Our silicon carbide seal rings are designed for high-performance industrial applications, offering exceptional durability, high-temperature resistance, and excellent wear resistance. Used for mechanical seals and harsh environments.

Silicon Carbide Seal Ring Advantages

- High Wear Resistance: runtime over 8,000 hours in standard pump rotation speeds (Ref: SKF Seal Application Guide)

- Dimensional Stability under Thermal Stress

- Chemically Stable against acids and alkalis (tested per ISO 9286 method)

- Maintain a low leakage rate (<0.08 g/h @ 6 bar) due to tight tolerance and polished mating face

- Clear material spec — sintered, not recrystallized, for higher density and lifespan

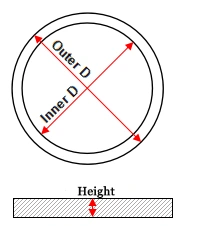

Specifications of Silicon Carbide Seal Ring

Type 1 Silicon Carbide Seal Ring

| Item | Outer D(mm) | Inner D(mm) | Height(mm) | Purity(%) |

| AT-SC-H001 | 10.0 | 5.0 | 2.1 | 99 |

| AT-SC-H002 | 10.0 | 6.0 | 3.5 | 99 |

| AT-SC-H003 | 11.0 | 6.0 | 3.0 | 99 |

| AT-SC-H004 | 11.5 | 4.0 | 3.5 | 99 |

| AT-SC-H005 | 11.9 | 6.0 | 4.5 | 99 |

| AT-SC-H006 | 12.0 | 6.0 | 4.0 | 99 |

| AT-SC-H007 | 12.9 | 8.5 | 3.0 | 99 |

| AT-SC-H008 | 14.5 | 8.5 | 3.5 | 99 |

| AT-SC-H009 | 14.5 | 8.0 | 4.0 | 99 |

| AT-SC-H010 | 14.5 | 9.0 | 3.5 | 99 |

| AT-SC-H011 | 14.5 | 9.0 | 4.0 | 99 |

| AT-SC-H012 | 14.5 | 10.0 | 4.0 | 99 |

| AT-SC-H013 | 14.5 | 8.5 | 3.5 | 99 |

| AT-SC-H014 | 18.0 | 12.0 | 4.0 | 99 |

| AT-SC-H015 | 20.0 | 6.0 | 4.0 | 99 |

| AT-SC-H016 | 22.3 | 15.2 | 11.0 | 99 |

| AT-SC-H017 | 25.0 | 16.0 | 6.0 | 99 |

| AT-SC-H018 | 25.0 | 18.0 | 6.0 | 99 |

| AT-SC-H019 | 26.0 | 14.0 | 4.0 | 99 |

| AT-SC-H020 | 26.0 | 20.0 | 5.0 | 99 |

| AT-SC-H021 | 28.0 | 12.0 | 4.0 | 99 |

| AT-SC-H022 | 28.0 | 22.0 | 7.0 | 99 |

| AT-SC-H023 | 28.0 | 21.0 | 4.0 | 99 |

| AT-SC-H024 | 31.0 | 18.0 | 10.0 | 99 |

| AT-SC-H025 | 32.0 | 20.0 | 3.0 | 99 |

| AT-SC-H026 | 32.8 | 22.6 | 11.0 | 99 |

| AT-SC-H027 | 34.0 | 23.0 | 4.5 | 99 |

| AT-SC-H028 | 34.5 | 28.0 | 5.0 | 99 |

| AT-SC-H029 | 36.0 | 20.0 | 10.0 | 99 |

| AT-SC-H030 | 36.0 | 26.0 | 14.0 | 99 |

| AT-SC-H031 | 37.0 | 30.0 | 7.0 | 99 |

Type 2 Silicon Carbide Seal Ring Stepped Ring

| Item | Outer Diameter (mm) | Inner Diameter (mm) | Thickness (mm) | Height (mm) | Purity |

| AT-THG-J10001 | 1-150 | 0.5-140 | 0.25-50 | 1-50 | 98.5 |

| AT-THG-J10002 | 25 | 15 | 5 | 15 | 98.5 |

| AT-THG-J10003 | 26 | 12 | 2 | 4 | 98.5 |

| AT-THG-J10004 | 31.60 | 20.49 | 5.56 | 11.11 | 98.5 |

| AT-THG-J10005 | 34.77 | 23.66 | 5.56 | 11.11 | 98.5 |

| AT-THG-J10006 | 37.95 | 26.95 | 5.50 | 12.70 | 98.5 |

| AT-THG-J10007 | 41.12 | 29.92 | 5.60 | 12.70 | 98.5 |

| AT-THG-J10008 | 47.47 | 33.30 | 7.09 | 12.70 | 98.5 |

| AT-THG-J10009 | 50.65 | 36.40 | 7.13 | 12.70 | 98.5 |

| AT-THG-J10010 | 53.82 | 39.57 | 7.13 | 12.70 | 98.5 |

| AT-THG-J10011 | 57.00 | 42.66 | 7.17 | 12.70 | 98.5 |

| AT-THG-J10012 | 60.17 | 46.03 | 7.07 | 12.70 | 98.5 |

| AT-THG-J10013 | 63.35 | 49.20 | 7.08 | 12.70 | 98.5 |

| AT-THG-J10014 | 66.52 | 52.38 | 7.07 | 12.70 | 98.5 |

| AT-THG-J10015 | 69.70 | 55.86 | 6.92 | 14.90 | 98.5 |

| AT-THG-J10016 | 72.87 | 59.03 | 6.92 | 14.90 | 98.5 |

| AT-THG-J10017 | 76.05 | 62.21 | 6.92 | 14.90 | 98.5 |

| AT-THG-J10018 | 79.22 | 65.38 | 6.92 | 15.88 | 98.5 |

| AT-THG-J10019 | 82.40 | 68.63 | 6.89 | 15.88 | 98.5 |

| AT-THG-J10020 | 85.57 | 71.81 | 6.88 | 15.88 | 98.5 |

| AT-THG-J10021 | 88.75 | 74.98 | 6.89 | 15.88 | 98.5 |

| AT-THG-J10022 | 91.92 | 78.16 | 6.88 | 15.88 | 98.5 |

| AT-THG-J10023 | 95.10 | 81.30 | 6.90 | 15.88 | 98.5 |

| AT-THG-J10024 | 98.27 | 84.51 | 6.88 | 15.88 | 98.5 |

| AT-THG-J10025 | 101.45 | 87.68 | 6.89 | 15.88 | 98.5 |

| AT-THG-J10026 | 104.62 | 90.86 | 6.88 | 17.46 | 98.5 |

| AT-THG-J10027 | 107.80 | 94.16 | 6.82 | 17.46 | 98.5 |

| AT-THG-J10028 | 114.15 | 97.33 | 8.41 | 17.46 | 98.5 |

| AT-THG-J10029 | 117.32 | 100.21 | 8.56 | 17.46 | 98.5 |

| AT-THG-J10030 | 120.20 | 103.68 | 8.26 | 17.46 | 98.5 |

Packing

Each silicon carbide ring is individually protected in EPE foam, with an inner vacuum-sealed bag and an outer carton.