DSC Alumina Pans are frequently adopted after inconsistent DSC curves appear during pharmaceutical testing. Consequently, repeated scans of the same API often diverge, not because of material variability, but due to uncontrolled method execution variables.

In pharmaceutical DSC analysis, inconsistent results create immediate uncertainty in solid-state interpretation. However, these inconsistencies are rarely caused by the DSC instrument itself. Instead, uncontrolled variables across experimental stages progressively erode data reproducibility.

This article defines controlled DSC execution using DSC Alumina Pans for pharmaceutical testing. It covers sample preparation, pan loading, lid configuration, purge atmosphere, heating programs, artifact prevention, and quantitative data acceptance criteria required for reproducible thermal analysis.

Before individual experimental stages are examined, it is essential to establish where this controlled execution framework applies and where it does not. Accordingly, the following section defines the method scope and decision boundaries that govern all subsequent SOP parameters.

Before detailing execution-level controls, the applicability and limits of alumina-based DSC methods must be defined. Consequently, this section establishes the decision boundary that determines when the following procedures are technically valid.

Method Scope and Decision Boundary for Pharmaceutical DSC with Alumina Pans

In pharmaceutical DSC workflows, DSC Alumina Pans redefine the thermal boundary of measurement. Therefore, method applicability must be clearly delimited before execution-level parameters are applied.

-

Pharmaceutical DSC applications suitable for alumina pan execution

DSC Alumina Pans are appropriate for pharmaceutical analyses that prioritize chemical inertness and thermal stability over maximum signal sharpness. Typical use cases include polymorphism screening, glass transition determination, melting behavior evaluation, excipient compatibility studies, and preliminary thermal stability assessments. In these applications, onset temperature repeatability can be controlled within ±0.5 °C and enthalpy variation across replicate runs can be maintained below ±4% when execution parameters are properly managed.

Accordingly, alumina pan methods align best with decision-making tasks that require interpretable and reproducible thermal trends. -

Conditions indicating the need for method re-optimization

When aluminum-based DSC parameters are transferred directly to alumina pans, systematic deviations are frequently observed. In practice, peak broadening of 10–20%, muted glass transition steps, or onset shifts exceeding ±1.0 °C signal that heat-flow equilibration has changed. These effects arise from differences in thermal conductivity and contact behavior rather than changes in sample properties.

Therefore, alumina pan adoption should be treated as a method change event that triggers controlled parameter reassessment. -

Quantitative boundaries defining valid alumina-based DSC execution

For pharmaceutical DSC using alumina pans, acceptance boundaries must be defined to separate valid data from method-induced artifacts. Baseline drift during a single run should remain below 3%, while peak width changes after method transfer should not exceed 15%. Exceeding these thresholds indicates that execution variables, not sample behavior, dominate the DSC signal.

Within these limits, subsequent SOP steps can be applied with confidence to achieve controlled DSC execution.

These scope and boundary definitions establish the foundation for all downstream sample preparation and execution controls discussed in the following sections.

Sample Preparation SOP for Pharmaceutical DSC Using Alumina Pans

In pharmaceutical DSC analysis, sample preparation governs heat-flow uniformity before any instrument parameter takes effect. Therefore, preparation variables must be stabilized first, because DSC Alumina Pans amplify preparation-related differences rather than masking them. Moreover, consistent preparation directly determines whether subsequent DSC curves are reproducible across repeated runs.

Powder Packing vs Loose Fill

Powder packing defines how thermal energy enters and exits the sample bed. Consequently, the decision between light packing and loose fill should be based on volatility and decomposition behavior rather than habit.

In practical pharmaceutical DSC work, lightly packed crystalline APIs often show improved onset consistency compared to loosely filled powders. For example, during routine polymorph screening1, analysts frequently observe onset temperature variability below ±0.5 °C when light packing is applied, whereas loose fill can exceed ±1.2 °C due to uneven heat transfer. However, excessive compaction creates diffusion barriers, and over-packed samples have repeatedly produced delayed endothermic onsets by 2–4 °C in stability studies.

Accordingly, reproducible execution relies on controlled light packing rather than forceful compression or completely loose filling.

Sample Mass Control at the Milligram Level

Sample mass directly influences heat-flow magnitude and equilibration time in DSC Alumina Pans. Therefore, mass control must be treated as a quantitative variable rather than an approximate target.

