DSC alumina crucibles operate at μW-level sensitivity; therefore, even minor material variability can distort weak thermal signals. However, conventional crucibles often introduce hidden interference that accumulates across repeated measurements. Consequently, high-purity DSC alumina crucibles reduce measurement uncertainty by addressing these effects at their material origin.

DSC alumina crucibles with high purity play a decisive role in controlling measurement uncertainty in weak-signal thermal analysis. By minimizing impurity-driven variability, high-purity crucibles stabilize thermophysical behavior, suppress abnormal thermal events, and improve batch-to-batch and long-term repeatability. As a result, experimental data become more reliable, comparable, and interpretable across demanding DSC applications.

Before refining temperature programs, calibration procedures, or data processing methods, uncertainty must first be traced back to its material source. Consequently, crucible purity emerges as a primary engineering variable that governs how much non-sample noise propagates into DSC measurements.

Experimental Uncertainty in DSC: Why Crucible Purity Becomes a Key Variable

Because DSC alumina crucibles operate within a μW-level detection window, any non-sample contribution can propagate directly into measured heat-flow signals. Therefore, understanding how material-related uncertainty originates is essential before discussing how high purity mitigates it.

-

Impurity Presence in Alumina Crucibles

Alkali metals, silicate phases, and trace transition metals are commonly present in standard DSC alumina crucibles at measurable levels. These impurities participate in heating processes through phase transitions, volatilization, or chemical interaction. As a result, they introduce additional heat-flow contributions that are unrelated to the sample itself. -

Variability of Thermophysical Properties

Impurities alter thermal conductivity and heat capacity locally within the crucible body. Consequently, heat transfer between the furnace, crucible, and sample becomes less uniform. This variability leads to baseline fluctuations and scan-to-scan inconsistencies even when experimental parameters remain unchanged. -

Accumulated Effects During Repeated Use

During repeated DSC cycles, impurities can migrate toward the surface or grain boundaries under thermal gradients. Over time, this migration amplifies baseline drift and noise levels. Therefore, crucible-related uncertainty is not static but increases progressively with continued use.

Together, these mechanisms explain why crucible purity directly governs the magnitude and stability of measurement uncertainty in DSC alumina crucibles.

