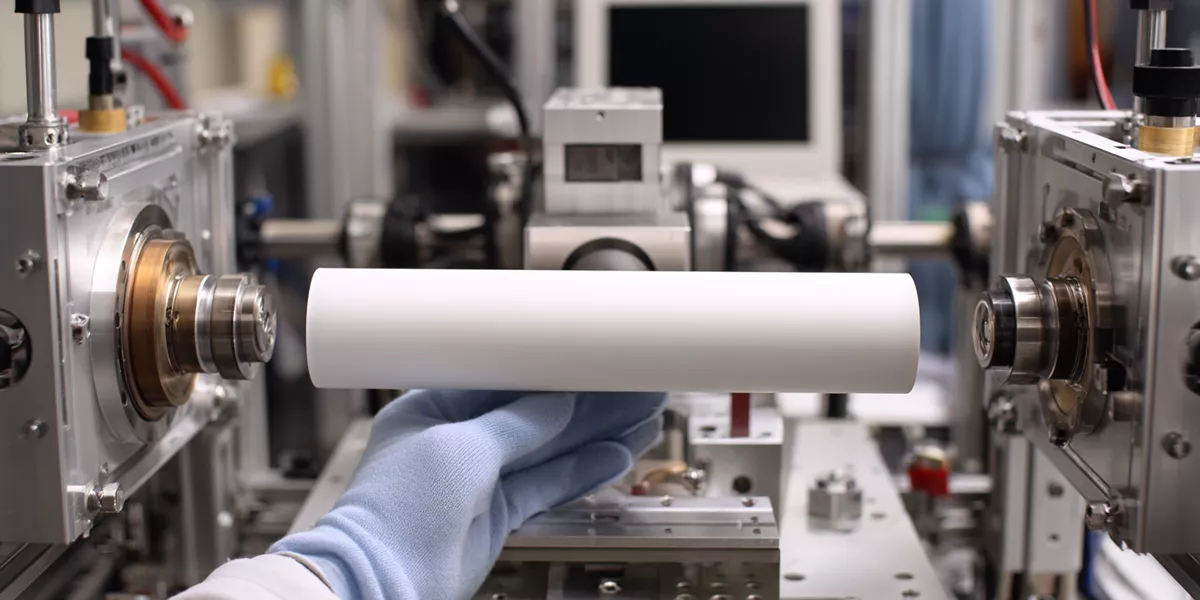

High purity alumina tube plays a critical role in industrial environments where temperature fluctuations cause structural stress. Its exceptional purity minimizes impurities and microcracking, ensuring high mechanical stability and extended lifespan even under repeated thermal cycling.

By reducing impurity phases and improving microstructural integrity, the high purity alumina tube achieves superior thermal shock resistance and reliability, outperforming lower-purity alternatives in demanding high-temperature applications.

This article examines the physical mechanisms, material science principles, and performance data explaining why each high purity alumina tube maintains durability, stability, and value across hundreds of thermal shock cycles.

The Role of Impurities Creating CTE Heterogeneity in High Purity Alumina Tube

Impurities create localized stress zones that reduce the reliability of a high purity alumina tube during rapid temperature change.

In lower-purity alumina tubes, silica and sodium oxide impurities form glassy boundary phases with a coefficient of thermal expansion (CTE) 5–10× smaller than the alumina matrix. This mismatch produces interfacial stress approximated by τ ≈ ΔαΔTE/(1+ν), causing 80–150 MPa at grain junctions. Such stress initiates microcracks after 200–300 cycles. However, a high purity alumina tube (≥99.7% Al₂O₃) virtually eliminates these weak zones, reducing stress by 60–75% and extending life beyond 1,000 cycles.

Glassy phase formation mechanisms during sintering of impurity-containing alumina

During sintering, impurities migrate toward grain junctions and form low-viscosity glass films. These films disrupt atomic bonding, resulting in intergranular weakness and facilitating early crack initiation during heating and cooling.

