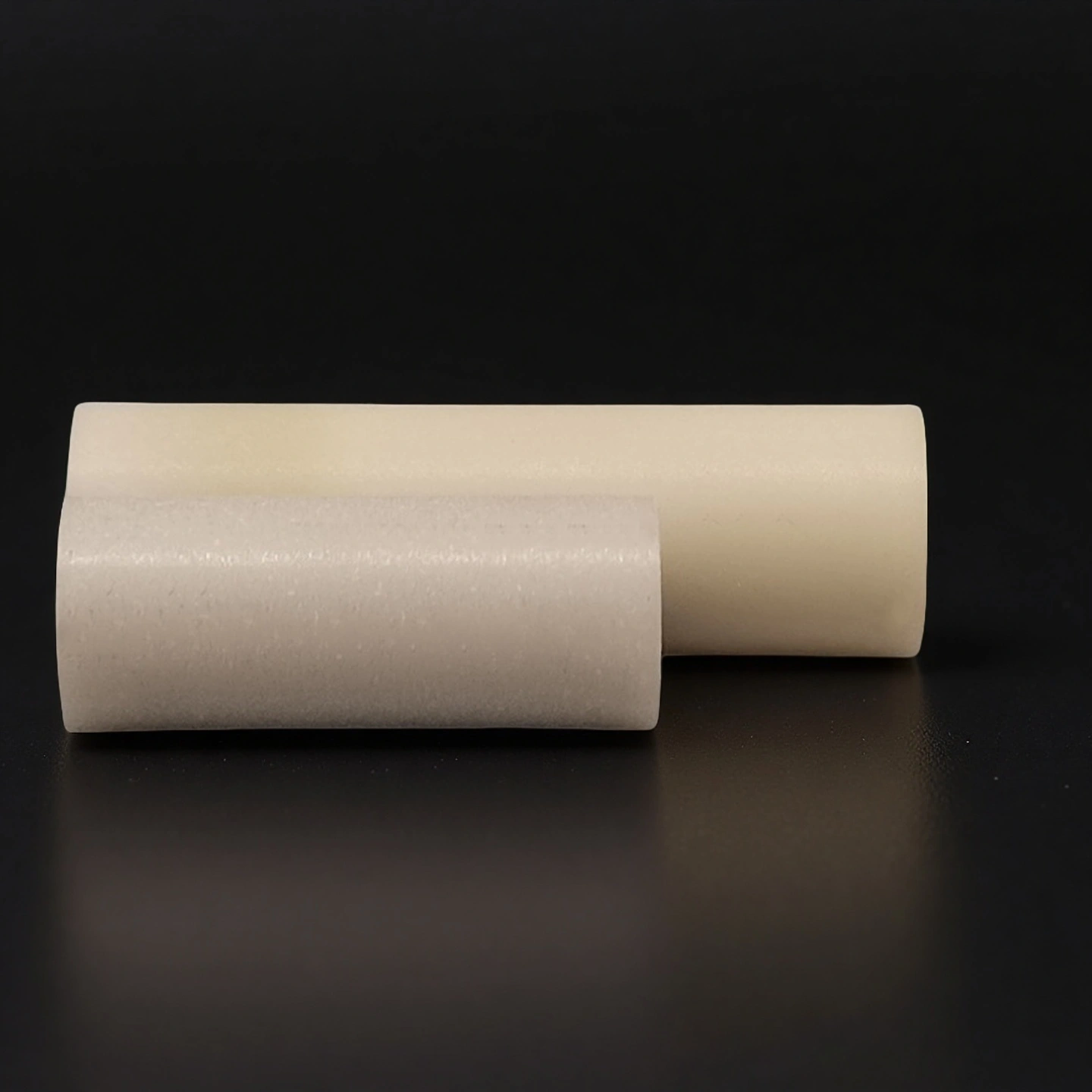

An aluminum nitride rod is a dense ceramic rod made from aluminum nitride (AlN), designed to combine high thermal conductivity with high electrical insulation in a single component. Compared with common alumina rods, an aluminum nitride rod can transfer heat much more efficiently while still acting as a dielectric insulator, so it is often used close to power devices, heaters and electronic components that generate significant heat.

Aluminium Nitride Rod Benefits

-

High heat dissipation along the rod length

Aluminum nitride ceramic rod combines high thermal conductivity with electrical insulation, suitable for carrying heat away from power devices while keeping circuits insulated. -

Dimensional precision for engineered assemblies

Machined AlN rod can be produced with tight diameter and length tolerances, which helps minimize assembly misalignment in semiconductor tools and fixtures. -

Thermal expansion closer to Si and SiC devices

The coefficient of thermal expansion of aluminum nitride rod is closer to semiconductor materials than alumina, helping reduce thermal stress in bonded or clamped structures. -

High strength and fracture resistance in slim geometries

A dense AlN ceramic rod can maintain mechanical strength even in smaller diameters, which supports slender support rods and probe shafts in high-temperature or vacuum conditions. -

Stable insulation at elevated temperatures

Aluminum nitride ceramic rods keep high electrical resistivity at operating temperatures used in many power electronics and furnace environments, which supports safe insulation design.

Aluminum Nitride Ceramic Rod Properties

| Property Content | Unit | Unit | ALN-170 | ALN-200 | ALN-230 |

| Basic Properties | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

| Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

| Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

| Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

Aluminum Nitride Rod Specifications

| Aluminium Nitride Rod | ||

| Item No. | Diameter(mm) | Length (mm) |

| AT-ALN-B1001 | 0.38 | 120 |

| AT-ALN-B1002 | 0.5 | 120 |

| AT-ALN-B1003 | 0.635 | 120 |

| AT-ALN-B1004 | 1.0 | 120 |

| AT-ALN-B1005 | 1.5 | 120 |

| AT-ALN-B1006 | 2.0 | 120 |

| AT-ALN-B1007 | 4.0 | 50 |

| AT-ALN-B1008 | 5.0 | 50 |

| AT-ALN-B1009 | 7.5 | 100 |

| AT-ALN-B1010 | 7.5 | 50 |

| AT-ALN-B1011 | 16.0 | 51 |

| AT-ALN-B1012 | 18.5 | 60 |

| AT-ALN-B1013 | 22.0 | 50 |

| AT-ALN-B1014 | 22.0 | 67 |

| AT-ALN-B1015 | 28.0 | 120 |

| AT-ALN-B1016 | 31.0 | 120 |

| AT-ALN-B1017 | 32.0 | 120 |

| AT-ALN-B1018 | 34.0 | 120 |

| AT-ALN-B1019 | 45.0 | 120 |

| AT-ALN-B1020 | 47.0 | 120 |

AlN Rod Packaging

- Each aluminum nitride ceramic rod is individually wrapped or separated with soft spacers to avoid hard contact between rods.