In laboratory practice, pharmaceutical DSC methods typically operate within a narrow mg-level mass window. When relative mass deviation is held within ±10%, enthalpy variation across replicate runs generally remains below ±4%. By contrast, deviations exceeding this threshold have been associated with enthalpy scatter greater than ±8% and visibly distorted peak symmetry during routine compatibility testing.

As a result, analytical weighing verification is required before pan loading rather than relying on visual estimation.

Spread Thickness and Contact Geometry

Geometric distribution inside the alumina pan determines lateral and vertical heat-flow paths. Consequently, uniform spreading is essential to minimize internal temperature gradients during heating.

During method development, evenly spread samples covering approximately 70–80% of the pan base consistently yield sharper and more symmetric peaks. In contrast, centrally piled or domed samples frequently generate shoulder peaks or delayed maxima that vary between runs. Such artifacts are often misinterpreted as polymorphic complexity when, in fact, they originate from uneven contact geometry.

Therefore, visual inspection of spread thickness should be a mandatory preparation checkpoint before DSC execution.

Summary of Sample Preparation Control Targets

| Parameter | Controlled Target |

|---|---|

| Packing approach | Light packing or loose fill based on volatility |

| Onset temperature repeatability (°C) | ≤ ±0.5 |

| Sample mass deviation (%) | ≤ ±10 |

| Enthalpy variation across runs (%) | ≤ ±4 |

| Pan base coverage (%) | ≥ 70 |

| Peak delay due to over-packing (°C) | ≤ 2 |

By stabilizing packing, mass, and geometry at this stage, DSC Alumina Pans provide a consistent thermal interface that allows downstream loading, lid selection, and heating programs to operate without compensating for upstream variability.

Pan Loading and Handling SOP to Prevent Boundary Errors

After sample preparation is stabilized, pan loading becomes the next critical control point in pharmaceutical DSC execution. Therefore, even minor handling inconsistencies can propagate into measurable heat-flow artifacts when DSC Alumina Pans are used. Moreover, alumina pans make boundary errors more visible, which allows prevention but penalizes careless execution.

