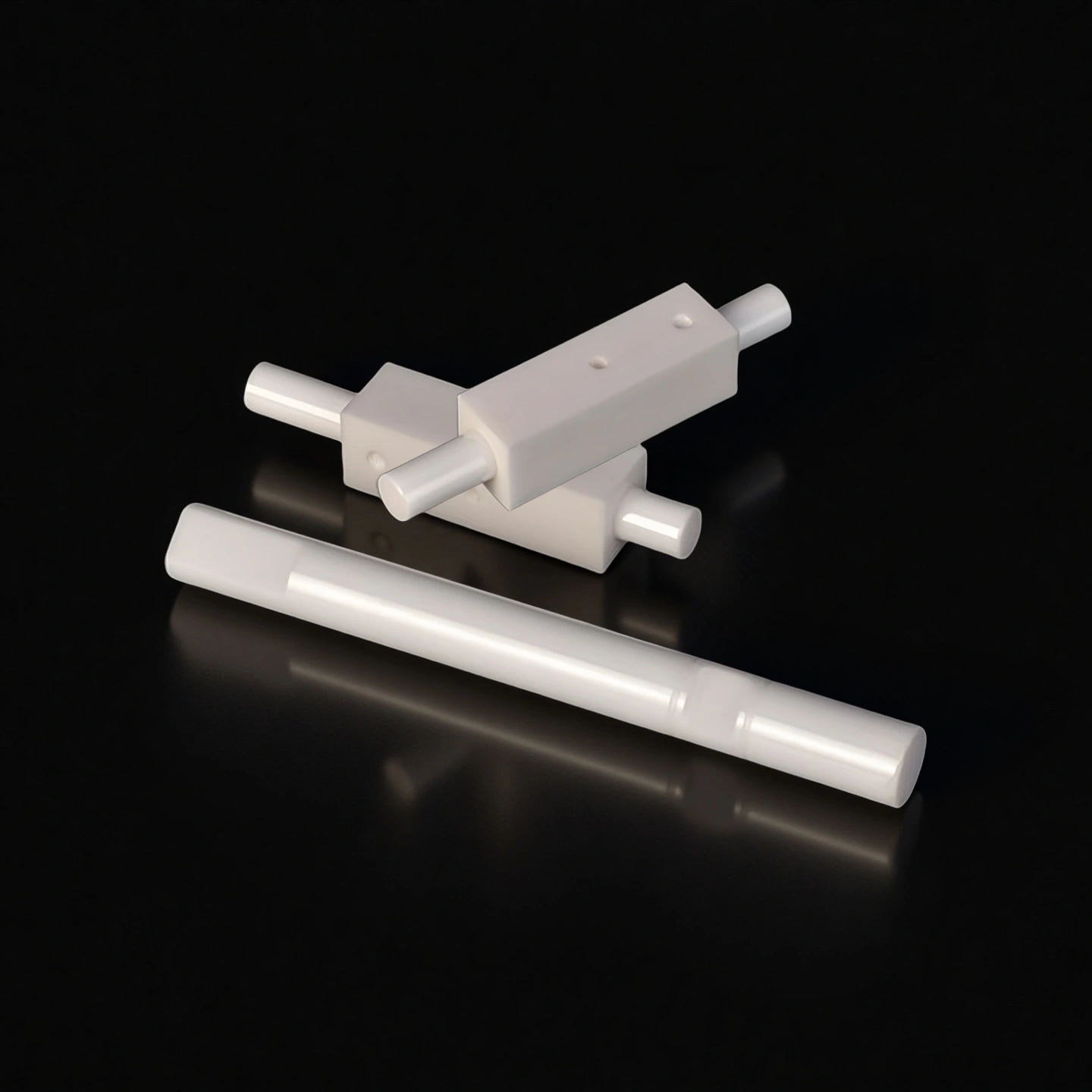

Zirconia plungers are advanced ceramic components engineered for precision liquid dosing systems, ensuring dimensional stability, high wear resistance, and compatibility with corrosive fluids. Suitable for use in metering pumps, fluid delivery devices, and high-pressure syringe pumps.

Zirconia Plunger Benefits

- Consistent Dimensional Stability: Resistance to deformation under pressure and temperature ensures consistent metered dosing.

- Superior Wear Life: Hardness (HV > 1200) and low porosity reduce maintenance replacement costs over time.

- Chemical Resistance: Inert response to acids, bases, and solvents, allowing use in complex chemical dosing scenarios.

- Surface Finishing: Ra < 0.2µm ensures minimized abrasion against mating components and improves seal longevity.

- High Thermal Shock Reliability: Tolerance to sudden thermal changes, ideal for controlled-temperature fluid systems.

Zirconia Plunger Specifications

| Zirconia Plunger | ||||

| Item NO. | Diameter(mm) | Surface Roughness of Rod(μm) | Surface Roughness of Slope(μm) | Roundness(mm) |

| AT-YHG-ZS001 | 2.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS002 | 3.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS003 | 4.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS004 | 5.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS005 | 6.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS006 | 7.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS007 | 8.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS008 | 9.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS009 | 10.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS010 | 11.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS011 | 12.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS012 | 13.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS013 | 14.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS014 | 15.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS015 | 16.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS016 | 17.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS017 | 18.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS018 | 19.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS019 | 20.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS020 | 21.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS021 | 22.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS022 | 23.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS023 | 24.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS024 | 25.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS025 | 26.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS026 | 27.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS027 | 28.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS028 | 29.00±0.001 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS029 | 30.00±0.002 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS030 | 31.00±0.002 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS031 | 32.00±0.002 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS032 | 33.00±0.002 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS033 | 34.00±0.002 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS034 | 35.00±0.002 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS035 | 36.00±0.002 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS036 | 37.00±0.002 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS037 | 38.00±0.002 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS038 | 39.00±0.002 | Ra0.1 | Ra0.2 | ≤0.002 |

| AT-YHG-ZS039 | 40.00±0.002 | Ra0.1 | Ra0.2 | ≤0.002 |

Packing:

- Packed in anti-static ESD bags

- With foam separators in Export-grade rigid cartons