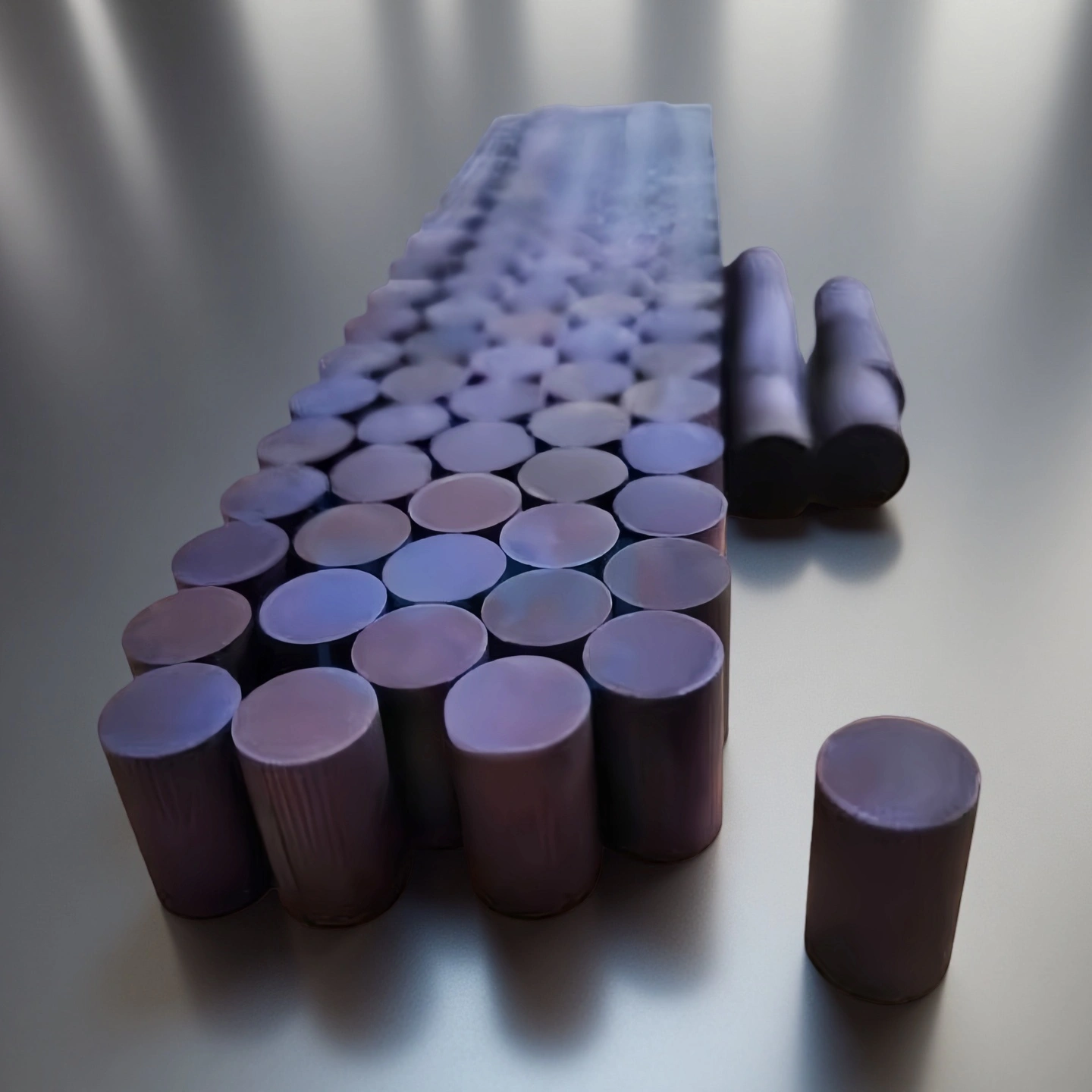

Lanthanum Hexaboride Rod (LaB₆ rod) is a solid lanthanum hexaboride ceramic rod used as raw stock for thermionic cathodes and electron-emitter parts in vacuum systems. It is typically cut, ground, and shaped into an emitter tip or cathode blank for electron guns (for example in electron microscopes) where stable electron emission at high temperature is required.

Lanthanum Hexaboride Rod Benefits

-

Emitter-blank suitability: The Lanthanum Hexaboride Rod (LaB6 rod) is supplied in a solid, uniform rod form that supports controlled tip grinding and repeatable emitter shaping. A consistent rod cross-section helps technicians reproduce the same cathode geometry across rebuild cycles, reducing trial-and-error during emitter preparation.

-

Thermionic-emission relevance: LaB6 rod is commonly selected as thermionic cathode stock when users need higher practical emission performance than standard tungsten filament workflows. The rod format makes it easier to define the emission area and tip profile, which directly influences beam stability and conditioning behavior in thermionic electron guns.

-

High-temperature stability: Lanthanum Hexaboride Rod is a refractory ceramic stock designed for high-temperature electron-source operation, where thermal load, repeated heating cycles, and localized hot zones can degrade many alternative materials. The material’s stability at elevated temperature supports longer-running sessions and more predictable performance in vacuum electron sources.

-

Surface condition sensitivity: LaB6 rod performance and grind consistency are strongly affected by surface condition and edge integrity. Specifying surface finish and controlling micro-chipping on handling-critical areas can reduce grinding variability, limit unintended defect initiation, and improve repeatability when producing fine emitter tips.

-

Lot consistency focus: For maintenance teams and rebuilders, lot-to-lot consistency matters because small variations can change grinding feel, final geometry, and conditioning time. A tightly defined LaB6 rod specification helps reduce rework, lowers replacement-to-replacement performance scatter, and supports standardized cathode programs across multiple instruments.