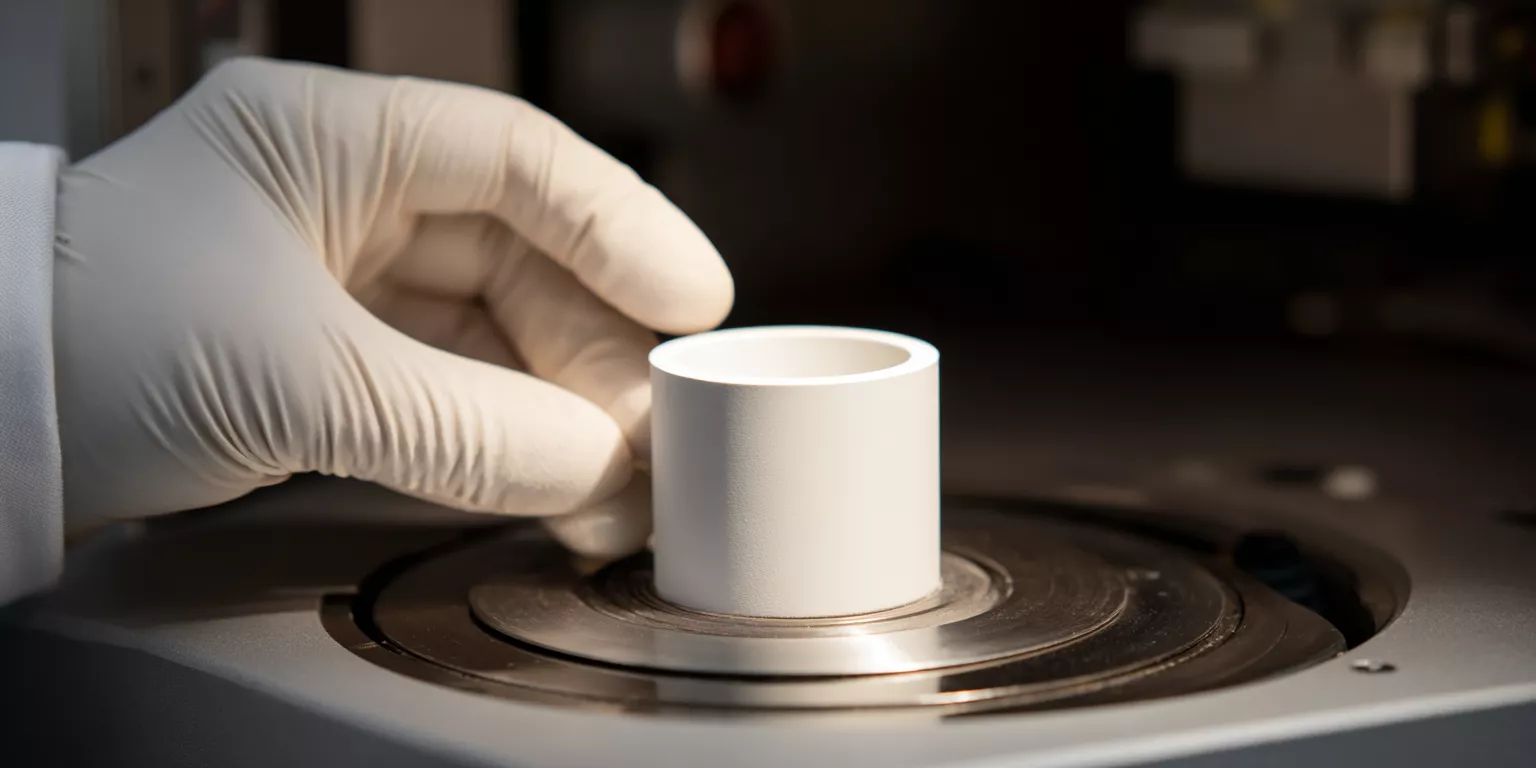

Centering, Seating, and Sensor Contact Verification

Correct centering and seating define the physical boundary between the sample pan and the DSC sensor. Consequently, loading accuracy determines whether heat transfer remains symmetrical during heating.

In routine laboratory operation, analysts often notice that slightly off-center alumina pans produce subtle baseline curvature or delayed onsets without obvious visual warning. For example, during repeat Tg measurements, a pan that rocks imperceptibly on the sensor has been shown to increase onset variability from ±0.5 °C to nearly ±1.3 °C. These deviations originate from uneven thermal contact rather than instrument instability.

Therefore, centering and seating checks should be treated as a quantitative verification step rather than a visual assumption.

Practical Verification of Stable Pan–Sensor Contact

Stable contact must be confirmed before every pharmaceutical DSC run. Accordingly, gentle lateral probing with ceramic tweezers can reveal rocking or tilt that is not visible at rest.

In practice, laboratories that implement a simple contact verification step report improved baseline consistency across replicate runs. Empty-pan baseline scans typically remain within ±3% drift when seating is correct, whereas unstable contact often produces baseline shifts exceeding ±6%. Such differences are repeatable and diagnostic, not random noise.

As a result, contact verification serves as an early indicator of boundary integrity before valuable samples are consumed.

