Alumina ceramic pin gauge is a precision-ground cylindrical gauge pin made from high-purity alumina (Al₂O₃), used as a dimensional reference to check hole diameter, position and fit (go/no-go) in machining, tooling and metrology. Compared with steel gauge pins, alumina ceramic pin gauges offer higher hardness, good wear and corrosion resistance and electrical insulation, so they maintain stable dimensions and measuring accuracy in coolant, humid or mildly corrosive environments.

Alumina Ceramic Pin Gauge Benefits

-

Stable Dimensions Under Load and Temperature

High-purity alumina combines high stiffness and low thermal expansion, so the gauge pin diameter remains stable during repeated use and moderate temperature variation. -

Wear-Resistant Measuring Surface

With Vickers hardness typically above 17 GPa, alumina ceramic pin gauges offer high resistance to abrasive wear, especially in environments with fine chips, dust or repeated insertion cycles. -

Corrosion-Free and Electrically Insulating

Alumina ceramics are chemically inert to many coolants and process media and provide high volume resistivity, which helps prevent rust-related drift seen with steel gauge pins. -

Consistent Surface Finish for Repeatable Measurement

Precision grinding and polishing can achieve low surface roughness, supporting repeatable contact with bushings, holes and calibration blocks during go/no-go checks. -

Support for Non-Standard Geometry and Sets

Alumina ceramic pin gauges can be supplied as individual pins, step pins, or application-specific sets, aligned with the tolerances and increments specified in your inspection documentation.

Alumina Pin Gauge Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

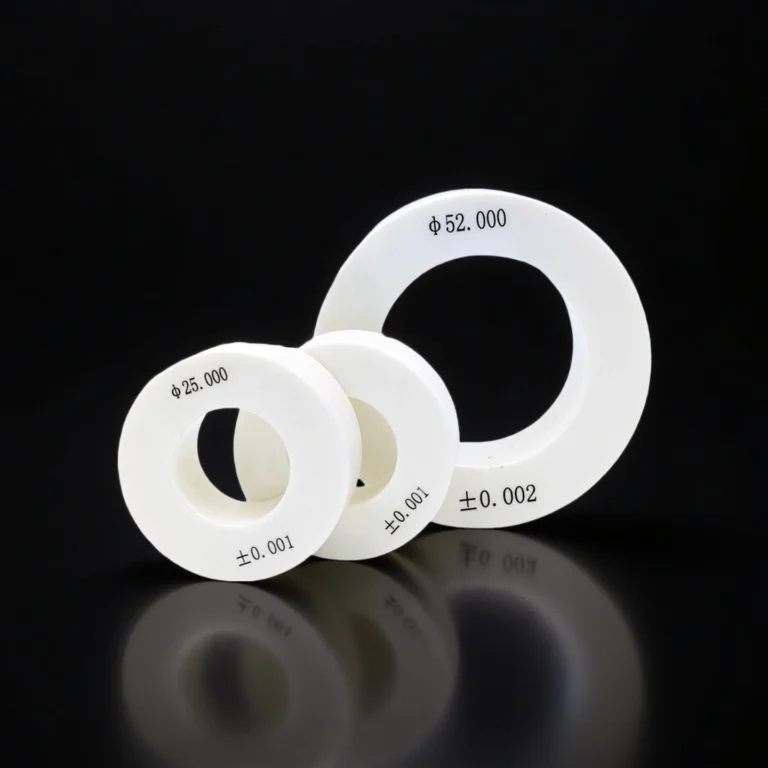

Alumina Ceramic Pin Gauge Specifications

| Alumina Ceramic Pin Gauge | ||||

| Item No. | Size(mm) | Set interval | Accuracy(H) | Weight(g) |

| AT-CMT-1001 | 0.30-0.699 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 50 |

| AT-CMT-1002 | 0.70-0.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 60 |

| AT-CMT-1003 | 1.0-2.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 70 |

| AT-CMT-1004 | 3.0-3.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 80 |

| AT-CMT-1005 | 4.0-4.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 90 |

| AT-CMT-1006 | 5.0-5.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 100 |

| AT-CMT-1007 | 6.0-6.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 110 |

| AT-CMT-1008 | 7.0-7.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 120 |

| AT-CMT-1009 | 8.0-8.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 130 |

| AT-CMT-1010 | 9.0-9.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 140 |

| AT-CMT-1011 | 10.0-10.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 145 |

| AT-CMT-1012 | 11.0-11.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 150 |

| AT-CMT-1013 | 12.0-12.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 155 |

| AT-CMT-1014 | 13.0-13.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 160 |

| AT-CMT-1015 | 14.0-14.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 165 |

| AT-CMT-1016 | 15.0-15.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 170 |

| AT-CMT-1017 | 16.0-16.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 175 |

| AT-CMT-1018 | 17.0-17.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 180 |

| AT-CMT-1019 | 18.0-18.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 185 |

| AT-CMT-1020 | 20.2-40mm | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 190 |

Alumina Ceramic Pin Gauge Packaging

- Each alumina ceramic pin gauge is stored in a protective sleeve or tube to avoid impact during transport.