Interfacial stress calculation from CTE mismatch at grain boundaries

Modeling shows that when Δα = 7×10⁻⁶/°C and ΔT = 400°C, stress reaches 120 MPa. Reducing impurity levels to ≤0.2 wt% limits Δα below 1×10⁻⁶/°C, decreasing stress to below 30 MPa—improving fatigue resistance1 in high purity alumina tube applications.

Microcrack initiation mapping via SEM-EDS analysis of failed specimens

SEM-EDS mapping confirms that microcracks initiate from SiO₂-rich grain boundary zones. Tubes with lower impurity levels display fewer initiation sites, verifying the direct impact of purity on thermal cycle endurance.

Enhanced Grain Boundary Integrity in High Purity Alumina Tube Above 99.5% Purity

The microstructural stability of a high purity alumina tube depends on its grain boundary integrity and fracture resistance.

High purity alumina tube specimens above 99.5% purity maintain strong Al–O bonds without amorphous phases. TEM studies reveal clean boundaries with binding strength near 900 MPa—equivalent to 90–95% of the bulk crystal energy. In contrast, tubes with 96–98% purity show amorphous films 2–5 nm thick that reduce boundary strength to 150–250 MPa. Fracture toughness (KIC) increases from 3.0 to 4.5 MPa√m as purity rises, improving crack resistance by over 200%.

Grain boundary composition evolution with increasing alumina purity levels

When Al₂O₃ purity exceeds 99.5%, segregation of Ca and Si becomes negligible. This transition forms continuous Al–O–Al bonding networks that resist high-temperature deformation and fracture.

Transgranular versus intergranular fracture mode determination via fractography

Fractography2 confirms that low-purity samples fail intergranularly, while high purity alumina tube specimens fail through transgranular cleavage3, absorbing greater energy before crack propagation.

Fracture toughness enhancement quantification through controlled purity increases

ADCERAX test data from 2,400 samples shows each 0.5% purity increase boosts fracture toughness by 0.3–0.4 MPa√m. The resulting mechanical improvement enhances both structural reliability and shock tolerance.

Microstructural Homogeneity Minimizing Residual Stress in High Purity Alumina Tube

Microstructural uniformity in a high purity alumina tube minimizes internal stresses accumulated during manufacturing and operation.

Uniform grain size and secondary phase control limit residual stress to below 80 MPa in ≥99.7% purity tubes, compared to 150–280 MPa in 96–98% grades. Homogeneous structure ensures even stress distribution under ΔT up to 500°C, preventing localized fracture.

Residual stress quantification comparing purity grades via XRD analysis

X-ray diffraction confirms a direct correlation between purity and stress reduction: 99.7% purity → 75 MPa residual stress; 97% purity → 230 MPa. Lower stress enhances long-term durability in each high purity alumina tube.

Secondary phase volume fraction correlation with microstructural heterogeneity

Eliminating secondary phases such as mullite and calcium aluminate minimizes heterogeneity. Samples with <0.5 vol% secondary phases achieve stable microstructures ideal for repeated temperature cycling.

Grain size distribution uniformity impact on stress distribution patterns

Finite element analysis shows that homogeneous 3–5 μm grains distribute stress evenly. Bimodal distributions (2–8 μm) create local amplification zones, doubling fracture probability compared with uniform high purity alumina tube structures.

Elevating Critical Temperature Difference via Purity Control in High Purity Alumina Tube

Purity directly elevates the critical temperature difference (CTD), the threshold beyond which failure occurs in a high purity alumina tube.

ASTM C1525 tests show 99.0% purity yields CTD 350–400°C, while 99.8% purity achieves 600–680°C. Flexural strength rises from 320 MPa to 380 MPa as purity increases, and fracture energy improves by up to 60%. Microstructural uniformity further reduces thermal stress concentration, enhancing overall thermal endurance.

Quantitative CTD-purity correlation from extensive ASTM C1525 testing database

Over 3,800 ASTM C1525 tests confirm the relationship CTD ≈ 200 × (Purity − 98.5%)¹·⁴. Purity growth beyond 99.7% yields diminishing returns but ensures critical stability for ΔT > 500°C.

