Silicon nitride ball valve is a quarter-turn valve that uses a Si₃N₄ ceramic ball running against a precision-lapped seat to start, stop, or modulate flow, especially in abrasive and/or corrosive media. It is supplied in round-port trims for on/off isolation and V-port trims (e.g., 60°/90°) for equal-percentage control. The ceramic trim keeps a stable sealing band under solids, chemical attack, and thermal cycling, where metal balls and seats wear or gall.

Silicon Nitride Ball Valve Benefits

-

V-port equal-percentage control maintains a stable flow coefficient (Cv) even at small openings, enabling precise slurry dosing and proportional control in variable-density media. The V-notch design ensures linear response across a wide range of operating pressures, minimizing oscillation in closed-loop systems.

-

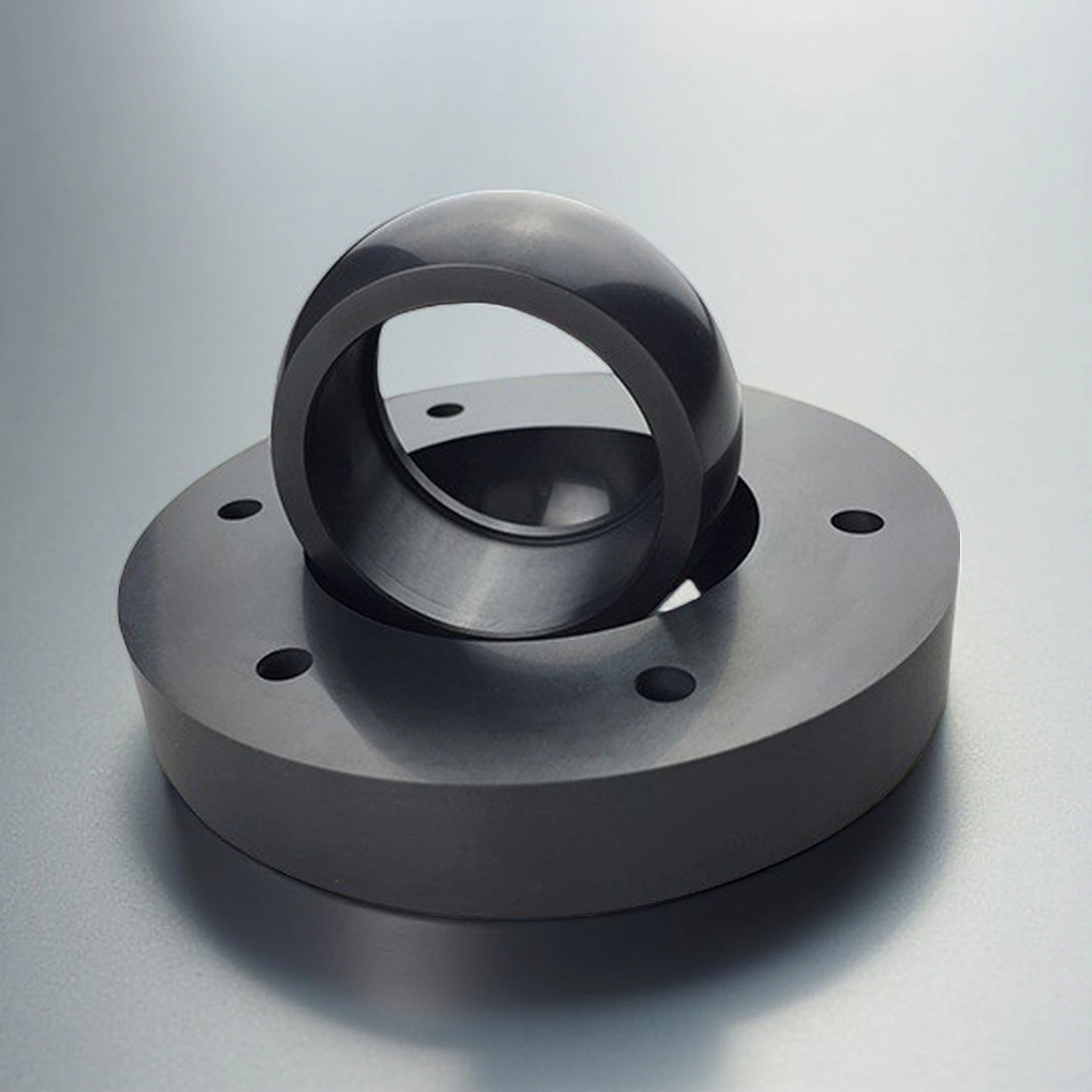

Si₃N₄ ball + lapped ceramic seat preserves the sealing band under long-term abrasion. The ball roundness (≤0.03 mm) and seat surface finish (Ra ≤ 0.4 µm) are manufactured to ISO 3290-2 standards, preventing leakage drift even after millions of opening cycles in abrasive slurry applications.

-

Low CTE pairing between the silicon nitride ball and the ceramic seat minimizes dimensional changes across temperature variations from 20 °C to 120 °C. This compatibility keeps the sealing interface stable in batch or start-stop duties, reducing maintenance caused by thermal fatigue or expansion mismatch.

-

Anti-chipping geometry with port-edge relief mitigates particle impact and prevents micro-cracks during fast actuation. This design feature extends the service life of the silicon nitride ball valve in heavy-solids environments such as hydrometallurgy and pulp-stock transfer systems.

-

Actuator-ready ISO 5211 interface simplifies integration with pneumatic or electric actuators. The standardized mounting pad allows quick retrofit and precise positioner feedback without adapter brackets, reducing setup time and ensuring consistent torque alignment during automation upgrades.

Silicon Nitride Ceramic Ball Valve Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Si3N4 Ball Valve Specifications