LaB₆ Rod Properties

| Lanthanum Hexaboride Ceramics (LaB6) | ||

| Property | Typical Value / Range | Performance Highlights / Notes |

| Melting Point | ≈ 2528 K (about 2250 °C) | Refractory ceramic that remains structurally stable at very high temperatures. |

| Density | ~4.7 g/cm³ | Compact, robust ceramic body suitable for small high-power cathodes and inserts. |

| Thermal Conductivity | ~47–60 W/m·K at 20 °C | Efficiently spreads heat across the emitter, reducing local hot spots. |

| Thermal Expansion (CTE) | ~6.2–6.5 ×10⁻⁶ /K (20–900 °C) | Good thermal shock resistance and predictable expansion for brazed or clamped assemblies. |

| Electrical Resistivity | ~15 μΩ·cm at 20 °C | High electrical conductivity, ideal for thermionic cathodes and other electron-emitting parts. |

| Typical Operating Temperature (Cathode) | ~1400–1800 °C in vacuum | Provides strong electron emission while maintaining long-term structural stability. |

| Emission Current Density | ~20–50 A/cm² at 1400–1800 °C | Delivers high beam brightness for electron microscopes, X-ray sources and plasma devices. |

| Work Function | ≈ 2.6–2.7 eV | Low work function enables high emission at lower temperatures than conventional tungsten cathodes. |

Lanthanum Hexaboride Rod Specifications

| Lanthanum Hexaboride Rod | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-LB-A4001 | Customize | |

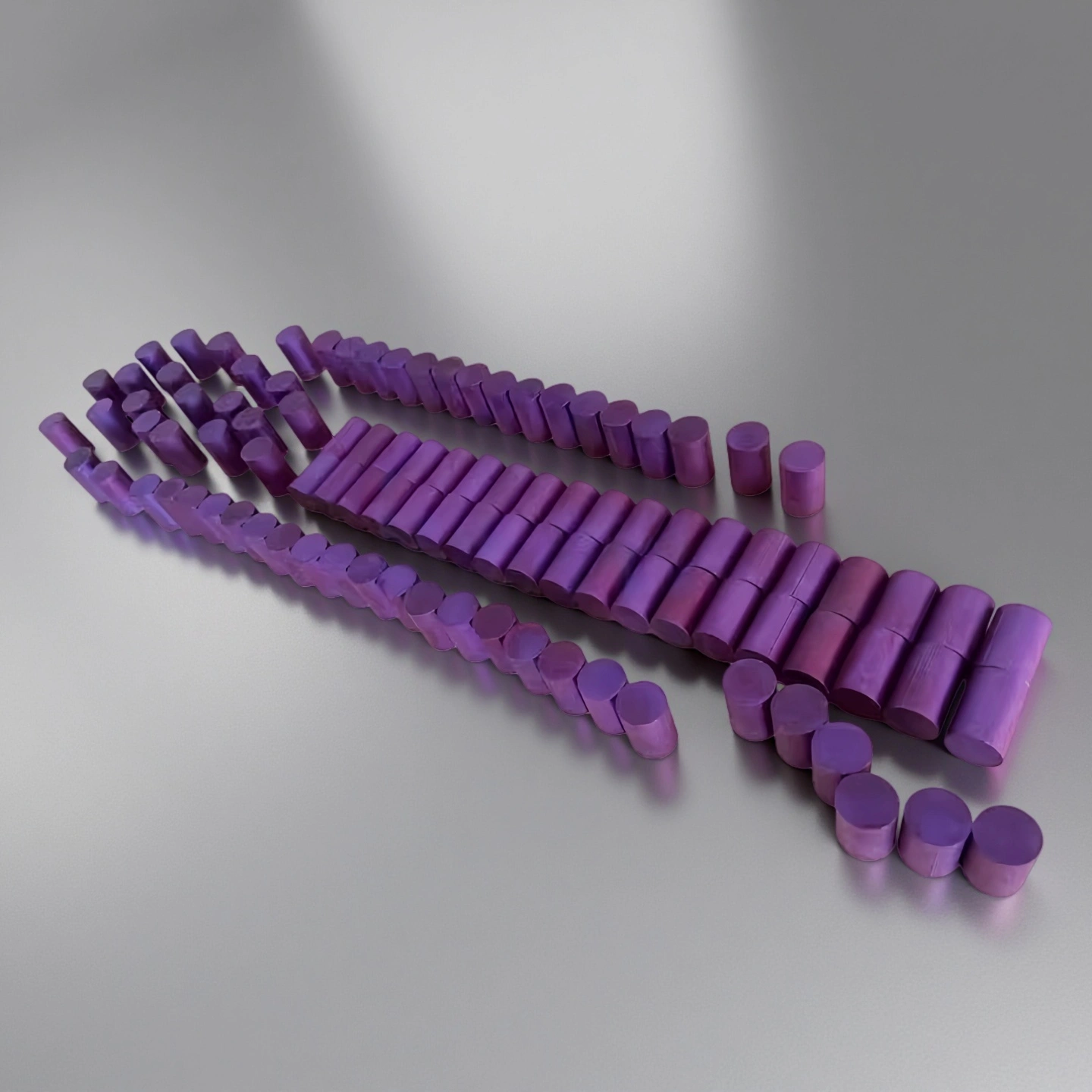

Lanthanum Hexaboride Rod Packaging

- Individual protection: each rod is separated to prevent edge contact and surface scratches.

- Shock control: buffered layers to reduce transit micro-chipping risk.