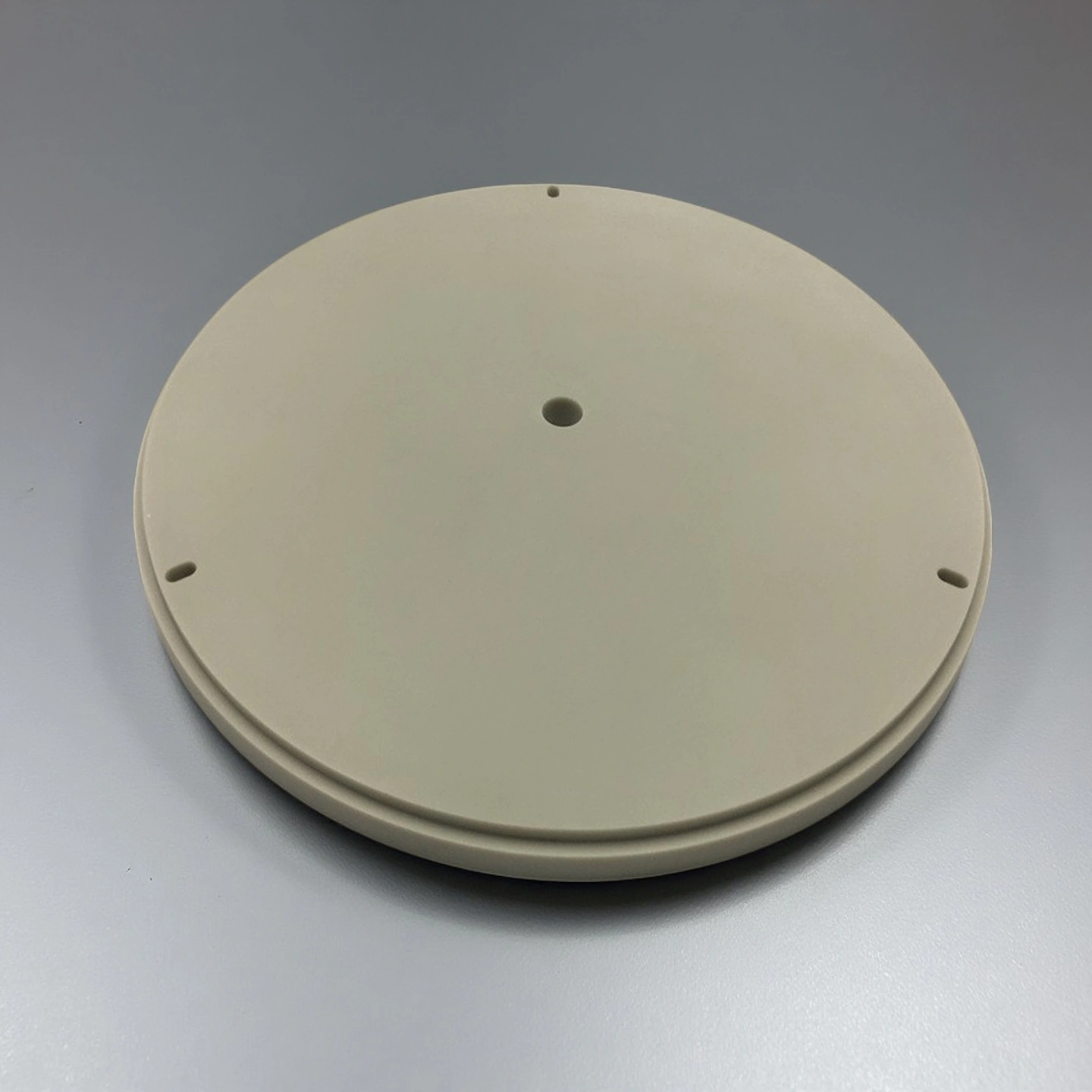

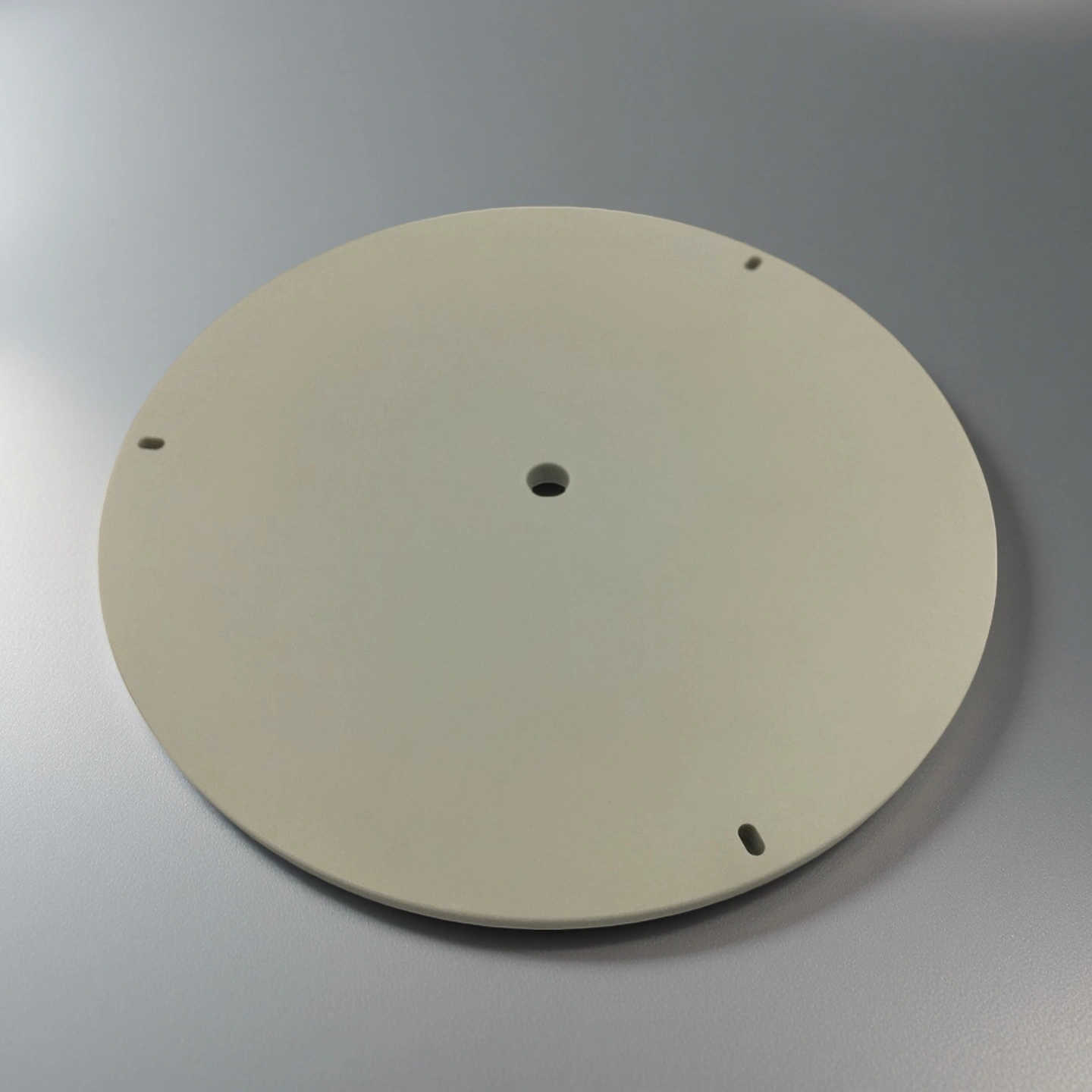

An aluminum nitride sheet is a flat, plate-like ceramic component made from aluminum nitride (AlN) that is used as a thermally conductive, electrically insulating base in electronic and optoelectronic assemblies.

Aluminum Nitride Sheet Benefits

-

High heat dissipation for compact designs

Aluminum nitride ceramic sheet provides thermal conductivity in the 140–180 W/m·K range, enabling higher power density and lower junction temperature compared with alumina substrates. -

Electrical insulation with silicon-matched expansion

The AlN ceramic sheet combines high dielectric strength with a coefficient of thermal expansion close to silicon, supporting reliable chip attachment and thermal cycling in demanding applications. -

Stable properties at elevated temperature

Aluminum nitride sheet maintains mechanical strength, insulation resistance and thermal performance at operating temperatures commonly required in power electronics and LED drivers. -

Precision machining for complex layouts

ADCERAX can supply aluminum nitride sheets with precision grinding, drilled holes, slots and complex outer profiles to follow customer module layouts. -

Suitable for multiple high-value industries

The same AlN ceramic sheet platform can be used across power conversion, LED and UV curing, RF modules and optical communication packages, allowing standardization of materials across product lines.

Aluminium Nitride Ceramic Sheet Properties

| Property Content | Unit | Unit | ALN-170 | ALN-200 | ALN-230 |

| Basic Properties | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

| Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

| Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

| Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

AlN Sheet Specifications

Type 1: AlN Sheet Round

| AlN Sheet Round | ||||

| Item No. | Diameter (mm) | Thickness(mm) | Thermal conductivity(W/m.k) | Purity(%) |

| AT-AIN-YP0001 | 100 | 2 | 170-230 | 92-99.5 |

| AT-AIN-YP0002 | 100 | 2.5 | 170-230 | 92-99.5 |

| AT-AIN-YP0003 | 100 | 4 | 170-230 | 92-99.5 |

| AT-AIN-YP0004 | 100 | 5 | 170-230 | 92-99.5 |

| AT-AIN-YP0005 | 100 | 5.5 | 170-230 | 92-99.5 |

| AT-AIN-YP0006 | 100 | 8 | 170-230 | 92-99.5 |

| AT-AIN-YP0007 | 100 | 10 | 170-230 | 92-99.5 |

| AT-AIN-YP0008 | 100 | 20 | 170-230 | 92-99.5 |

| AT-AIN-YP0009 | 200 | 2 | 170-230 | 92-99.5 |

| AT-AIN-YP0010 | 200 | 2.5 | 170-230 | 92-99.5 |

| AT-AIN-YP0011 | 200 | 4 | 170-230 | 92-99.5 |

| AT-AIN-YP0012 | 200 | 5 | 170-230 | 92-99.5 |

| AT-AIN-YP0013 | 200 | 5.5 | 170-230 | 92-99.5 |

| AT-AIN-YP0014 | 200 | 8 | 170-230 | 92-99.5 |

| AT-AIN-YP0015 | 200 | 10 | 170-230 | 92-99.5 |

| AT-AIN-YP0016 | 200 | 20 | 170-230 | 92-99.5 |

| AT-AIN-YP0017 | 300 | 2 | 170-230 | 92-99.5 |

| AT-AIN-YP0018 | 300 | 2.5 | 170-230 | 92-99.5 |

| AT-AIN-YP0019 | 300 | 4 | 170-230 | 92-99.5 |

| AT-AIN-YP0020 | 300 | 5 | 170-230 | 92-99.5 |

| AT-AIN-YP0021 | 300 | 5.5 | 170-230 | 92-99.5 |

| AT-AIN-YP0022 | 300 | 8 | 170-230 | 92-99.5 |

| AT-AIN-YP0023 | 300 | 10 | 170-230 | 92-99.5 |

| AT-AIN-YP0024 | 300 | 20 | 170-230 | 92-99.5 |

| AT-AIN-YP0025 | 350 | 4 | 170-230 | 92-99.5 |

| AT-AIN-YP0026 | 350 | 5 | 170-230 | 92-99.5 |

| AT-AIN-YP0027 | 350 | 5.5 | 170-230 | 92-99.5 |

| AT-AIN-YP0028 | 350 | 8 | 170-230 | 92-99.5 |

| AT-AIN-YP0029 | 350 | 10 | 170-230 | 92-99.5 |

| AT-AIN-YP0030 | 350 | 20 | 170-230 | 92-99.5 |

| AT-AIN-YP0031 | 400 | 5 | 170-230 | 92-99.5 |

| AT-AIN-YP0032 | 400 | 5.5 | 170-230 | 92-99.5 |

| AT-AIN-YP0033 | 400 | 8 | 170-230 | 92-99.5 |

| AT-AIN-YP0034 | 400 | 10 | 170-230 | 92-99.5 |

| AT-AIN-YP0035 | 400 | 20 | 170-230 | 92-99.5 |

| AT-AIN-YP0036 | 450 | 5 | 170-230 | 92-99.5 |

| AT-AIN-YP0037 | 450 | 5.5 | 170-230 | 92-99.5 |

| AT-AIN-YP0038 | 450 | 8 | 170-230 | 92-99.5 |

| AT-AIN-YP0039 | 450 | 10 | 170-230 | 92-99.5 |

| AT-AIN-YP0040 | 450 | 20 | 170-230 | 92-99.5 |

Type 2: AlN Sheet Square

| AlN Sheet Square | |||||

| Item No. | Length (mm) | Width (mm) | Thickness (mm) | Thermal conductivity | Purity(%) |

| AT-AIN-FP0001 | 10 | 10 | 2-5 | 170-230 | 92-99.5 |

| AT-AIN-FP0002 | 20 | 20 | 2-5 | 170-230 | 92-99.5 |

| AT-AIN-FP0003 | 50 | 50 | 2-5 | 170-230 | 92-99.5 |

| AT-AIN-FP0004 | 65 | 65 | 2-5 | 170-230 | 92-99.5 |

| AT-AIN-FP0005 | 80 | 80 | 2-5 | 170-230 | 92-99.5 |

| AT-AIN-FP0006 | 70 | 20 | 2-5 | 170-230 | 92-99.5 |

| AT-AIN-FP0007 | 100 | 50 | 4-10 | 170-230 | 92-99.5 |

| AT-AIN-FP0008 | 130 | 85 | 4-10 | 170-230 | 92-99.5 |

| AT-AIN-FP0009 | 170 | 110 | 10-20 | 170-230 | 92-99.5 |

| AT-AIN-FP0010 | 200 | 130 | 10-20 | 170-230 | 92-99.5 |

| AT-AIN-FP0011 | 260 | 200 | 10-20 | 170-230 | 92-99.5 |

| AT-AIN-FP0012 | 320 | 180 | 10-20 | 170-230 | 92-99.5 |

| AT-AIN-FP0013 | 340 | 240 | 10-20 | 170-230 | 92-99.5 |

| AT-AIN-FP0014 | 350 | 130 | 10-20 | 170-230 | 92-99.5 |

| AT-AIN-FP0015 | 360 | 170 | 10-20 | 170-230 | 92-99.5 |

Aluminum Nitride Ceramic Sheet Packing

- Each aluminum nitride sheet is separated in rigid plastic trays or cavity blister packs to prevent edge chipping and surface contact.