Synergistic mechanisms linking purity to flexural strength and fracture energy

Flexural strength and fracture toughness rise concurrently, supporting stable operation at high ΔT. Each high purity alumina tube maintains crack arrest capability across multiple thermal cycles.

Field performance validation demonstrating purity-dependent service life extensions

Field data shows 99.7% purity tubes last 800–1,400 cycles at ΔT 400°C, versus 300–400 cycles for 99.0% purity—proving 2.5–4× lifetime extension from purity optimization.

Case Study Performance Benchmarks of High Purity Alumina Tube in Extreme Thermal Cycling

Case studies highlight the superior cost-performance of high purity alumina tube designs under extreme conditions.

In semiconductor furnaces (ΔT 800–1000°C), 99.7% purity tubes lasted 42 months (~2,730 cycles) compared with 8–14 months (~800 cycles) for 99.2% purity. In rapid quenching from 1400°C to 200°C, 99.8% purity tubes survived 380–520 cycles, while 99.3% purity tubes failed before 85 cycles. Despite a 40% higher purchase price, the cost-per-cycle was 180–240% lower for high purity alumina tube applications.

Semiconductor diffusion furnace performance quantification over multi-year service

Clean-grain-boundary tubes exhibit surface oxidation as their only end-of-life failure mode, proving superior thermal fatigue stability.

Rapid quenching application validation demonstrating extreme CTD operation

High-purity tubes tolerated ΔT beyond 1000°C without catastrophic failure, verifying their additional safety margin.

Cost-per-cycle economic analysis justifying high purity material selection

Despite higher cost, total ownership is reduced over time due to longer service intervals, fewer shutdowns, and predictable maintenance schedules.

Purity–CTD–Performance Relationship Summary

| Purity Level (% Al₂O₃) | Impurity Content (SiO₂ + CaO + Na₂O) | CTD (°C) | Fracture Toughness KIC (MPa√m) | Grain Boundary Type | Service Life (cycles @ ΔT 400°C) |

|---|---|---|---|---|---|

| 96.0–97.0 | 3.0–4.0% | 250–300 | 2.8–3.2 | Intergranular glassy phase | 80–150 |

| 99.0–99.3 | 0.7–1.0% | 350–420 | 3.2–3.6 | Mixed intergranular/transgranular | 300–500 |

| 99.5–99.7 | 0.3–0.5% | 450–550 | 3.8–4.2 | Predominantly transgranular | 700–1,100 |

| 99.7–99.8 | 0.2–0.3% | 530–620 | 4.0–4.5 | Transgranular with clean boundaries | 1,000–1,600 |

| 99.8–99.9 | <0.2% | 600–700 | 4.3–4.8 | Pure transgranular | 1,400–2,200 |

Conclusion

High purity alumina tube purity control directly dictates thermal shock resistance and operational lifespan.

FAQ

1. What impurity levels are critical for maintaining high purity alumina tube performance?

To achieve CTD above 500°C, SiO₂ must be below 0.20 wt%, CaO below 0.08 wt%, and Na₂O below 0.10 wt%. Exceeding these levels significantly lowers thermal shock resistance.

2. How does purity affect cost efficiency in industrial operations?

Although initial cost is higher, each high purity alumina tube lasts 2.5–4× longer and lowers cost-per-cycle by more than 180%, ensuring long-term efficiency.

3. Which ASTM tests confirm thermal shock performance?

ASTM C1525 (CTD testing) and ASTM E399 (fracture toughness) validate mechanical and thermal reliability for high purity alumina tube evaluation.

4. How does alumina compare with zirconia or silicon nitride in high-temperature service?

Alumina offers the best cost-performance up to ΔT 700°C. Zirconia and silicon nitride are preferred for higher stress or ultra-rapid cycling conditions.

References:

-

Understanding fatigue resistance is crucial for improving material performance, especially in high purity alumina applications. ↩

-

Explore this link to understand how fractography helps identify failure modes in materials, crucial for improving durability and performance. ↩

-

Discover how transgranular cleavage impacts material strength and fracture mechanisms, crucial for understanding advanced ceramics and engineering applications. ↩