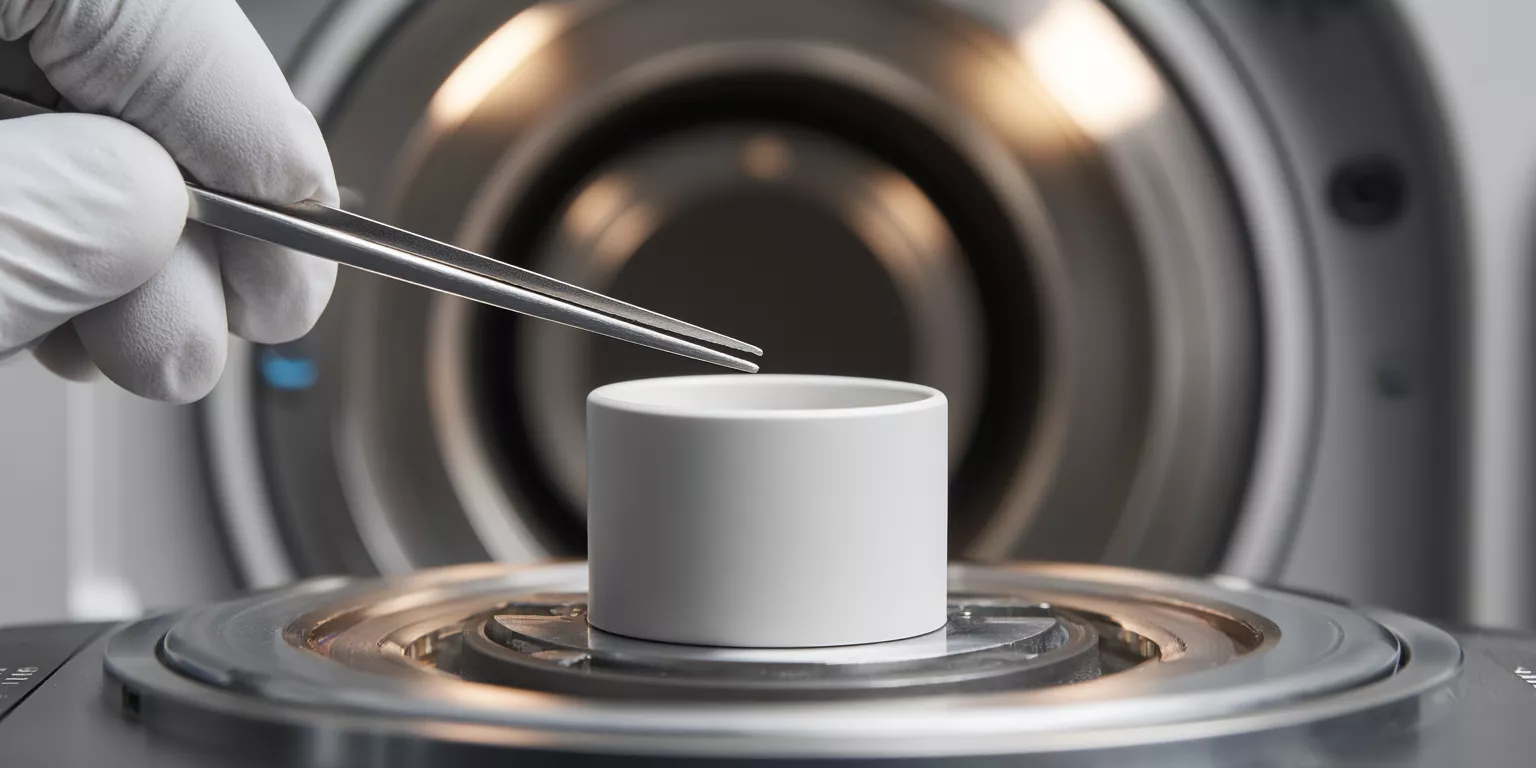

Contamination Control During Pan Loading

Pharmaceutical DSC testing is highly sensitive to cross-contamination introduced during handling. Therefore, loading procedures must isolate each sample from prior residues and environmental exposure.

Experienced analysts consistently report that trace contamination from tweezers or work surfaces can introduce low-level exothermic artifacts between 200 °C and 350 °C. In compatibility studies, such artifacts have been mistaken for weak interaction signals until controlled handling eliminated them. Dedicated ceramic tweezers and defined loading order significantly reduce this risk.

Accordingly, contamination control during loading is a data integrity requirement rather than a housekeeping preference.

Handling Sequence and Workspace Discipline

The sequence of handling actions influences contamination probability and mechanical stability. Consequently, a consistent loading workflow reduces variability between operators.

In high-throughput pharmaceutical laboratories, standardized handling order has reduced repeat-run enthalpy variation by approximately 20% compared to ad hoc workflows. Simple practices such as staging pans on clean ceramic trays and minimizing air exposure time before loading have measurable impact. These improvements are often observed only after method reproducibility is formally reviewed.

Thus, disciplined handling sequences support both reproducibility and traceability.

Summary of Pan Loading and Handling Control Targets

| Parameter | Controlled Target |

|---|---|

| Pan centering deviation | Visually centered, no lateral offset |

| Pan rocking under probe | None detectable |

| Empty-pan baseline drift (%) | ≤ 3 |

| Onset shift due to misloading (°C) | ≤ ±0.5 |

| Dedicated handling tools | Ceramic tweezers only |

| Observable contamination artifacts | None present |

By enforcing controlled loading, stable seating, and contamination discipline, DSC Alumina Pans establish a consistent physical boundary that allows lid strategy and heating programs to perform predictably in subsequent stages.

Lid Strategy SOP: Open, Covered, Pinhole, or Sealed Configuration

Once pan loading is stabilized, lid strategy becomes the dominant factor governing mass transport and internal pressure during heating. Therefore, lid selection directly affects whether observed DSC events represent intrinsic sample behavior or container-controlled artifacts. Moreover, DSC Alumina Pans make lid-related effects more pronounced, which demands explicit configuration logic.

When to Use a Covered Alumina Pan

A covered alumina pan modifies the micro-environment above the pharmaceutical sample. Consequently, it is primarily used to reduce sample spattering and suppress convective disturbances during heating.

