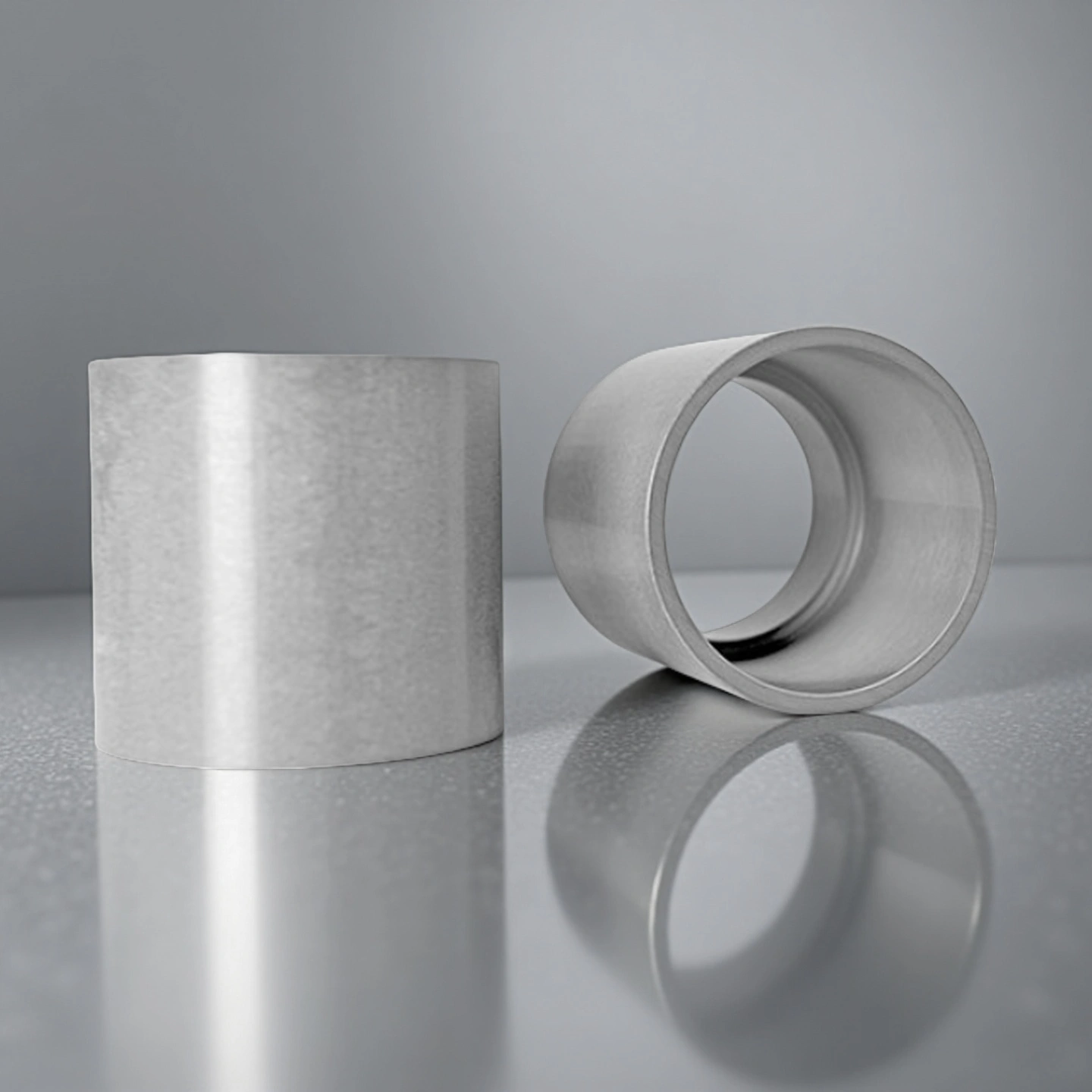

Silicon nitride insulation ring is a precision Si₃N₄ ceramic spacer used to electrically isolate mating parts while keeping tight dimensional control under temperature, load, and media exposure. It is commonly installed in mechanical seal chambers, pump/valve assemblies, vacuum flanges and feedthroughs, and motor or spindle end covers to block stray currents, stabilize sealing gaps, and reduce leak-related rework.

Silicon Nitride Insulation Ring Benefits

1. Electrical isolation under load

High dielectric strength (≥15–20 kV/mm per ASTM D149/IEC 60243) and stable volume resistivity (≥10¹² Ω·cm) maintain insulation in humid or chemically active environments. The silicon nitride insulation ring effectively prevents leakage currents and bearing pitting caused by stray voltages, ensuring long-term reliability for pumps and vacuum assemblies.

2. Dimensional stability

With a coefficient of thermal expansion of only 2.8–3.2 × 10⁻⁶/K (ASTM E228), the ring keeps alignment accuracy across wide temperature ranges. Excellent thermal shock resistance allows repeated heating and cooling cycles without warping or cracking, protecting fit tolerances in high-speed rotating systems.

3. Wear & corrosion resistance in seal chambers

The dense Si₃N₄ microstructure resists abrasion from slurry, vapour, and metallic contact surfaces. In field tests, wear loss is less than 0.05 mm after 1,000 hours of pump operation, reducing maintenance intervals and leakage incidents in chemical and water-treatment lines.

4. Machinable features for assembly

Precision grinding and CNC finishing enable IDs/ODs, grooves, and keyways to meet ±0.02–0.10 mm tolerance and flatness ≤0.05 mm. These controlled geometries improve first-time assembly rates by over 20 % compared with conventionally cast spacers, supporting consistent sealing performance in OEM production.

5. Surface options

Functional faces can be lapped or polished to Ra 0.4–0.8 µm, achieving uniform compression and stable sealing gaps. Optional selective polishing or raw-ground surfaces allow engineers to balance friction control and adhesive bonding needs depending on the sealing media and torque environment.

Si₃N₄ Insulation Ring Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Slicon Nitride Insulating Ring Specifications

| Si3N4 Insulation Ring | ||

| Item No. | Diameter(mm) | Height (mm) |

| AT-SIN-JY1001 | Customize | |

Silicon Nitride Isolation Ring Packaging

- Each silicon nitride ring is individually packed in anti-static foam trays and sealed in PE bags to prevent contamination. Bulk orders are shipped in reinforced wooden crates with shock-absorbing materials.

![]()