How High Purity Improves Thermophysical Consistency and Compresses Uncertainty

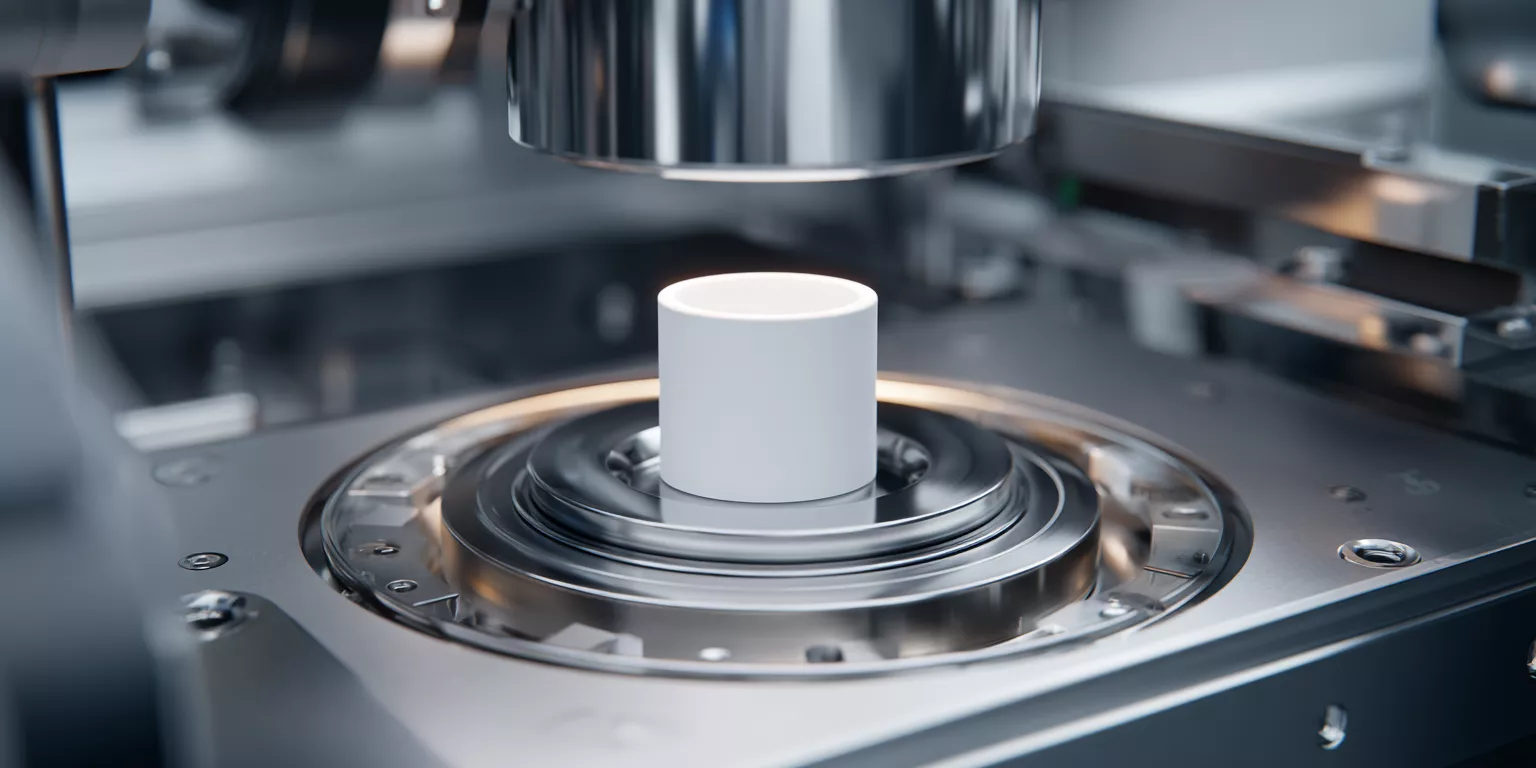

Because crucible-related uncertainty originates from unstable thermophysical behavior, purity must be evaluated in terms of how consistently heat is transferred and stored during DSC measurements. Moreover, high purity alters these properties in a predictable way, thereby compressing uncertainty at its physical source.

Thermal Conductivity Stability Enabled by High Purity

In alumina ceramics, thermal conductivity is governed by phonon transport through the crystal lattice. However, impurity phases act as scattering centers that shorten phonon mean free paths and introduce spatial variability. Consequently, lower-purity DSC alumina crucibles exhibit wider conductivity dispersion across their volume.

In comparative laboratory runs, engineers observed that 99.7% alumina crucibles produced noticeable scan-to-scan response lag variations at identical heating rates. By contrast, 99.99% high-purity crucibles showed smoother heat-flow rise profiles and more uniform peak alignment. Therefore, response time constants became more reproducible under repeated thermal programs.

As a result, high purity directly stabilizes the dynamic thermal response of DSC alumina crucibles, reducing uncertainty before any data correction is applied.

Thermal Conductivity Comparison by Purity

| Alumina Purity (%) | Thermal Conductivity (W/m·K) | Variability Range (%) |

|---|---|---|

| 99.7 | 20–25 | ±15 |

| 99.9 | 25–30 | ±8 |

| 99.99 | 30–35 | ±4 |

Heat Capacity Accuracy and Baseline Correction

Heat capacity measurements in DSC rely on accurate blank subtraction, which assumes stable and predictable crucible Cp behavior. However, impurity phases contribute additional heat capacity that varies with temperature. Consequently, baseline curvature increases and blank correction becomes less effective.

During polymer glass transition experiments, analysts found that lower-purity crucibles produced inconsistent Cp baselines across different heating rates. Conversely, high-purity DSC alumina crucibles exhibited nearly overlapping blank curves, allowing more reliable subtraction. As a result, Tg determination accuracy improved from approximately ±2 °C to ±0.5 °C under controlled conditions.

Therefore, purity enhances not only absolute accuracy but also confidence in comparative thermal analysis.

