramic Coefficient of Friction Under Real Operating Conditions

Unexpected frictional behavior remains one of the most frequent causes of premature ceramic component failure, especially when zirconia parts are transferred directly from material datasheets