Rectangular alumina crucible is a heat-resistant container made from high-purity Al₂O₃ (alumina), formed in a rectangular or square cross-section. It’s used for heating, calcining, melting, ashing, and holding solid or molten materials in laboratories and pilot-scale production where clean chemistry, dimensional stability, and high-temperature performance are required.

Benefits of Alumina Rectangular Crucible

- Tray-efficient geometry: Rectangular footprint packs densely on shelves and boats, enabling parallel processing without tipping or roll-over.

- Corner & wall control: Custom corner radii (R) and wall thickness preserve shape through rapid heat cycles and repeated handling.

- Lid & atmosphere options: Matching lids reduce volatilization and support controlled atmospheres during calcination or thermal analysis.

- Clean chemistry contact: Alumina contact surfaces limit contamination for oxides, salts, and many alloy tests where quartz or metals are unsuitable.

- Stable ml labelling: Capacity marked in ml simplifies recipe repeatability and batch documentation.

Alumina Crucibles Rectangular Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Rectangular Crucibles Specifications

Type 1- Rectangular Alumina Crucible

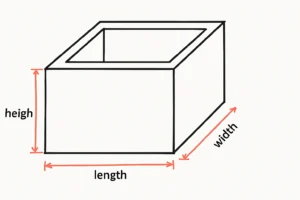

| Item NO. | Volume(ml) | length (mm) | width (mm) | height (mm) |

| TE-ASJ-93 | 0.9 | 45 | 8 | 6 |

| TE-AS-018 | 2.6 | 70 | 12 | 7 |

| TE-AS-005 | 2.8 | 50 | 10 | 10 |

| TE-ASJ-92 | 3 | 25 | 15 | 15 |

| TE-AS-006 | 3.6 | 50 | 12 | 10 |

| TE-AS-027 | 3.6 | 80 | 10 | 10 |

| TE-AS-001 | 4.2 | 27.5 | 23 | 10 |

| TE-AS-001-1 | 4.5 | 20 | 20 | 17 |

| TE-AS-005-9 | 4.5 | 20 | 20 | 17 |

| TE-ASJ-91 | 4.5 | 20 | 20 | 17 |

| TE-AS-036 | 5.8 | 100 | 10 | 10 |

| TE-AS-020 | 6.2 | 75 | 15 | 10 |

| TE-AS-002 | 6.7 | 30 | 20 | 16 |

| TE-AS-002-1 | 7.1 | 30 | 20 | 17 |

| TE-ASJ-90 | 7.1 | 30 | 20 | 17 |

| TE-AS-008 | 7.7 | 50 | 25 | 10 |

| TE-AS-005-2 | 8.5 | 42 | 22 | 13 |

| TE-ASJ-89 | 8.8 | 50 | 25 | 10 |

| TE-AS-005-1 | 9.2 | 45 | 22 | 13 |

| TE-AS-021 | 11.9 | 75 | 18 | 14 |

| TE-AS-035-6 | 13.2 | 98 | 18 | 12 |

| TE-AS-005-4 | 13.2 | 50 | 20 | 20 |

| TE-AS-005-5 | 13.2 | 50 | 28 | 14 |

| TE-AS-043-4 | 14 | 100 | 35 | 6 |

| TE-AS-016-6 | 14.7 | 61 | 47 | 8 |

| TE-ASJ-88 | 14.8 | 50 | 20 | 20 |

| TE-AS-016-2 | 15.3 | 60 | 25 | 15 |

| TE-AS-016-9 | 17.5 | 60 | 30 | 14 |

| TE-ASJ-86 | 18 | 60 | 30 | 15 |

| TE-ASJ-87 | 18 | 70 | 30 | 15 |

| TE-AS-017 | 18.5 | 65 | 23 | 18 |

| TE-AS-016-3 | 18.9 | 60 | 30 | 15 |

| TE-AS-029-2 | 19.4 | 85 | 34 | 10 |

| TE-AS-039 | 20 | 100 | 20 | 15 |

| TE-AS-022 | 20.4 | 75 | 20 | 20 |

| TE-AS-016-13 | 20.6 | 65 | 30 | 15 |

| TE-AS-005-8 | 20.8 | 30 | 30 | 30 |

| TE-AS-013 | 21.2 | 52 | 25 | 23 |

| TE-AS-019-5 | 22.3 | 70 | 30 | 15 |

| TE-ASJ-85 | 26 | 50 | 25 | 35 |

| TE-AS-052 | 26 | 110 | 24 | 17 |

| TE-AS-015 | 26.2 | 60 | 30 | 20 |

| TE-AS-016 | 26.2 | 60 | 40 | 15 |

| TE-AS-016-10 | 26.2 | 60 | 30 | 20 |

| TE-AS-039-1 | 26.2 | 100 | 25 | 15 |

| TE-AS-035-5 | 26.8 | 95 | 25 | 16 |

| TE-AS-065 | 27 | 150 | 20 | 20 |

| TE-AS-070 | 27 | 200 | 150 | 5 |

| TE-ASJ-84 | 28 | 100 | 20 | 20 |

| TE-ASJ-83 | 28.5 | 60 | 30 | 20 |

| TE-AS-051-10 | 29.2 | 100 | 20 | 21 |

| TE-AS-005-6 | 29.8 | 50 | 40 | 20 |

| TE-ASJ-81 | 31 | 110 | 24 | 17 |

| TE-AS-012 | 31.9 | 50 | 25 | 35 |

| TE-ASJ-80 | 32 | 100 | 50 | 10 |

| TE-ASJ-79 | 32.2 | 50 | 40 | 20 |

| TE-AS-061-2 | 33 | 120 | 30 | 15 |

| TE-AS-011-4 | 33 | 55 | 40 | 20 |

| TE-ASJ-78 | 34 | 55 | 40 | 20 |

| TE-AS-016-8 | 34 | 65 | 35 | 20 |

| TE-AS-051-1 | 35.3 | 100 | 50 | 10 |

| TE-ASJ-77 | 38 | 120 | 30 | 15 |

| TE-AS-054-3 | 39 | 113 | 30 | 18 |

| TE-AS-019-3 | 39.2 | 70 | 37 | 20 |

| TE-AS-003 | 39.4 | 35 | 35 | 40 |

| TE-AS-027-3 | 41 | 80 | 40 | 17 |

| TE-ASJ-76 | 43.9 | 60 | 30 | 30 |

| TE-ASJ-74 | 44 | 70 | 30 | 30 |

| TE-AS-041 | 44.9 | 100 | 30 | 20 |

| TE-AS-019-2 | 48 | 70 | 30 | 30 |

| TE-AS-005-7 | 48.7 | 50 | 50 | 25 |

| TE-ASJ-73 | 50 | 50 | 50 | 25 |

| TE-AS-004 | 52.7 | 40 | 40 | 40 |

| TE-AS-051 | 54.9 | 100 | 48 | 15 |

| TE-AS-038-4 | 57.4 | 100 | 30 | 25 |

| TE-ASJ-72 | 61 | 100 | 40 | 20 |

| TE-AS-024 | 65.5 | 75 | 75 | 15 |

| TE-AS-051-12 | 65.7 | 100 | 40 | 21 |

| TE-AS-051-2 | 69.9 | 100 | 30 | 30 |

| TE-ASJ-71 | 70 | 75 | 75 | 15 |

| TE-ASJ-70 | 70 | 100 | 30 | 30 |

| TE-AS-044 | 70.7 | 100 | 50 | 18 |

| TE-AS-070-26 | 72 | 250 | 35 | 15 |

| TE-AS-034-4 | 72.2 | 90 | 60 | 17 |

| TE-AS-070-31 | 75 | 400 | 20 | 20 |

| TE-ASJ-69 | 78 | 65 | 65 | 25 |

| TE-ASJ-68 | 84 | 65 | 65 | 30 |

| TE-AS-031 | 86.7 | 90 | 60 | 20 |

| TE-ASJ-67 | 91.7 | 90 | 60 | 20 |

| TE-AS-061-3 | 92 | 120 | 60 | 18 |

| TE-ASJ-63 | 100 | 65 | 65 | 35 |

| TE-ASJ-64 | 100 | 100 | 50 | 30 |

| TE-ASJ-65 | 100 | 120 | 60 | 20 |

| TE-AS-011 | 101.6 | 50 | 50 | 50 |

| TE-AS-016-11 | 104.2 | 65 | 65 | 30 |

| TE-AS-061-4 | 105 | 120 | 60 | 20 |

| TE-AS-016-7 | 108.5 | 62 | 38 | 57 |

| TE-AS-029-6 | 111 | 95 | 65 | 22 |

| TE-AS-062-5 | 117 | 120 | 60 | 22 |

| TE-AS-064-4 | 118 | 150 | 40 | 30 |

| TE-AS-019-1 | 122 | 70 | 70 | 30 |

| TE-AS-021-1 | 122.8 | 65 | 65 | 35 |

| TE-AS-051-4 | 123.6 | 100 | 50 | 30 |

| TE-AS-054-4 | 126 | 118 | 100 | 15 |

| TE-AS-062-7 | 129 | 120 | 100 | 15 |

| TE-ASJ-62 | 136 | 120 | 100 | 15 |

| TE-AS-029 | 138.3 | 85 | 65 | 30 |

| TE-AS-064-5 | 141 | 150 | 40 | 35 |

| TE-ASJ-61 | 141 | 150 | 40 | 30 |

| TE-AS-025 | 141.1 | 75 | 75 | 30 |

| TE-AS-019 | 143.7 | 70 | 70 | 35 |

| TE-AS-034 | 146.9 | 90 | 65 | 30 |

| TE-ASJ-60 | 150 | 70 | 70 | 30 |

| TE-AS-045 | 150.5 | 100 | 60 | 30 |

| TE-AS-070-32 | 152 | 800 | 20 | 20 |

| TE-AS-032 | 158.9 | 90 | 60 | 35 |

| TE-ASJ-59 | 160 | 100 | 100 | 20 |

| TE-AS-029-1 | 161.7 | 80 | 80 | 30 |

| TE-AS-023 | 163.6 | 75 | 52 | 50 |

| TE-AS-043-2 | 165.9 | 100 | 100 | 20 |

| TE-AS-035-4 | 166.2 | 98 | 72 | 28 |

| TE-ASJ-58 | 168 | 150 | 40 | 35 |

| TE-ASJ-57 | 173 | 90 | 60 | 40 |

| TE-AS-046 | 177.4 | 100 | 70 | 30 |

| TE-ASJ-55 | 180 | 80 | 80 | 40 |

| TE-ASJ-56 | 180 | 90 | 90 | 30 |

| TE-AS-034-3 | 183 | 90 | 60 | 40 |

| TE-AS-027-4 | 183.7 | 85 | 85 | 30 |

| TE-ASJ-51 | 197 | 90 | 60 | 45 |

| TE-ASJ-50 | 200 | 80 | 85 | 40 |

| TE-AS-067-5 | 204 | 175 | 55 | 30 |

| TE-ASJ-49 | 207 | 100 | 100 | 25 |

| TE-AS-034-1 | 207.1 | 90 | 90 | 30 |

| TE-AS-034-5 | 207.1 | 90 | 60 | 45 |

| TE-AS-051-5 | 212 | 100 | 100 | 25 |

| TE-AS-026 | 216.8 | 75 | 75 | 45 |

| TE-AS-026-2 | 219.5 | 80 | 80 | 40 |

| TE-ASJ-48 | 220 | 85 | 85 | 40 |

| TE-AS-062-2 | 221 | 120 | 120 | 20 |

| TE-ASJ-47 | 223 | 92 | 63 | 47 |

| TE-AS-061-5 | 228 | 120 | 60 | 40 |

| TE-AS-061-6 | 228 | 120 | 80 | 30 |

| TE-ASJ-46 | 233 | 120 | 60 | 40 |

| TE-AS-034-6 | 233.6 | 92 | 63 | 47 |

| TE-AS-026-3 | 233.9 | 80 | 85 | 40 |

| TE-ASJ-45 | 234 | 175 | 55 | 30 |

| TE-ASJ-44 | 243 | 120 | 80 | 30 |

| TE-AS-054-7 | 247 | 115 | 90 | 30 |

| TE-AS-030 | 249.3 | 85 | 85 | 40 |

| TE-AS-054-6 | 250 | 115 | 115 | 24 |

| TE-ASJ-43 | 255 | 115 | 90 | 30 |

| TE-ASJ-42 | 260 | 100 | 100 | 35 |

| TE-AS-054-2 | 270 | 115 | 65 | 45 |

| TE-ASJ-40 | 280 | 90 | 90 | 45 |

| TE-ASJ-41 | 280 | 120 | 80 | 40 |

| TE-AS-034-2 | 281 | 90 | 90 | 40 |

| TE-ASJ-39 | 284 | 115 | 65 | 45 |

| TE-AS-055 | 285 | 110 | 80 | 40 |

| TE-AS-057 | 291 | 120 | 75 | 40 |

| TE-ASJ-38 | 300 | 100 | 100 | 40 |

| TE-AS-048 | 304.1 | 100 | 100 | 35 |

| TE-AS-061 | 312 | 120 | 80 | 40 |

| TE-AS-029-4 | 318 | 90 | 90 | 45 |

| TE-AS-053-1 | 346 | 110 | 110 | 35 |

| TE-ASJ-37 | 350 | 115 | 115 | 35 |

| TE-AS-051-6 | 350.2 | 100 | 100 | 40 |

| TE-AS-062 | 351 | 120 | 120 | 30 |

| TE-AS-069-5 | 371 | 200 | 100 | 25 |

| TE-AS-061-1 | 380 | 115 | 115 | 35 |

| TE-AS-049 | 396.3 | 100 | 100 | 45 |

| TE-AS-070-27 | 406 | 178 | 85 | 35 |

| TE-ASJ-36 | 407 | 200 | 100 | 25 |

| TE-ASJ-35 | 424 | 100 | 100 | 50 |

| TE-ASJ-34 | 470 | 100 | 100 | 55 |

| TE-AS-064-3 | 488 | 145 | 145 | 30 |

| TE-AS-051-8 | 488.4 | 100 | 100 | 55 |

| TE-ASJ-33 | 516 | 100 | 100 | 60 |

| TE-ASJ-32 | 520 | 140 | 140 | 38 |

| TE-AS-064-7 | 524 | 150 | 150 | 30 |

| TE-AS-067-2 | 528 | 160 | 120 | 35 |

| TE-ASJ-31 | 530 | 145 | 145 | 30 |

| TE-AS-051-9 | 534.5 | 100 | 100 | 60 |

| TE-ASJ-29 | 550 | 120 | 120 | 50 |

| TE-ASJ-30 | 550 | 140 | 140 | 37 |

| TE-ASJ-28 | 554 | 150 | 150 | 30 |

| TE-ASJ-27 | 561 | 160 | 120 | 35 |

| TE-AS-064-1 | 575 | 140 | 140 | 35 |

| TE-AS-062-10 | 611 | 140 | 140 | 37 |

| TE-AS-062-9 | 611 | 120 | 120 | 50 |

| TE-AS-064-8 | 625 | 150 | 150 | 35 |

| TE-AS-064 | 664 | 140 | 140 | 40 |

| TE-ASJ-26 | 700 | 200 | 100 | 50 |

| TE-AS-062-3 | 718 | 120 | 100 | 70 |

| TE-ASJ-25 | 730 | 260 | 75 | 50 |

| TE-AS-064-14 | 732 | 150 | 120 | 50 |

| TE-AS-062-11 | 754 | 140 | 140 | 45 |

| TE-AS-070-15 | 777 | 260 | 75 | 50 |

| TE-AS-050-1 | 791 | 155 | 120 | 50 |

| TE-AS-050 | 811 | 100 | 100 | 90 |

| TE-AS-069-6 | 813 | 200 | 100 | 50 |

| TE-ASJ-23 | 850 | 150 | 150 | 50 |

| TE-AS-064-2 | 988 | 150 | 150 | 53 |

| TE-ASJ-22 | 996.1 | 160 | 160 | 45 |

| TE-ASJ-20 | 1000 | 150 | 110 | 80 |

| TE-ASJ-21 | 1000 | 160 | 160 | 50 |

| TE-AS-070-30 | 1025 | 360 | 120 | 30 |

| TE-AS-067-1 | 1063 | 160 | 160 | 50 |

| TE-AS-064-9 | 1101 | 150 | 110 | 80 |

| TE-AS-064-11 | 1129 | 150 | 150 | 60 |

| TE-ASJ-19 | 1150 | 305 | 90 | 57 |

| TE-ASJ-18 | 1175 | 150 | 150 | 60 |

| TE-AS-062-12 | 1203 | 140 | 140 | 70 |

| TE-AS-070-20 | 1227 | 305 | 90 | 57 |

| TE-ASJ-16 | 1273 | 120 | 120 | 100 |

| TE-AS-070-13 | 1324 | 250 | 160 | 40 |

| TE-AS-067-6 | 1361 | 180 | 180 | 50 |

| TE-AS-059-2 | 1371 | 130 | 120 | 100 |

| TE-ASJ-15 | 1430 | 160 | 120 | 85 |

| TE-ASJ-13 | 1500 | 180 | 180 | 60 |

| TE-ASJ-14 | 1500 | 200 | 200 | 50 |

| TE-AS-064-13 | 1532 | 150 | 150 | 80 |

| TE-AS-069-7 | 1634 | 200 | 120 | 80 |

| TE-ASJ-11 | 1650 | 240 | 170 | 50 |

| TE-AS-067-7 | 1657 | 180 | 180 | 60 |

| TE-ASJ-10 | 1680 | 200 | 120 | 80 |

| TE-AS-069-9 | 1696 | 200 | 200 | 50 |

| TE-AS-070-7 | 1729 | 240 | 170 | 50 |

| TE-AS-067 | 1756 | 160 | 160 | 80 |

| TE-AS-043-3 | 1824.8 | 100 | 400 | 50 |

| TE-AS-064-6 | 1907 | 150 | 100 | 150 |

| TE-AS-070-21 | 2079 | 340 | 220 | 35 |

| TE-AS-067-4 | 2327 | 160 | 140 | 120 |

| TE-AS-070-24 | 2473 | 224 | 224 | 57 |

| TE-ASJ-7 | 2500 | 250 | 155 | 80 |

| TE-ASJ-6 | 2600 | 200 | 200 | 80 |

| TE-AS-070-9 | 2612 | 250 | 150 | 80 |

| TE-AS-070-11 | 2704 | 250 | 155 | 80 |

| TE-AS-070-2 | 2802 | 200 | 200 | 80 |

| TE-ASJ-5 | 3000 | 300 | 180 | 70 |

| TE-ASJ-4 | 3200 | 220 | 220 | 80 |

| TE-AS-070-17 | 3205 | 300 | 180 | 70 |

| TE-ASJ-3 | 3300 | 200 | 200 | 100 |

| TE-AS-070-29 | 3362 | 300 | 210 | 61 |

| TE-AS-070-6 | 3416 | 220 | 220 | 80 |

| TE-AS-070-16 | 3451 | 300 | 150 | 90 |

| TE-AS-070-3 | 3539 | 200 | 200 | 100 |

| TE-ASJ-2 | 3566 | 300 | 150 | 90 |

| TE-AS-070-18 | 4133 | 300 | 200 | 80 |

| TE-AS-070-8 | 4451 | 250 | 250 | 80 |

| TE-AS-069-11 | 5000 | 250 | 250 | 100 |

| TE-AS-069-10 | 5100 | 340 | 220 | 35 |

| TE-AS-069-91 | 5250 | 250 | 200 | 125 |

| TE-AS-069-8 | 5344 | 200 | 150 | 200 |

| TE-AS-070-25-1 | 5400 | 200 | 150 | 200 |

| TE-AS-070-12 | 5622 | 250 | 200 | 125 |

| TE-AS-070-14 | 5622 | 250 | 250 | 100 |

| TE-AS-070-22-1 | 7465 | 330 | 330 | 80 |

| TE-AS-070-23-1 | 15760 | 330 | 330 | 160 |

| Item NO. | Volume(ml) | length (mm) | width (mm) | height (mm) | |

| TE-AS-182 | 1 | 45 | 8 | 6 | with cover |

| TE-AS-149 | 1.3 | 45 | 8 | 6 | with cover |

| TE-AS-183 | 3 | 25 | 15 | 15 | with cover |

| TE-AS-148 | 4 | 25 | 15 | 15 | with cover |

| TE-AS-171 | 4 | 20 | 20 | 17 | with cover |

| TE-AS-125 | 7 | 30 | 20 | 17 | with cover |

| TE-AS-172 | 9 | 50 | 25 | 10 | with cover |

| TE-AS-116-1 | 15 | 50 | 20 | 20 | with cover |

| TE-AS-117 | 15.7 | 50 | 20 | 21 | with cover |

| TE-AS-126 | 17 | 50 | 20 | 23 | with cover |

| TE-AS-128 | 21 | 60 | 30 | 15 | with cover |

| TE-AS-184 | 26 | 50 | 25 | 35 | with cover |

| TE-AS-115 | 28 | 60 | 30 | 20 | with cover |

| TE-AS-116 | 29 | 60 | 30 | 21 | with cover |

| TE-AS-129 | 31 | 60 | 30 | 23 | with cover |

| TE-AS-109-3 | 34 | 100 | 20 | 23 | with cover |

| TE-AS-112 | 31 | 100 | 20 | 20 | with cover |

| TE-AS-137 | 32 | 100 | 20 | 21 | with cover |

| TE-AS-127 | 32 | 50 | 40 | 20 | with cover |

| TE-AS-150 | 35 | 50 | 25 | 35 | with cover |

| TE-AS-185 | 40 | 50 | 50 | 25 | with cover |

| TE-AS-130 | 44 | 60 | 30 | 30 | with cover |

| TE-AS-111 | 48 | 100 | 30 | 20 | with cover |

| TE-AS-110 | 66 | 100 | 40 | 20 | with cover |

| TE-AS-186 | 68 | 65 | 65 | 25 | with cover |

| TE-AS-131 | 70 | 75 | 75 | 15 | with cover |

| TE-AS-173 | 75 | 100 | 30 | 30 | with cover |

| TE-AS-187 | 84 | 65 | 65 | 30 | with cover |

| TE-AS-115 | 92 | 90 | 60 | 20 | with cover |

| TE-AS-188 | 110 | 70 | 70 | 30 | with cover |

| TE-AS-142 | 110 | 120 | 60 | 18 | with cover |

| TE-AS-189 | 115 | 65 | 65 | 35 | with cover |

| TE-AS-108-2 | 123 | 120 | 60 | 20 | with cover |

| TE-AS-140 | 130 | 100 | 50 | 30 | with cover |

| TE-AS-190 | 150 | 100 | 100 | 25 | with cover |

| TE-AS-112 | 154 | 90 | 65 | 30 | with cover |

| TE-AS-191 | 170 | 90 | 90 | 30 | with cover |

| TE-AS-114 | 191 | 90 | 60 | 40 | with cover |

| TE-AS-135 | 216 | 90 | 60 | 45 | with cover |

| TE-AS-132 | 228 | 80 | 80 | 40 | with cover |

| TE-AS-108-1 | 257 | 120 | 60 | 40 | with cover |

| TE-AS-145 | 257 | 120 | 80 | 30 | with cover |

| TE-AS-192 | 260 | 100 | 100 | 35 | with cover |

| TE-AS-136 | 329 | 90 | 90 | 45 | with cover |

| TE-AS-193 | 330 | 115 | 115 | 35 | with cover |

| TE-AS-146 | 347 | 120 | 80 | 40 | with cover |

| TE-AS-141 | 362 | 100 | 100 | 40 | with cover |

| TE-AS-194 | 370 | 200 | 100 | 25 | with cover |

| TE-AS-196 | 510 | 120 | 120 | 50 | with cover |

| TE-AS-197 | 520 | 140 | 140 | 38 | with cover |

| TE-AS-174 | 550 | 100 | 100 | 60 | with cover |

| TE-AS-162 | 616 | 150 | 150 | 30 | with cover |

| TE-AS-198 | 750 | 150 | 150 | 50 | with cover |

| TE-AS-199 | 800 | 200 | 100 | 50 | with cover |

| TE-AS-147 | 1072 | 160 | 160 | 45 | with cover |

| TE-AS-176 | 1264 | 150 | 150 | 60 | with cover |

| TE-AS-175 | 1286 | 140 | 140 | 70 | with cover |

| TE-AS-200 | 1460 | 180 | 180 | 60 | with cover |

| TE-AS-201 | 1480 | 200 | 200 | 50 | with cover |

| TE-AS-177 | 1696 | 150 | 150 | 80 | with cover |

| TE-AS-202 | 2400 | 250 | 155 | 80 | with cover |

| TE-AS-203 | 2600 | 200 | 200 | 80 | with cover |

| TE-AS-204 | 2830 | 300 | 180 | 70 | with cover |

| TE-AS-178 | 3823 | 200 | 200 | 100 | with cover |

| TE-AS-179 | 6009 | 250 | 250 | 100 | with cover |

| TE-AS-180 | 8394 | 330 | 330 | 80 | with cover |

| TE-AS-181 | 16948 | 330 | 330 | 160 | with cover |

Alumina Rectangular Crucible Packaging

- Protective packing: each crucible wrapped and nested with foam; inner carton + outer export box to minimize chipping.

- Optional lids: flat or recessed type, matching fit.