In routine DSC analysis of crystalline APIs with limited volatility, covered pans often improve baseline smoothness and peak symmetry. For instance, during melting-point confirmation studies, analysts have observed baseline noise reductions of approximately 20–30% when a simple cover is applied. However, covered configurations also delay gas release, and prolonged heating has produced shifted onsets by 1–2 °C when decomposition begins.

Accordingly, covered alumina pans should be selected only when mechanical stability outweighs the need for rapid gas escape.

Pinhole Lid Logic for Volatile or Decomposing Samples

Pinhole lids introduce a controlled release pathway for volatile species. Therefore, they balance pressure relief with partial containment of the sample atmosphere.

In pharmaceutical stability testing, pinhole lids have proven effective for APIs that decompose gradually between 250 °C and 400 °C. Experienced analysts report that controlled venting reduces false exothermic shoulders by limiting sudden gas expansion. In comparative runs, pinhole configurations have maintained onset repeatability within ±0.6 °C, whereas fully covered pans exceeded ±1.4 °C under identical conditions.

As a result, pinhole lids are preferred when decomposition is expected but complete exposure is undesirable.

Sealed Strategy and Associated Risk Boundaries

Fully sealed configurations fundamentally alter internal pressure conditions. Consequently, they are rarely appropriate for pharmaceutical DSC unless explicitly justified.

In practice, sealed alumina pans have produced abrupt exothermic spikes caused by pressure-induced secondary reactions rather than true phase transitions. In one compatibility assessment, repeated sealed runs generated irreproducible peaks varying by more than 3 °C between scans. Such behavior obscures interpretation and complicates method validation.

Therefore, sealed strategies should be avoided unless pressure effects are the explicit subject of investigation.

Lid Selection Influence on Data Interpretation

Lid choice not only affects physical containment but also shapes data interpretation boundaries. Hence, lid strategy must be recorded as a method-defining variable.

Analysts frequently report that inconsistent lid usage across runs produces apparent polymorphic differences that disappear when configuration is standardized. Furthermore, repeatability metrics improve markedly once lid selection is fixed early in method development. These observations reinforce the need for explicit lid control rather than ad hoc decisions.

Thus, lid configuration should be treated as a primary execution parameter rather than an accessory choice.

Summary of Lid Strategy Control Targets

| Configuration | Primary Purpose | Typical Impact on Repeatability |

|---|---|---|

| Open pan | Maximum gas release | Baseline noise ↑ |

| Covered pan | Suppress spatter and convection | Onset shift +1–2 °C |

| Pinhole lid | Controlled venting | Onset variability ≤ ±0.6 °C |

| Sealed pan | Pressure retention | High artifact risk |

By selecting lid configuration according to sample volatility and decomposition behavior, DSC Alumina Pans maintain controlled boundary conditions that preserve interpretability across pharmaceutical DSC workflows.

Atmosphere and Purge Gas SOP for Pharmaceutical DSC Interpretation

After lid configuration is fixed, purge atmosphere becomes the dominant variable controlling reaction pathways and baseline behavior. Therefore, gas selection and flow stability must be defined explicitly, because DSC Alumina Pans faithfully transmit atmosphere-driven effects into the heat-flow signal. Moreover, inconsistent purge conditions frequently explain run-to-run discrepancies that persist despite identical sample preparation.

Nitrogen Purge for Baseline Stability and Reaction Suppression

Nitrogen purge establishes an inert environment that minimizes oxidative reactions during heating. Consequently, it is the default atmosphere for most pharmaceutical DSC measurements focused on intrinsic thermal events.

In routine laboratory operation, stable nitrogen flow2 suppresses spurious exothermic features caused by surface oxidation or decomposition intermediates. Analysts commonly observe baseline noise reductions of 15–25% when nitrogen flow is stabilized before heating begins. Furthermore, onset temperature repeatability typically remains within ±0.5 °C when purge flow is constant throughout the run.

Accordingly, nitrogen purge should be selected when the analytical objective prioritizes baseline stability and reproducible interpretation.

Air Atmosphere for Oxidative Events

Air atmosphere introduces controlled oxidative conditions that reveal oxidation-driven thermal behavior. Therefore, it is used selectively when oxidation itself is the phenomenon of interest.

In pharmaceutical stress testing, air purge has exposed oxidative exotherms between 200 °C and 350 °C that are absent under nitrogen. Experienced analysts note that these events often increase apparent enthalpy by 5–10% compared to inert conditions. However, uncontrolled air exposure can also broaden peaks and shift onsets by more than ±1.0 °C, complicating interpretation.

Thus, air atmosphere should be reserved for targeted oxidative assessments rather than routine DSC characterization.