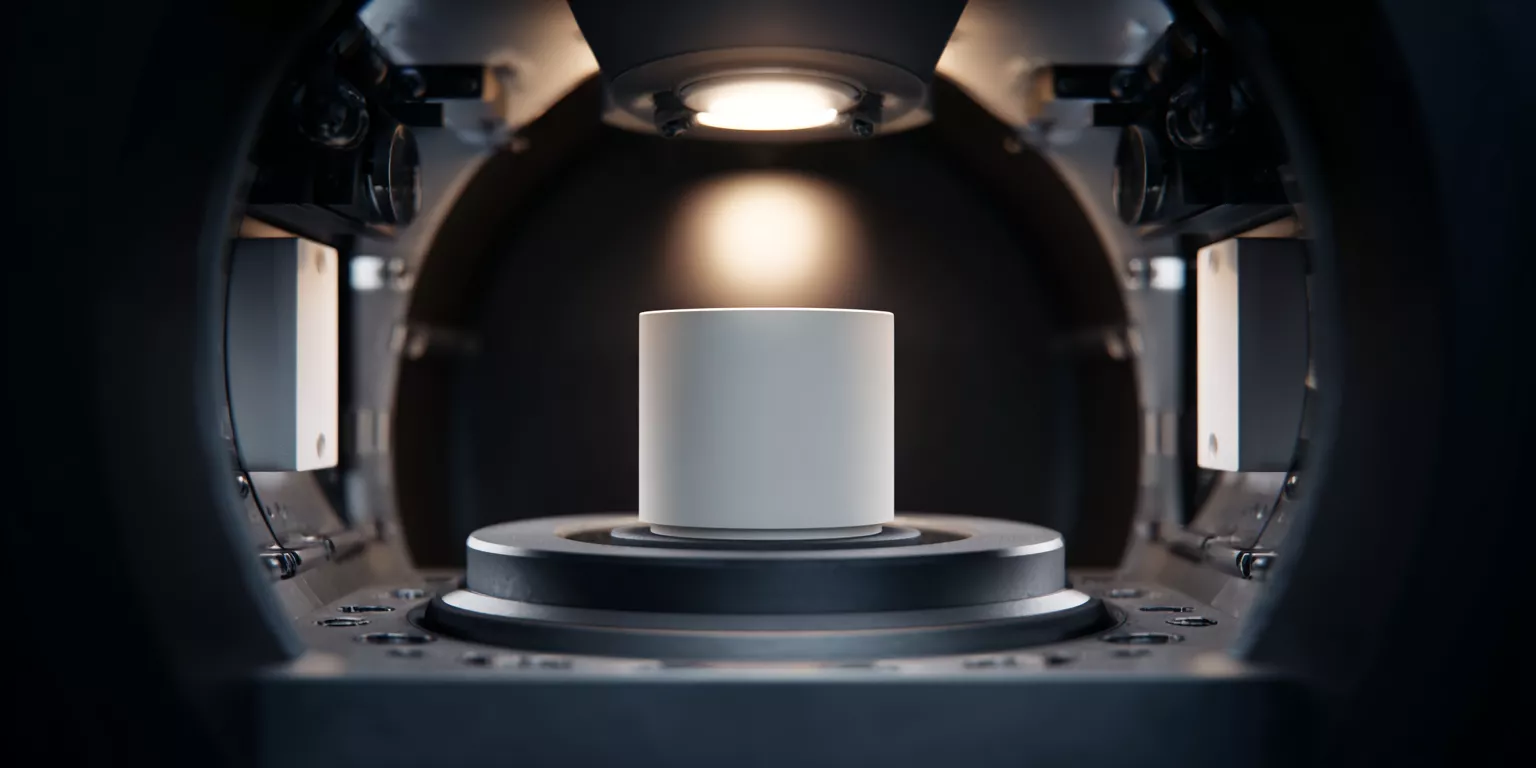

High-Temperature Structural Stability and Heat-Flow Integrity

At elevated temperatures, impurities may volatilize or soften, weakening grain boundaries and promoting creep deformation. These changes alter crucible geometry and disrupt thermal contact with the DSC sensor. Consequently, heat-flow integrity degrades during long or repeated high-temperature runs.

Tests conducted between 800 °C and 1600 °C demonstrated that high-purity alumina crucibles retained dimensional stability after extended dwell times. Meanwhile, standard-grade crucibles showed measurable distortion and increased baseline drift. Hence, high purity preserves both structural integrity and thermal consistency across demanding DSC conditions.

How High Purity Systematically Eliminates Abnormal Thermal Signals

Because abnormal thermal signals directly mask or mimic genuine sample behavior, their elimination represents a critical pathway for reducing DSC uncertainty1. Moreover, high-purity DSC alumina crucibles address these artifacts by removing the impurity-driven mechanisms that generate false heat-flow events.

Summary of Abnormal Thermal Signals Eliminated by High-Purity DSC Alumina Crucibles

| Impurity Type | Typical Impurity Level | Temperature Range Affected (°C) | Abnormal Thermal Signal Type | Impact on DSC Data | Purity Threshold for Elimination (%) |

|---|---|---|---|---|---|

| Alkali Metals (Na, K) | 0.1–0.5% | 200–600 | Spurious endo/exothermic peaks | False polymer transitions, distorted kinetics | ≥99.9 |

| Silicate Phases (SiO₂–Al₂O₃) | 0.05–2% | 750–850 | Glass-transition-like baseline steps | Misidentified ceramic phase changes | ≥99.9 (Si <100 ppm) |

| Transition Metals (Fe, Ti, Cr) | 200–1000 ppm | 300–1200 | Catalytically shifted reaction peaks | OIT error up to 30–50% | ≥99.99 |

Elimination of Alkali-Metal Low-Temperature Interference

Alkali metal impurities such as sodium and potassium commonly exist in lower-purity alumina as residual fluxes or secondary phases. During DSC heating, these species may undergo hydration–dehydration reactions or solid–solid transitions within the 200–600 °C range. Consequently, spurious endothermic or exothermic peaks appear, often overlapping with polymer transitions or crystallization events.

In practical laboratory experience, analysts observed that DSC alumina crucibles containing approximately 0.3% alkali impurities produced repeatable but non-sample-related peaks near 350–550 °C. When crucible purity was increased from 99.7% to 99.9%, these features disappeared entirely under identical test conditions. As a result, kinetic interpretations of polymer crystallization became consistent across repeated runs.

Therefore, high purity suppresses alkali-driven low-temperature artifacts, restoring confidence in DSC data interpretation.

Suppression of Silicate Glass-Transition Artifacts

Silicon-containing impurities form SiO₂–Al₂O₃ glassy or eutectic phases within the alumina matrix. These phases exhibit glass-transition-like behavior around 750–850 °C. However, such transitions can be mistakenly attributed to ceramic phase changes or sintering reactions of the sample.

During ceramic materials research, engineers reported unexplained baseline inflections and weak endothermic steps near 800 °C when using standard-grade crucibles. By contrast, high-purity DSC alumina crucibles with silicon content controlled below 100 ppm showed no such features. Consequently, sintering onset temperatures and phase evolution could be evaluated without container-induced ambiguity.

Thus, reducing silicate content through high purity directly removes a major source of high-temperature false signals.

Removal of Transition-Metal Catalytic Effects

Trace transition metals2, particularly iron, titanium, and chromium, introduce catalytic activity into DSC environments. These species can accelerate oxidation or decomposition reactions, thereby shifting reaction onset temperatures and altering measured enthalpies. In oxidation studies, such effects may lead to substantial underestimation or overestimation of material stability.

Experimental comparisons demonstrated that crucibles containing 200–500 ppm iron caused oxidation induction times to deviate by as much as 30–50%. When purity levels exceeded 99.99%, these catalytic pathways were effectively suppressed. Consequently, oxidation kinetics reflected intrinsic sample behavior rather than container-induced acceleration.

Accordingly, high-purity DSC alumina crucibles are essential for eliminating catalytic interference in chemically sensitive thermal analyses.

How High Purity Enhances Batch-to-Batch Repeatability and Long-Term Stability

Because DSC alumina crucibles are often consumed and replaced in batches, consistency across production lots becomes a decisive factor for long-term data reliability. Moreover, high purity reduces compositional dispersion at its source, thereby stabilizing baseline behavior over time and across repeated use.

Summary of Repeatability and Stability Improvements with High-Purity DSC Alumina Crucibles

| Alumina Purity (%) | Batch-to-Batch Impurity Std. Dev. (%) | Baseline Overlap Bandwidth (µW) | Cycles to Noticeable Drift (n) | Long-Term Stability Assessment |

|---|---|---|---|---|

| 99.7 | ~0.15 | ±50 | <40 | Poor |

| 99.9 | ~0.03 | ±15 | ~80 | Good |

| 99.99 | <0.01 | ±5 | >100 | Excellent |

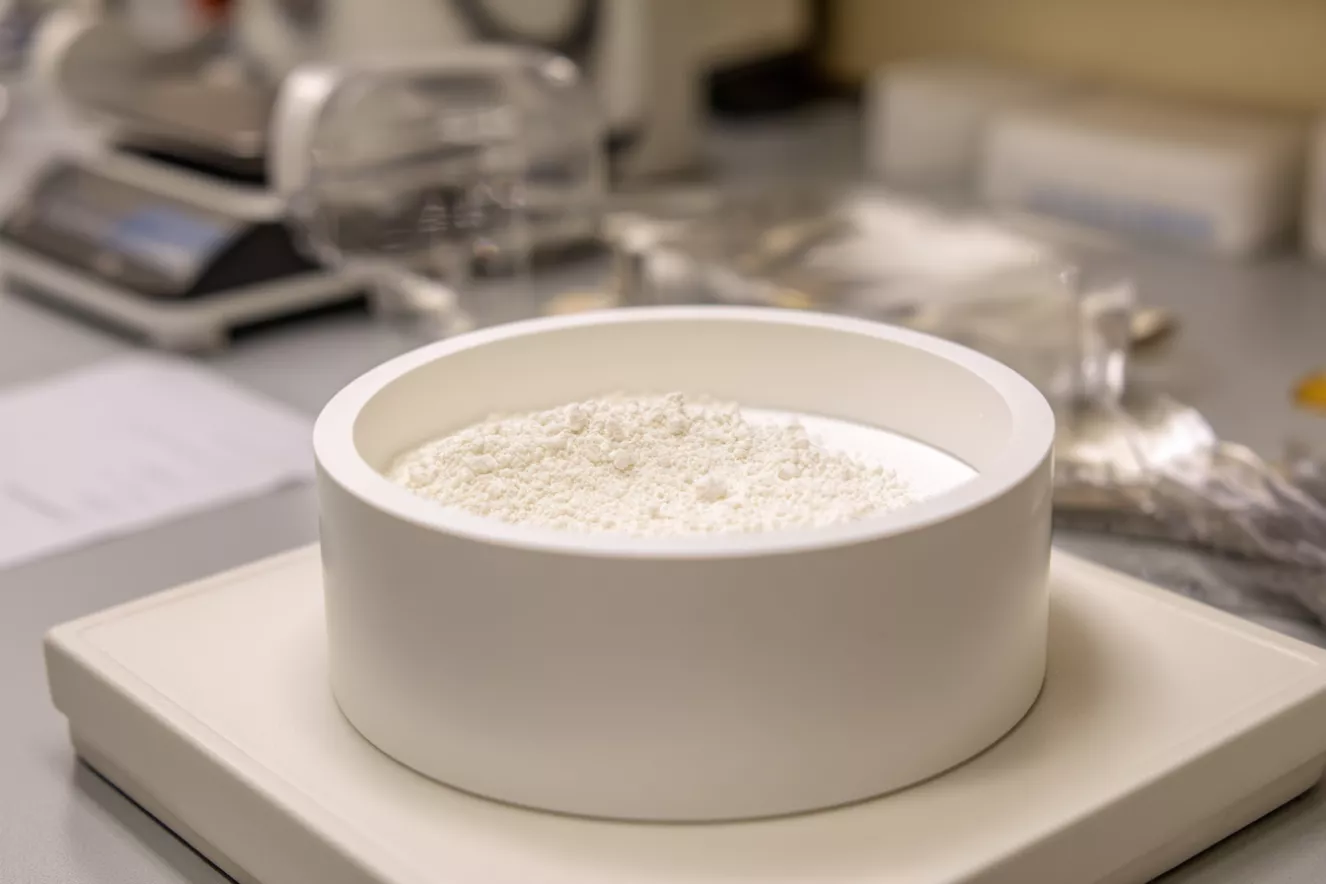

Compositional Uniformity Achieved Through High-Purity Manufacturing

In conventional alumina production, impurity levels fluctuate with raw material sources and firing conditions. Consequently, standard-grade DSC alumina crucibles exhibit measurable batch-to-batch variation in thermal response. This variation manifests as baseline offsets or noise differences even when experimental setups are unchanged.

In contrast, high-purity crucibles rely on refined alumina feedstock and tightly controlled sintering profiles. As a result, impurity distributions remain narrow across batches. Engineers performing routine blank scans observed that baseline alignment improved significantly when switching from 99.7% to 99.9% purity, even across different production lots.

Therefore, high purity converts batch variation from an uncontrolled risk into a predictable, manageable parameter.

Multi-Batch Baseline Overlap Performance

To quantify repeatability, laboratories often perform empty-pan DSC scans using crucibles from multiple batches. In such tests, baseline overlap width provides a direct indicator of crucible-induced uncertainty.

During a ten-batch comparison study, standard-grade crucibles showed wide baseline envelopes, whereas high-purity crucibles produced tightly clustered curves. Consequently, inter-batch correction factors became unnecessary, simplifying method validation.

Thus, high purity directly translates into improved baseline overlap and reduced cross-batch uncertainty.

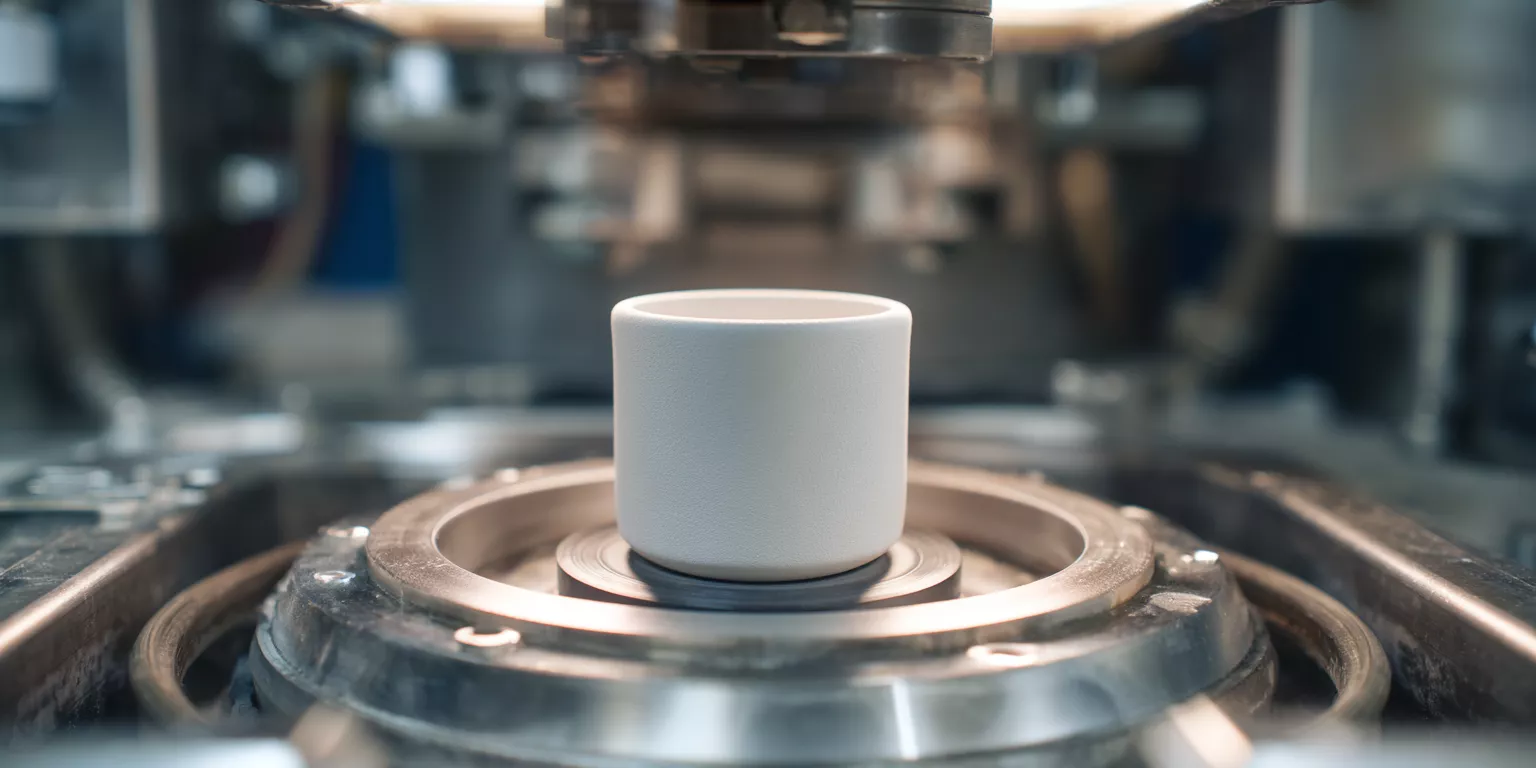

Stability Under Repeated Thermal Cycling

Long-term stability depends not only on initial purity but also on how that purity resists degradation during use. Impurities tend to migrate, volatilize, or concentrate at surfaces under repeated heating, amplifying noise over time.

High-purity DSC alumina crucibles demonstrated extended usable lifetimes under repeated thermal cycling. After 100 heating cycles, baseline drift remained within acceptable limits, whereas lower-purity crucibles exceeded rejection thresholds. Hence, high purity preserves stability throughout the crucible’s service life.

Practical Evidence: How High Purity Reduces Uncertainty in Critical DSC Applications

Because uncertainty reduction must ultimately be demonstrated in real measurements, application-level evidence provides the strongest validation of high-purity DSC alumina crucibles. Moreover, weak signals and chemically sensitive systems amplify crucible-related effects, making purity-driven improvements directly observable.

Uncertainty Reduction in Key DSC Applications Using High-Purity Alumina Crucibles

| Application Scenario | Typical Signal Magnitude | Primary Uncertainty Source | Observed Uncertainty with Standard Purity | Uncertainty with High Purity | Recommended Purity (%) |

|---|---|---|---|---|---|

| Weak Tg Detection | 0.1–0.3 J/g·K | Baseline noise | ±2 °C Tg variation | ±0.5 °C Tg variation | ≥99.9 |

| Trace Polymorphism | 0.5–2 J/g | False baseline events | Inconsistent detection | Reliable detection | ≥99.95 |

| High-Temperature Oxidation | Reaction-rate dependent | Catalytic impurity effects | 30–50% OIT error | <5% deviation | ≥99.99 |

Precise Detection of Weak Glass Transition Events (Tg)

In polymer systems with low amorphous content or minor plasticizer additions, glass transition signals often fall within 0.1–0.3 J/g·K. Under these conditions, baseline noise introduced by the crucible can exceed the signal itself. Consequently, Tg onset and midpoint determinations become highly uncertain.

During comparative measurements, laboratories observed that standard-grade crucibles produced Tg variability exceeding ±2 °C across repeated runs. When high-purity DSC alumina crucibles (≥99.9%) were used, baseline smoothness improved markedly. As a result, Tg precision tightened to within ±0.5 °C, enabling reliable evaluation of formulation-level changes.

Thus, high purity directly converts marginal Tg detection into a reproducible analytical outcome.

Detection of Trace Polymorphism Below 1%

Pharmaceutical and fine-chemical materials frequently exhibit polymorphic transitions with enthalpies as low as 0.5–2 J/g. At concentrations below 1%, these transitions are easily obscured by container-induced artifacts. False positives or negatives are therefore common when crucible purity is insufficient.

In controlled studies, analysts found that crucibles below 99.9% purity generated sporadic baseline features that overlapped polymorphic transitions. By contrast, crucibles with purity ≥99.95% delivered stable baselines across multiple batches. Consequently, trace polymorphs became consistently detectable without excessive signal averaging.

Accordingly, high purity enables confident interpretation of weak solid–solid transitions.

Accurate Evaluation of High-Temperature Oxidation Kinetics

Oxidation induction time (OIT) and related kinetic parameters are particularly sensitive to catalytic effects. Transition-metal impurities in crucibles can accelerate oxidation reactions, leading to systematic underestimation of material stability by 30–50%.

In high-temperature DSC experiments between 800 °C and 1200 °C, engineers reported that only ultra-high-purity alumina crucibles (≥99.99%) suppressed catalytic acceleration effectively. Consequently, measured oxidation rates aligned with independent isothermal tests. Therefore, high purity becomes indispensable for accurate high-temperature kinetic analysis.

Purity Grade Selection

Because uncertainty reduction follows diminishing returns, selecting purity must align with the measurement objective rather than defaulting to the highest grade. Moreover, matching purity to required precision prevents both under-specification and unnecessary over-engineering in DSC alumina crucibles.

Summary of Purity Selection Criteria for DSC Alumina Crucibles

| Purity Grade (%) | Typical Impurity Level (%) | Uncertainty Reduction vs Baseline (%) | Relative Cost Factor (×) | Suitable DSC Applications |

|---|---|---|---|---|

| 99.7 | ~0.3 | Baseline reference | 1 | Teaching, preliminary screening |

| 99.9 | ~0.1 | 60–70 | 2–3 | R&D, quality control |

| 99.99 | ~0.01 | 85–90 | 8–12 | Precision research, standards |

Engineering Trade-Off Between Purity and Uncertainty Reduction

As alumina purity increases, impurity-driven variability decreases nonlinearly. Consequently, the largest uncertainty reduction occurs when moving from standard to high purity, while ultra-high purity delivers incremental gains suited to extreme sensitivity.

In routine laboratory practice, engineers observed that upgrading from 99.7% to 99.9% purity removed most baseline instability. By contrast, moving from 99.9% to 99.99% primarily benefited experiments operating near detection limits or under catalytic risk.

Therefore, purity selection should be driven by uncertainty tolerance rather than material specification alone.

Decision Logic Based on Measurement Requirements

When allowable uncertainty remains relatively wide, standard-grade crucibles may suffice. However, as precision targets tighten, crucible-related variability rapidly dominates total uncertainty.

In method development workflows, analysts often adopt a tiered approach: initial screening with 99.7%, validation with 99.9%, and final confirmation using ≥99.99% when required. Consequently, resources are allocated efficiently while maintaining data credibility.

Thus, a structured decision logic ensures purity is applied where it delivers measurable value.

Lifecycle Cost Considerations

Although high-purity DSC alumina crucibles carry higher upfront cost, they reduce repeat experiments, troubleshooting time, and method revisions. Over extended use, these savings offset initial investment.

In long-term studies, laboratories reported fewer rejected runs and shorter validation cycles when adopting higher purity. Hence, lifecycle cost rather than unit price provides a more accurate economic perspective.

Quality Verification and Proper Use of High-Purity DSC Alumina Crucibles

Because high purity only reduces uncertainty when it is verified and preserved in practice, quality control and disciplined use are essential. Otherwise, handling- or verification-related errors can reintroduce variability into DSC alumina crucibles.

Summary of Verification and Usage Practices for High-Purity DSC Alumina Crucibles

| Control Stage | Verification or Practice | Typical Method | Impact on Measurement Uncertainty |

|---|---|---|---|

| Incoming Inspection | Purity confirmation | CoA review, ICP-OES/MS | Prevents batch-level variability |

| Pre-Use Validation | Baseline behavior check | Empty-pan DSC scan | Detects hidden interference |

| Handling Control | Contamination prevention | Gloves, ceramic tweezers | Preserves intrinsic purity |

| Cleaning & Reuse | Residue removal | Ultrasonic + high-temp firing | Maintains low noise over cycles |

| End-of-Life Decision | Drift-based rejection | Baseline deviation limits | Avoids degraded data quality |

-

Incoming Purity Verification

At procurement, purity claims must be supported by Certificates of Analysis specifying alumina content, trace impurity limits, and analytical methods. In experienced laboratories, these documents are supplemented by ICP-OES or ICP-MS spot checks on representative batches. Consequently, unsuitable crucibles can be identified before they influence baseline stability or sample measurements.

Therefore, incoming verification acts as the first control point against crucible-induced uncertainty. -

Handling and Pre-Treatment to Prevent Secondary Contamination

Even high-purity DSC alumina crucibles can lose their advantage if contaminated by oils, dust, or metallic contact during handling. Routine practice shows that high-temperature pre-conditioning effectively removes adsorbed species acquired during storage. As a result, baseline behavior remains stable across consecutive DSC runs.

Thus, correct handling preserves the intrinsic low-interference characteristics of high-purity crucibles. -

Cleaning, Reuse, and End-of-Life Criteria

Cleaning protocols directly affect how long crucibles maintain low-noise performance. Ultrasonic solvent cleaning removes organic residues, while high-temperature firing eliminates inorganic remnants that accumulate during use. However, once baseline drift exceeds predefined thresholds, crucibles must be retired regardless of visual appearance.

Consequently, end-of-life decisions should always be driven by data behavior rather than subjective inspection.

Conclusion

In essence, high-purity DSC alumina crucibles reduce uncertainty by stabilizing thermophysical behavior and suppressing impurity-driven interference. Consequently, data reliability improves at the material level before any analytical correction is applied.

If DSC measurements approach detection limits or demand strict repeatability, evaluating crucible purity becomes a practical optimization step. In such cases, selecting high-purity DSC alumina crucibles often delivers the fastest and most reliable uncertainty reduction.

FAQ

Why does a DSC alumina crucible with high purity show lower baseline drift over repeated runs?

A DSC alumina crucible with high purity contains significantly fewer mobile impurities that can migrate during heating. Consequently, thermophysical properties remain stable across cycles, and baseline drift is reduced at the material level. This stability cannot be fully achieved through cleaning alone in lower-purity crucibles.

Is a high-purity DSC alumina crucible necessary for weak thermal signals near the detection limit?

Yes, when heat-flow signals approach the μW range, container-induced noise can exceed the signal itself. A high-purity DSC alumina crucible minimizes impurity-driven interference, thereby preserving weak transitions such as low-enthalpy Tg or minor phase changes. In such cases, purity directly determines whether the signal is interpretable.

How can I verify that a DSC alumina crucible with high purity is actually reducing interference?

Verification typically involves empty-pan DSC scans and comparison of baseline smoothness across batches. High-purity DSC alumina crucibles consistently produce tighter baseline envelopes and improved overlap between runs. These observable behaviors confirm that purity is effectively reducing uncertainty.

When should a high-purity DSC alumina crucible be preferred over standard grades?

A high-purity DSC alumina crucible should be preferred whenever reproducibility, chemical sensitivity, or method validation is critical. This includes oxidation studies, polymorphism detection, and precision research. In these scenarios, purity functions as an uncertainty-control parameter rather than a material upgrade.

References: