A High Purity Ceramic Focus Ring is a precision-machined ceramic ring installed around the active process area inside a vacuum plasma or coating chamber to control edge conditions and protect surrounding hardware. By setting a defined boundary for the plasma or deposition zone.

High Purity Ceramic Focus Ring Benefits

-

Controlled seating geometry: Flatness and parallelism targets are held within the agreed tolerance band so the high purity ceramic focus ring sits fully supported on the chamber seat, reducing rocking, uneven clamp load and distortion during thermal cycling.

-

Engineered edge protection: Defined chamfers or radii on inner and outer edges limit micro-chipping during handling and installation, helping the ring survive repeated tool opens and rebuilds without generating loose fragments.

-

Surface zoning option: Smooth functional faces and optional textured capture zones can be specified on the same focus ring so that critical sealing or seating areas remain clean while peripheral regions are better able to retain deposits and reduce particle return.

-

Predictable wear locations: Ring cross-section, step height and surface finish can be designed so that erosion is concentrated in expected high-flux zones near the inner or outer edge, making wear patterns easier to monitor and replacement timing easier to plan.

-

Repeatable rebuild compatibility: Consistent control of OD/ID, height and key feature dimensions from batch to batch allows the high purity ceramic focus ring to be swapped during refurb cycles without re-tuning hardware, simplifying spares planning and chamber qualification.

High Purity Focus Ring Specifications

| High Purity Focus Ring | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-HP-YJH01 | Customize | |

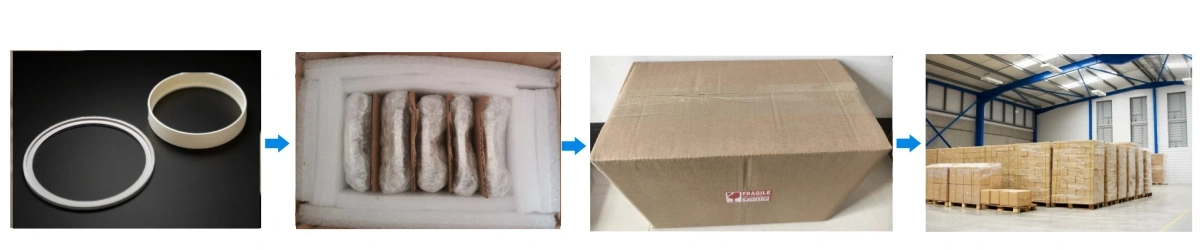

High Purity Focus Ring Packaging

- Clean wrap: ring is wrapped with clean film + soft interlayer to prevent face scratches.

- Shock protection: foam cutout supports ID/OD to avoid edge impact during transit.