Switching Atmospheres Without Losing Comparability

Comparative nitrogen-versus-air studies are common during pharmaceutical development. However, switching atmospheres introduces additional variables that must be controlled to preserve comparability.

In practice, purge transitions performed without re-equilibration frequently generate baseline drift exceeding 5%. Laboratories that allow sufficient stabilization time before data collection report consistent peak alignment across atmospheres. Maintaining identical sample mass, lid configuration, and heating rates further reduces interpretive ambiguity.

Therefore, atmosphere switching must be executed as a controlled method step rather than an incidental adjustment.

Purge Flow Stability and Operational Discipline

Beyond gas type, purge flow stability directly affects heat-flow interpretation. Consequently, fluctuations in flow rate introduce thermal noise unrelated to sample behavior.

During multi-run studies, analysts have linked intermittent baseline waviness to purge flow instability rather than instrument malfunction. Stabilized flow conditions reduce baseline drift and improve repeatability across extended testing sequences. These improvements are especially evident when DSC Alumina Pans are reused across multiple experiments.

Hence, purge discipline is a prerequisite for meaningful pharmaceutical DSC data.

Summary of Atmosphere and Purge Gas Control Targets

| Parameter | Nitrogen Atmosphere | Air Atmosphere |

|---|---|---|

| Primary purpose | Inert baseline control | Oxidative behavior analysis |

| Baseline noise change (%) | −15 to −25 | +10 to +20 |

| Onset repeatability (°C) | ≤ ±0.5 | ≤ ±1.0 |

| Artifact risk | Low | Moderate to high |

| Suitability for routine DSC | High | Conditional |

By stabilizing purge atmosphere and flow conditions, DSC Alumina Pans translate controlled gas environments into reliable pharmaceutical DSC interpretation without introducing atmosphere-driven ambiguity.

Heating Program SOP: Ramp Rate, Holds, and Multi-Run Strategy

Once atmosphere conditions are stabilized, the heating program becomes the primary determinant of peak resolution and kinetic separation. Therefore, ramp rate selection and thermal holds must be defined deliberately, because DSC Alumina Pans respond predictably but unforgivingly to heating strategy choices. Moreover, inappropriate heating programs frequently explain irreproducible pharmaceutical DSC results even when all upstream variables are controlled.

Ramp Rate Selection for Tg, Melting, and Solid–Solid Transitions

Ramp rate governs the balance between thermal resolution and experimental throughput. Consequently, different thermal events require distinct ramp strategies rather than a single default rate.

In practical pharmaceutical DSC work, glass transition analysis benefits from slower heating, typically yielding clearer step changes and reduced baseline curvature. Analysts routinely report that ramp rates in the lower range improve Tg onset consistency to within ±0.4 °C, whereas aggressive rates often blur the transition. By contrast, melting events tolerate moderately higher rates without significant loss of interpretability, provided heat-flow equilibration remains stable.

Accordingly, ramp rate should be matched to the dominant thermal event rather than standardized across all analyses.

Isothermal Holds to Separate Overlapping Events

Isothermal holds interrupt continuous heating to allow kinetic processes to evolve independently. Therefore, they are effective for disentangling overlapping transitions in complex pharmaceutical systems.

During compatibility studies, analysts frequently insert short holds just below suspected decomposition onsets. These holds reveal whether subsequent peaks arise from delayed melting, recrystallization, or chemical degradation. In multiple development programs, the introduction of controlled holds has reduced peak overlap and clarified interpretation without increasing overall variability.

Thus, isothermal holds function as diagnostic tools rather than routine steps, deployed when thermal complexity is suspected.

First-Run versus Second-Run Interpretation Rules

Multiple heating cycles serve different analytical purposes in pharmaceutical DSC. Consequently, data interpretation must distinguish between first-run and subsequent-run information.

In standard practice, the first heating run captures thermal history and processing effects present in the sample. The second run, following controlled cooling, isolates intrinsic material behavior with reduced historical influence. Analysts consistently observe improved repeatability in second-run Tg and melting onsets, often tightening variability by 20–30% compared to first-run data.

Therefore, conclusions should explicitly state which run informs the reported pharmaceutical property.

Heating Program Consistency Across Replicate Runs

Consistency in heating programs ensures that observed differences reflect sample behavior rather than method drift. Hence, ramp rates, hold positions, and cycle counts must remain fixed once validated.

In multi-batch testing, even small deviations in ramp rate have produced measurable shifts in peak shape and enthalpy. Laboratories that lock heating programs early report fewer repeat tests and smoother method validation. These experiences underscore the importance of procedural discipline when DSC Alumina Pans are used.

Accordingly, heating programs should be documented and reused without modification unless re-validation is performed.

Summary of Heating Program Control Targets

| Parameter | Recommended Control |

|---|---|

| Ramp rate for Tg (°C/min) | Low, resolution-focused |

| Ramp rate for melting (°C/min) | Moderate, balanced |

| Onset repeatability (°C) | ≤ ±0.5 |

| Use of isothermal holds | Diagnostic, not routine |

| Variability reduction from second run (%) | 20–30 |

| Program consistency across runs | Fixed after validation |

By aligning ramp rates, holds, and run strategy with analytical objectives, DSC Alumina Pans deliver reproducible pharmaceutical DSC data without masking or exaggerating thermal events.

Artifact Control SOP: Preventing False Peaks, Baseline Drift, and Memory Effects

Even with heating programs validated, pharmaceutical DSC data can still be compromised by container- and process-induced artifacts. Therefore, artifact control must be treated as an execution-stage discipline rather than a post-analysis correction. Moreover, DSC Alumina Pans make artifacts easier to diagnose, provided preventive controls are applied consistently.

Volatilization and Decomposition Artifact Suppression

Volatilization and decomposition generate transient heat-flow disturbances that can masquerade as genuine thermal events. Consequently, suppression strategies must be selected before heating begins rather than inferred afterward.

In practical pharmaceutical DSC work, analysts frequently encounter small exothermic shoulders between 250 °C and 400 °C that disappear when lid strategy and mass are adjusted. For instance, reducing sample mass within the validated range and switching from a fully covered to a pinhole configuration has eliminated false peaks in repeated compatibility tests. Additionally, pre-drying hygroscopic samples has reduced early endothermic noise that previously distorted Tg interpretation.

Accordingly, artifact suppression is achieved through coordinated control of mass, lid configuration, and pre-conditioning rather than signal correction.

Baseline Drift Prevention Within the Method

Baseline drift reflects gradual changes in thermal boundary conditions during a DSC run. Therefore, prevention must be embedded within the method rather than addressed through mathematical correction.

During extended pharmaceutical DSC sequences, analysts often observe baseline slopes increasing after several runs. Empty-pan verification scans have revealed that drift exceeding 4–5% usually originates from seating changes, purge instability, or residue accumulation. Laboratories that revalidate empty-pan baselines between batches report significantly fewer ambiguous results and reduced rerun frequency.

Thus, baseline stability should be confirmed operationally before sample interpretation proceeds.

Memory Effects from Pan Reuse and Residue Accumulation

Memory effects arise when residues from prior samples influence subsequent measurements. Consequently, reuse criteria must be defined explicitly when DSC Alumina Pans are employed.

In real laboratory settings, reuse without inspection has led to subtle peak broadening and shifted onsets during later runs. Analysts have documented effective thermal mass increases of approximately 10–15% when residue is present, producing delayed transitions that mimic kinetic effects. Implementing visual inspection and empty-pan baseline checks has consistently prevented these misinterpretations.

Therefore, reuse decisions should be governed by measurable criteria rather than reuse count alone.

Operational Experience with Artifact Identification

Experienced analysts recognize artifacts through characteristic signatures rather than isolated anomalies. Hence, artifact awareness develops through pattern recognition across runs.

For example, true phase transitions remain consistent in temperature and shape across controlled repeats, whereas artifacts often shift position or disappear after minor procedural adjustments. Teams that document these patterns report faster root-cause identification and higher confidence in pharmaceutical conclusions. Such experiential learning reinforces the value of structured artifact control.

Accordingly, artifact recognition should be integrated into routine DSC execution rather than treated as exceptional troubleshooting.

Summary of Artifact Control Targets

| Artifact Source | Preventive Control | Acceptance Indicator |

|---|---|---|

| Volatilization | Mass and lid optimization | No transient shoulders |

| Decomposition | Pinhole or open configuration | Stable onset position |

| Baseline drift | Empty-pan verification | Drift ≤ 3% |

| Residue memory | Visual inspection and cleaning | No peak shift |

| Repeat-run artifacts | Procedural consistency | Reproducible curves |

By embedding artifact prevention into execution discipline, DSC Alumina Pans enable pharmaceutical DSC data that reflect sample behavior rather than method-induced distortion.

Data Acceptance Criteria for Pharmaceutical DSC Using Alumina Pans

After execution controls are applied, objective acceptance criteria are required to determine whether DSC results are interpretable. Therefore, data validity must be judged against predefined thresholds rather than visual preference or isolated experience.

-

Repeatability targets for onset, peak temperature, and enthalpy

Acceptable pharmaceutical DSC data require consistent thermal markers across replicate runs. In controlled alumina pan execution, onset temperature repeatability should remain within ±0.5 °C, while peak temperature variation should not exceed ±0.8 °C across repeats. Enthalpy variation is considered acceptable when maintained within ±4%, as larger deviations typically indicate mass, contact, or heating inconsistencies rather than material behavior.

Accordingly, repeatability thresholds function as the first-pass filter for data acceptance. -

Baseline noise and drift limits during analysis

Baseline quality defines the interpretive clarity of all DSC events. In practice, baseline drift during a single run should remain below 3%, and baseline noise should not obscure low-enthalpy transitions such as glass transitions. When these limits are exceeded, subsequent peak interpretation becomes unreliable regardless of apparent transition shape.

Therefore, baseline stability must be confirmed before thermal conclusions are recorded. -

Documentation requirements for method traceability

Traceable pharmaceutical DSC results depend on consistent documentation of execution variables. Essential records include pan type, lid configuration, sample mass, purge atmosphere, heating program, and any pre-conditioning steps. Missing or inconsistent records frequently correlate with irreproducible results during method review or transfer.

Thus, documentation completeness is an integral acceptance criterion rather than an administrative formality.

These acceptance criteria establish a clear decision boundary, enabling analysts to determine whether DSC Alumina Pan results are suitable for pharmaceutical interpretation or require re-execution.

Engineering Takeaway for User-Side Execution

Controlled pharmaceutical DSC execution depends on disciplined variable management rather than instrument adjustment. Therefore, user-side decisions determine whether DSC Alumina Pans function as reliable thermal boundaries or expose hidden method weaknesses.

-

Execution discipline outweighs container selection

DSC Alumina Pans provide chemical inertness and geometric stability, yet they do not compensate for inconsistent execution. In practice, laboratories that standardized preparation, loading, lid strategy, purge atmosphere, and heating programs achieved repeatable curves even across different operators. Conversely, ad hoc execution produced divergent results despite identical materials and instruments.

Accordingly, execution discipline is the primary determinant of data reliability. -

Early-stage controls prevent downstream interpretation errors

Most DSC artifacts originate upstream during preparation and loading rather than during data analysis. Analysts who verified empty-pan baselines, contact stability, and purge conditions before sample runs reported fewer false peaks and reduced rerun frequency. These preventive actions require minimal time yet eliminate substantial interpretive ambiguity.

Therefore, front-loaded controls offer the highest return on method robustness. -

Quantitative thresholds enable objective decision-making

Acceptance criteria transform subjective curve inspection into objective evaluation. When onset repeatability, baseline drift, and enthalpy variation remained within defined thresholds, pharmaceutical conclusions were consistently defensible during review. Exceeding these limits reliably indicated method deviation rather than material behavior.

Thus, quantitative thresholds anchor execution quality to measurable standards.

These principles consolidate the preceding SOP elements into a coherent execution mindset, preparing the ground for final interpretation and reporting.

Conclusion

In pharmaceutical DSC analysis, DSC Alumina Pans function as stable thermal boundaries rather than corrective tools. Ultimately, reproducible results emerge from disciplined control of preparation, loading, atmosphere, heating, and acceptance criteria rather than from pan material alone.

Before interpreting pharmaceutical DSC results, verify empty-pan baselines and execution thresholds. Controlled execution should always precede material-level conclusions.

FAQ

How much sample mass is recommended when using DSC Alumina Pans for pharmaceutical testing?

In most pharmaceutical DSC methods, milligram-level sample masses with relative deviation within ±10% provide stable heat-flow equilibration and reproducible enthalpy results.

Should a lid always be used with DSC Alumina Pans?

No. Lid selection depends on volatility and decomposition behavior, with open, covered, or pinhole configurations chosen to control gas release and artifact risk.

Does purge atmosphere affect DSC results when alumina pans are used?

Yes. Nitrogen purge typically improves baseline stability, while air atmosphere is reserved for targeted oxidative studies that require explicit interpretation control.

What indicates that a DSC run should be repeated rather than interpreted?

Onset repeatability exceeding ±0.5 °C, baseline drift above 3%, or inconsistent peak shapes across replicates indicate that execution variables require correction before interpretation.

References: