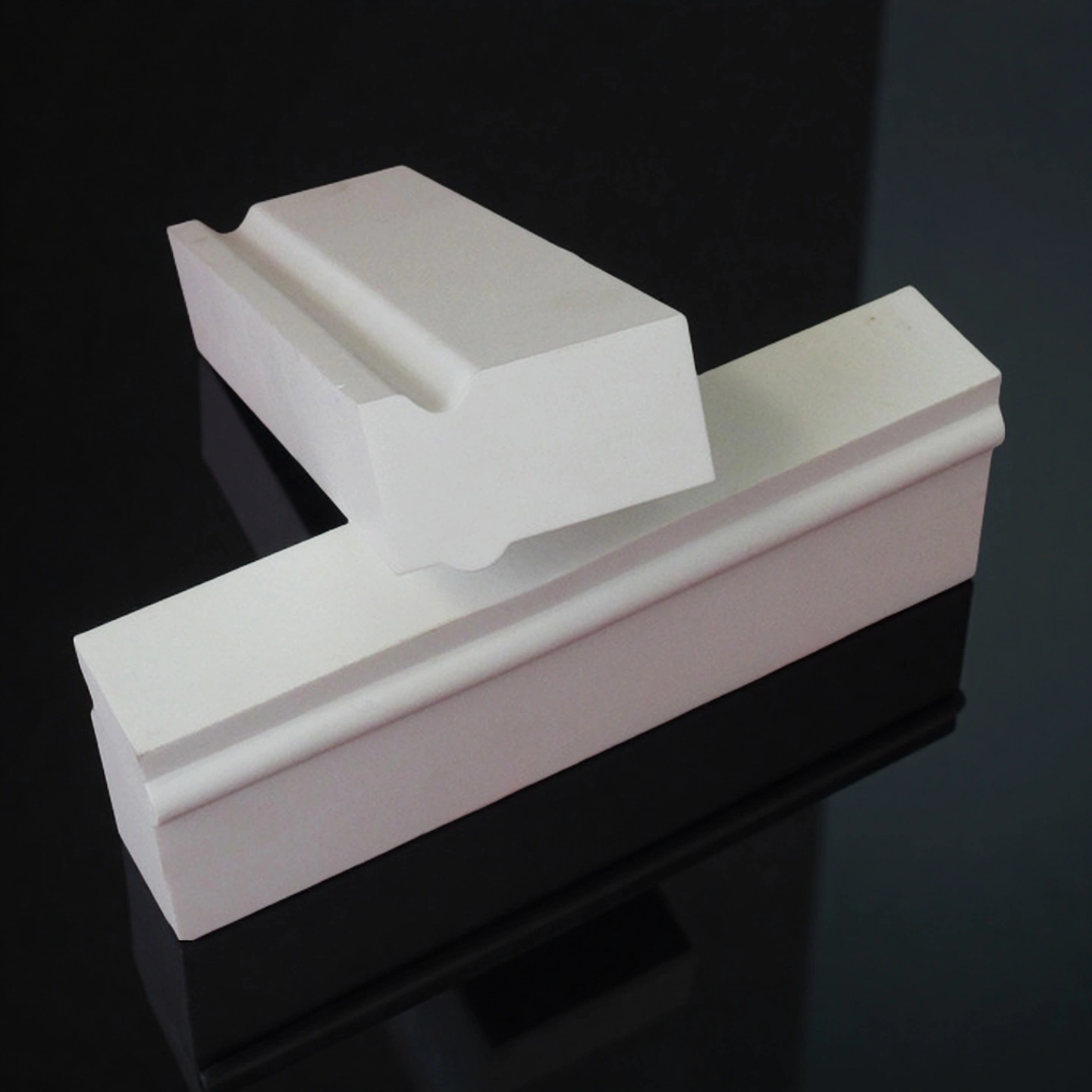

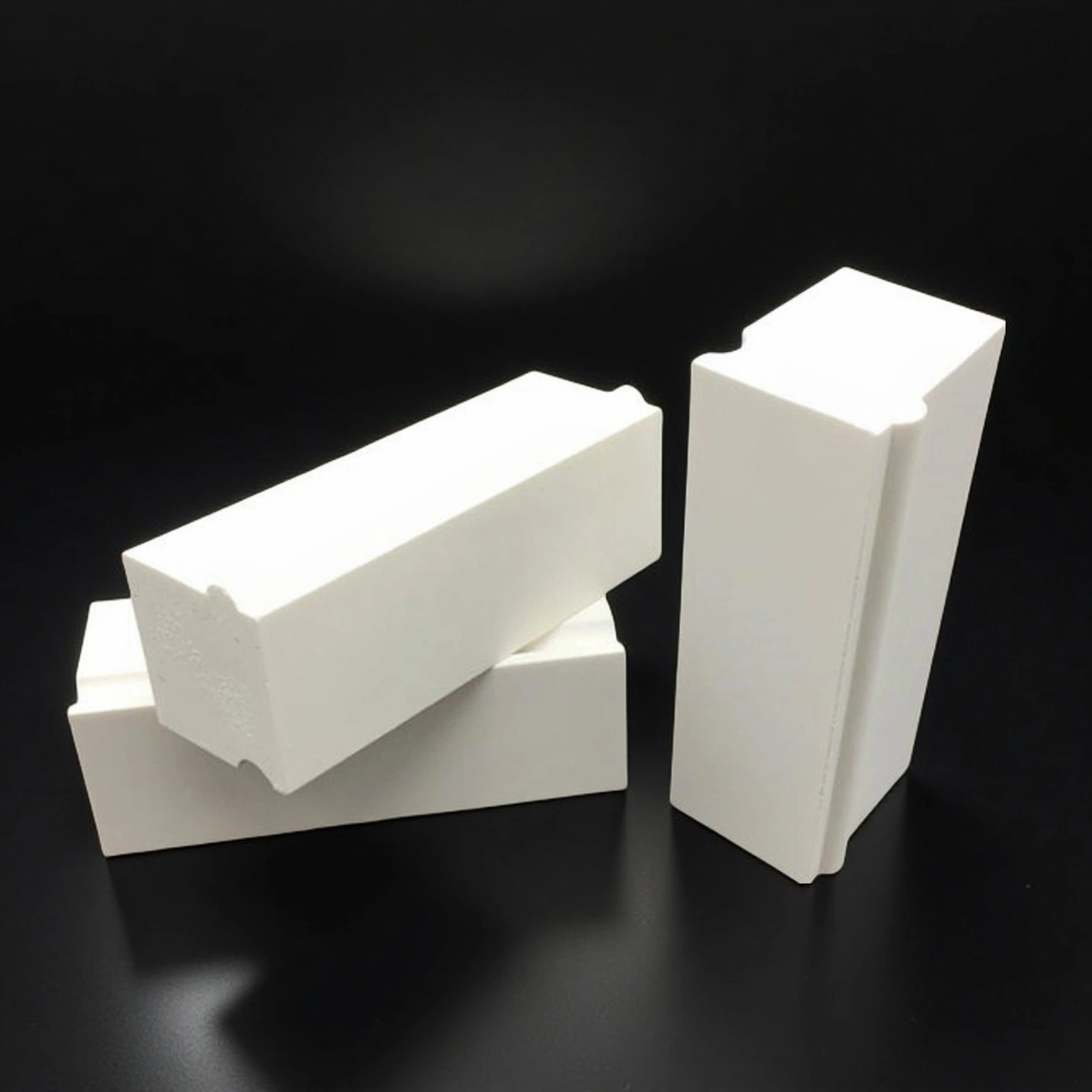

Zirconia Toughened Alumina Bricks (ZTA) are high-performance ceramic wear bricks made from an alumina (Al₂O₃) matrix reinforced with finely dispersed zirconia (ZrO₂) particles. This composite structure significantly increases fracture toughness and impact resistance compared with standard alumina bricks, while retaining high hardness and abrasion resistance.

Zirconia Toughened Alumina Brick Benefits

-

Balanced wear and impact performance

ZTA bricks combine high hardness and higher fracture toughness than standard alumina, improving resistance to both sliding abrasion and repeated impact in ore transfer and grinding equipment. -

Extended service life compared with 92% alumina

Case studies of ZTA ceramic liners in flotation and slurry handling have reported up to about 2.8 times longer service life than 92% alumina liners under similar duty, reducing liner change frequency and shutdown count. -

Stable performance at elevated temperature

ZTA materials can operate up to around 1500 °C in dry conditions, maintaining mechanical strength and wear resistance in high-temperature zones such as some sinter and clinker transfer points. -

Designed for heavy industrial duty

ZTA bricks are suited to severe conditions where steel plates may wear in months and standard alumina may crack, including high-speed impact of ore particles and dense slurry transport in mining and steel plants. -

Compatible with common installation systems

Bricks can be drilled, slotted or bonded to steel, rubber or composite backings, supporting glue-on, bolt-on or mechanically fastened lining systems used by many mining and bulk handling operators.

ZTA Ceramic Brick Properties

| Property | Unit | Pyrolytic Boron Nitride | Hot Pressed Boron Nitride |

| Purity | 99.99% | 99.50% | |

| Density | g/cm3 | 2.15-2.19 | 1.96-2 |

| Hardness | HV0.5 | 651 | 62 |

| Volume resistivity | Ohm*cm | 2*1014 | 1.2*1014 |

| Dielectric strength | kV/mm | 55 | 76 |

| Maximum working temperature | ℃ | 1000 (air), 2300 (vacuum) | 900 (air), 1850 (vacuum) |

| Bending strength | MPa | 173 (A direction) | 310 |

| Thermal conductivity | W/m*K | 60 (A direction) | 55 |

| Tensile strength | MPa | 112 (A direction) | 110 |

| Thermal expansion coefficient | /℃ | 6*10-7 | 1.8*10-6 |

| Compressive strength | MPa | 154 (A direction) | 120 |

ZTA Brick Specifications

| ZTA Brick | |||

| Item No. | Height(mm) | Upper Width/Lower Width(mm) | Length(mm) |

| AT-YHG-CZ1001 | 15 | 45/50 | 150 |

| AT-YHG-CZ1002 | 25 | 45/50 | 150 |

| AT-YHG-CZ1003 | 35 | 45/50 | 150 |

| AT-YHG-CZ1004 | 40 | 45/50 | 150 |

| AT-YHG-CZ1005 | 50 | 45/50 | 150 |

| AT-YHG-CZ1006 | 60 | 45/50 | 150 |

| AT-YHG-CZ1007 | 70 | 45/50 | 150 |

| AT-YHG-CZ1008 | 90 | 45/50 | 150 |

| AT-YHG-CZ1009 | 100 | 45/50 | 150 |

| AT-YHG-CZ1010 | 15 | 50 | 75 |

| AT-YHG-CZ1011 | 25 | 50 | 75 |

| AT-YHG-CZ1012 | 35 | 50 | 75 |

| AT-YHG-CZ1013 | 40 | 50 | 75 |

| AT-YHG-CZ1014 | 50 | 50 | 75 |

| AT-YHG-CZ1015 | 60 | 50 | 75 |

| AT-YHG-CZ1016 | 70 | 50 | 75 |

| AT-YHG-CZ1017 | 90 | 50 | 75 |

| AT-YHG-CZ1018 | 100 | 50 | 75 |

| AT-YHG-CZ1019 | 15 | 45/50 | 75 |

| AT-YHG-CZ1020 | 25 | 45/50 | 75 |

| AT-YHG-CZ1021 | 35 | 45/50 | 75 |

| AT-YHG-CZ1022 | 40 | 45/50 | 75 |

| AT-YHG-CZ1023 | 50 | 45/50 | 75 |

| AT-YHG-CZ1024 | 60 | 45/50 | 75 |

| AT-YHG-CZ1025 | 70 | 45/50 | 75 |

| AT-YHG-CZ1026 | 90 | 45/50 | 75 |

| AT-YHG-CZ1027 | 100 | 45/50 | 75 |

| AT-YHG-CZ1028 | 15 | 25 | 150 |

| AT-YHG-CZ1029 | 25 | 25 | 150 |

| AT-YHG-CZ1030 | 35 | 25 | 150 |

| AT-YHG-CZ1031 | 40 | 25 | 150 |

| AT-YHG-CZ1032 | 50 | 25 | 150 |

| AT-YHG-CZ1033 | 60 | 25 | 150 |

| AT-YHG-CZ1034 | 70 | 25 | 150 |

| AT-YHG-CZ1035 | 90 | 25 | 150 |

| AT-YHG-CZ1036 | 100 | 25 | 150 |

| AT-YHG-CZ1037 | 15 | 22.5/25 | 150 |

| AT-YHG-CZ1038 | 25 | 22.5/25 | 150 |

| AT-YHG-CZ1039 | 35 | 22.5/25 | 150 |

| AT-YHG-CZ1040 | 40 | 22.5/25 | 150 |

| AT-YHG-CZ1041 | 50 | 22.5/25 | 150 |

| AT-YHG-CZ1042 | 60 | 22.5/25 | 150 |

| AT-YHG-CZ1043 | 70 | 22.5/25 | 150 |

| AT-YHG-CZ1044 | 90 | 22.5/25 | 150 |

| AT-YHG-CZ1045 | 100 | 22.5/25 | 150 |

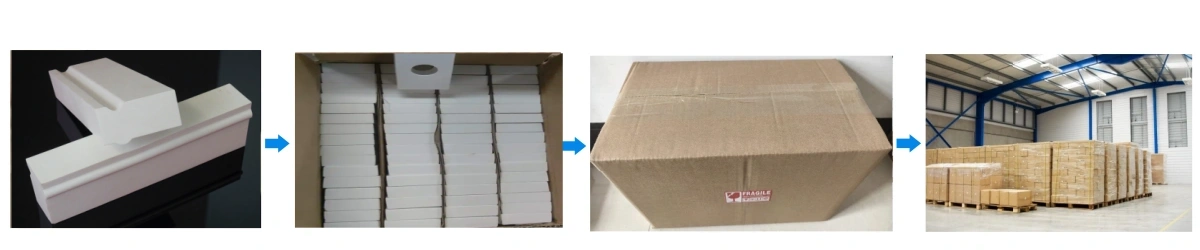

Zirconia Toughened Alumina Ceramic Brick Packing

- Bricks are packed in layered rows inside reinforced cartons or wooden crates, with separators to avoid ceramic-to-ceramic impact during transport.