Aluminum Nitride Ring is a precision-machined ceramic ring made from high-thermal-conductivity Aluminum Nitride (AlN). It functions as a thermal and electrical insulating spacer commonly used in power electronics, inverter modules, RF and microwave assemblies, vacuum chambers, high-power LED systems, and laser or photonics packages.

Aluminum Nitride Ring Advantages

-

High Thermal Conductivity in Ring Geometry

The Aluminum Nitride Ring structure allows efficient radial heat spreading around power modules, LED packages, and laser cavities. -

Electrical Insulation with High Dielectric Strength

Each AlN ceramic ring combines thermal conduction with strong electrical insulation, suitable for high-voltage and high-frequency assemblies. -

Tight Dimensional Tolerances for Precise Fit

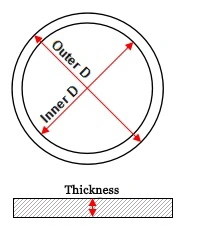

Precision grinding and machining enable outer and inner diameter tolerances down to ±0.05–0.1 mm, supporting accurate alignment and sealing in complex housings. -

High-Purity AlN for Stable Performance

High-purity Aluminum Nitride ceramic provides stable thermal properties, low outgassing, and consistent performance in vacuum and high-temperature environments. -

Flexible Thickness and Surface Finish Options

Aluminum Nitride Rings can be supplied in thin-wall or robust designs, with raw, lapped, or polished surfaces based on mounting and interface requirements.

AlN Ceramic Ring Properties

| Property Content | Unit | Unit | ALN-170 | ALN-200 | ALN-230 |

| Basic Properties | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

| Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

| Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

| Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

Aluminum Nitride Ring Specifications

| Item | Outer Diameter (mm) | Inner Diameter (mm) | Thickness (mm) |

| AT-ALN-H001 | 10.0 | 6.0 | 2.0 |

| AT-ALN-H002 | 15.0 | 10.0 | 2.5 |

| AT-ALN-H003 | 20.0 | 15.0 | 2.5 |

| AT-ALN-H004 | 25.0 | 21.0 | 2.0 |

| AT-ALN-H005 | 28.0 | 23.0 | 2.5 |

| AT-ALN-H006 | 31.0 | 26.0 | 2.5 |

| AT-ALN-H007 | 35.0 | 31.0 | 2.0 |

| AT-ALN-H008 | 48.0 | 40.0 | 4.0 |

| AT-ALN-H009 | 50.0 | 46.0 | 2.0 |

| AT-ALN-H010 | 50.0 | 45.0 | 2.5 |

| AT-ALN-H011 | 50.0 | 42.0 | 4.0 |

| AT-ALN-H012 | 50.0 | 40.0 | 5.0 |

| AT-ALN-H013 | 51.0 | 40.0 | 5.5 |

| AT-ALN-H014 | 55.5 | 39.5 | 8.0 |

| AT-ALN-H015 | 60.0 | 54.0 | 3.0 |

| AT-ALN-H016 | 65.0 | 45.0 | 10.0 |

| AT-ALN-H017 | 68.0 | 48.0 | 20.0 |

| AT-ALN-H018 | 90.0 | 86.0 | 2.0 |

| AT-ALN-H019 | 100.0 | 95.0 | 2.5 |

| AT-ALN-H020 | 10-450 | 6-410 | 2-20 |

Aluminum Nitride Ceramic Ring Packaging

- Each ring or small set of rings is first wrapped in clean cushioning material to avoid chipping of the edges.

- Rings are then placed in compartmented inner boxes or trays, separating individual parts to prevent mutual contact.