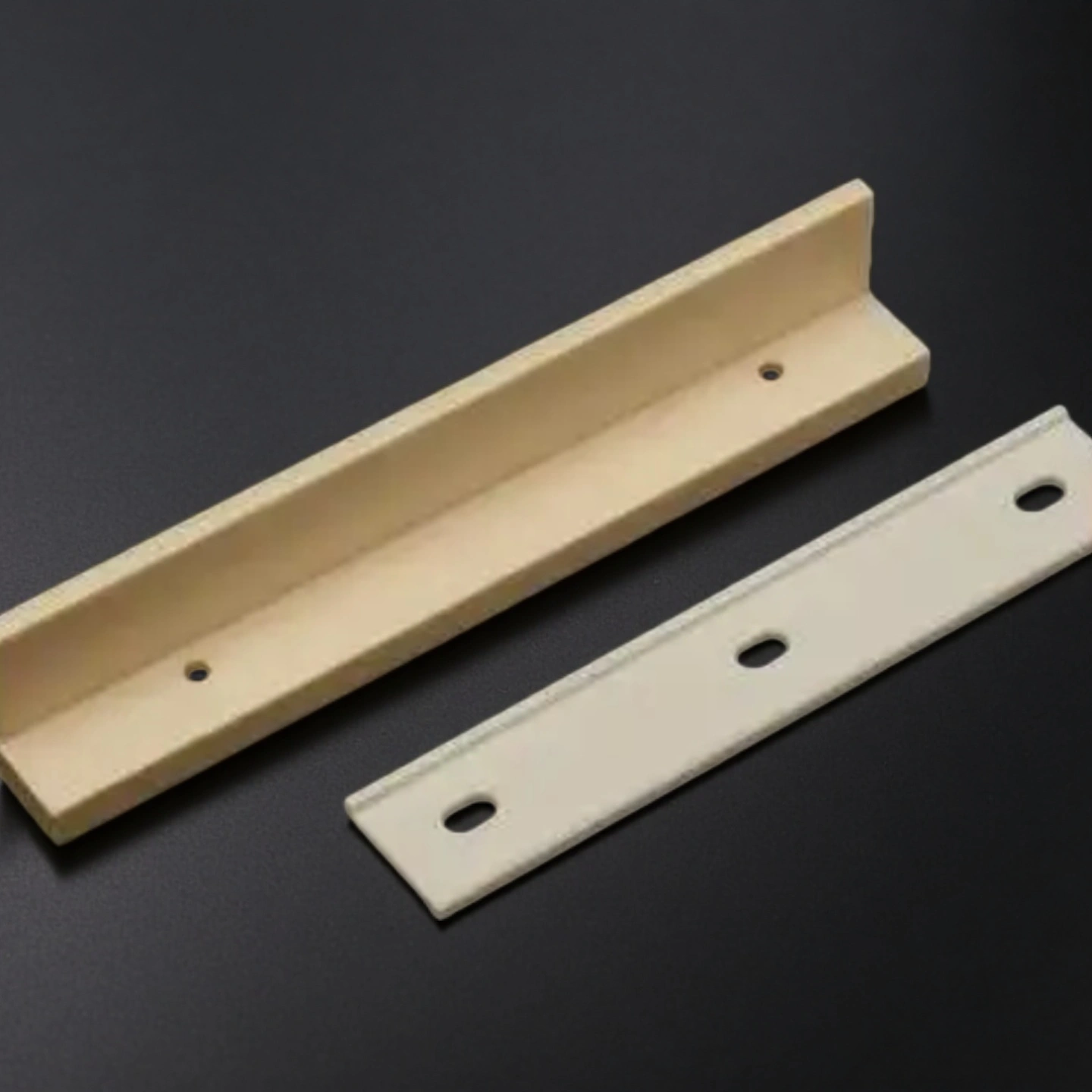

A High Purity Alumina Ceramic Guide Rail is a precision guide strip made from high-purity alumina (typically ≥99.5% Al₂O₃) that serves as a hard, wear-resistant and dimensionally stable reference surface for controlling motion direction and alignment in mechanical assemblies, such as vacuum coating equipment, automation fixtures, and other motion mechanisms where the guiding face and mounting datums must remain stable under repeated sliding and temperature variation.

High Purity Alumina Ceramic Guide Rail Benefits

-

Ground guiding faces for predictable contact behaviour, with grindable surfaces that can be specified to a defined roughness range (for example Ra 0.4–1.6 μm) so the motion path feels consistent and reduces stick–slip risk in sliding assemblies.

-

Datum-to-hole positional consistency for bolt-on installation, where the relationship between the guiding face, reference edges, and mounting holes is controlled to drawing, helping the rail drop into the mechanism without re-machining or slotting the base.

-

Edge and corner preparation options near functional zones, including controlled chamfers or radii around holes and at rail ends, lowering the chance of local chipping during handling, torqueing, or contact with mating parts while keeping the usable guiding width.

-

Wear-focused ceramic interface on the guiding side, using the high hardness of high purity alumina to slow down dimensional change of the contact face in repeated sliding, so the guide rail maintains its role as a stable reference surface over longer operating intervals.

-

Geometry stability over temperature variation in the assembly, as the rail’s thermal expansion and stiffness help preserve straightness and parallelism of the guiding face, supporting mechanisms where even small alignment drift would affect coating uniformity, positioning accuracy, or repeatability.

High Purity Alumina Ceramic Guide Rail Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

High Purity Alumina Ceramic Guide Rail Specifications

| High Purity Alumina Ceramic Guide Rail | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-HP-DG01 | Customize | |

High Purity Alumina Guide Rail Packaging

- Individual wrap to avoid ceramic-to-ceramic contact and edge impact during transit.

- Fixed-position foam slots so the guide rail cannot slide inside the carton.