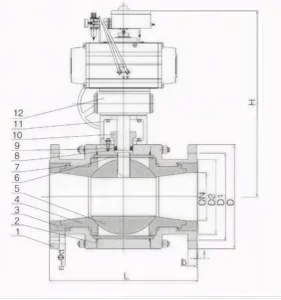

Type 1: Silicon Nitride Ceramic Ball Valve O-Type

| Silicon Nitride Ceramic Ball Valve O-Type | ||||||||

| Item No. | DN | PH (Mpa) | D | D1 | D2 | C | H | n-d |

| AT-SIN-QF001 | 15 | 1.6 | 130 | 95 | 45 | 14 | 180 | 4-∅14 |

| AT-SIN-QF002 | 20 | 1.6 | 140 | 105 | 55 | 16 | 190 | 4-∅14 |

| AT-SIN-QF003 | 25 | 1.6 | 150 | 115 | 65 | 16 | 220 | 4-∅14 |

| AT-SIN-QF004 | 32 | 1.6 | 165 | 135 | 75 | 18 | 235 | 4-∅18 |

| AT-SIN-QF005 | 40 | 1.6 | 180 | 145 | 85 | 18 | 255 | 4-∅18 |

| AT-SIN-QF006 | 50 | 1.6 | 203 | 160 | 100 | 20 | 270 | 4-∅18 |

| AT-SIN-QF007 | 65 | 1.6 | 220 | 180 | 120 | 20 | 310 | 4-∅18 |

| AT-SIN-QF008 | 80 | 1.6 | 250 | 195 | 135 | 20 | 370 | 8-∅18 |

| AT-SIN-QF009 | 100 | 1.6 | 280 | 215 | 155 | 22 | 430 | 8-∅18 |

| AT-SIN-QF010 | 125 | 1.6 | 320 | 245 | 185 | 22 | 510 | 8-∅18 |

| AT-SIN-QF011 | 150 | 1.6 | 394 | 280 | 210 | 24 | 590 | 8-∅23 |

| AT-SIN-QF012 | 200 | 1.6 | 457 | 335 | 265 | 24 | 750 | 8-∅23 |

| AT-SIN-QF013 | 250 | 1.6 | 533 | 506 | 320 | 26 | 850 | 12-∅23 |

| AT-SIN-QF014 | 300 | 1.6 | 610 | 460 | 375 | 30 | 920 | 12-∅25 |

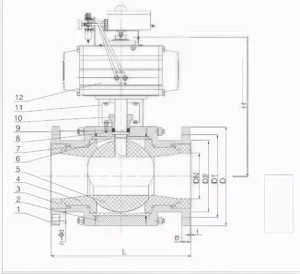

Type 2: Silicon Nitride Ball Valve V Type

| Silicon Nitride Ball Valve V Type | ||||||||||

| Item NO. | DN | NPS | H | L | D | D1 | D2 | n-d | b | f |

| AT-SIN-QF015 | 15 | 1 2" | 170 | 108 | 90 | 60.3 | 34.9 | 4-M12 | 11.6 | 2 |

| AT-SIN-QF016 | 20 | 3 /4" | 180 | 117 | 100 | 69.9 | 42.9 | 4-M12 | 13.2 | 2 |

| AT-SIN-QF017 | 25 | 1" | 185 | 127 | 110 | 79.4 | 50.8 | 4-M12 | 14.7 | 2 |

| AT-SIN-QF018 | 32 | 1-1/4" | 220 | 140 | 115 | 88.9 | 63.5 | 4-M12 | 16.3 | 2 |

| AT-SIN-QF019 | 40 | 1-1/2" | 230 | 165 | 125 | 98.4 | 73 | 4-M12 | 17.9 | 2 |

| AT-SIN-QF020 | 50 | 2" | 247 | 178 | 150 | 120.7 | 92.1 | 4-M16 | 19.5 | 2 |

| AT-SIN-QF021 | 65 | 2-1/2" | 270 | 190 | 180 | 139.7 | 104.8 | 4-M16 | 22.7 | 2 |

| AT-SIN-QF022 | 80 | 3" | 310 | 203 | 190 | 152.4 | 127 | 4-M16 | 24.3 | 2 |

| AT-SIN-QF023 | 100 | 4" | 355 | 229 | 230 | 190.5 | 139.7 | 4-M16 | 24.3 | 2 |

| AT-SIN-QF024 | 125 | 5" | 430 | 356 | 255 | 215.9 | 157.2 | 4-M20 | 24.3 | 2 |

| AT-SIN-QF025 | 150 | 6" | 490 | 394 | 280 | 241.3 | 185.7 | 4-M21 | 25.9 | 2 |

| AT-SIN-QF026 | 200 | 8" | 590 | 457 | 345 | 298.5 | 215.9 | 4-M22 | 29 | 2 |

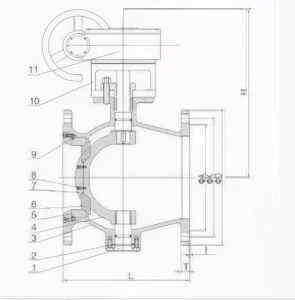

Type 3: Silicon Nitride Ball Valve Eccentric

| Silicon Nitride Ball Valve Eccentric | ||||||||||

| Item NO. | PN(Mpa) | DN(mm) | H | L | D | D1 | D2 | n-d | C | F |

| AT-SIN-QF027 | 1.6 | 50 | 230 | 124 | 165 | 125 | 100 | 4-∅18 | 16 | 3 |

| AT-SIN-QF028 | 1.6 | 65 | 237 | 145 | 185 | 145 | 120 | 4-∅18 | 18 | 3 |

| AT-SIN-QF029 | 1.6 | 80 | 260 | 165 | 200 | 160 | 135 | 8-∅18 | 20 | 3 |

| AT-SIN-QF030 | 1.6 | 100 | 270 | 194 | 220 | 180 | 156 | 8-∅18 | 20 | 3 |

| AT-SIN-QF031 | 1.6 | 125 | 320 | 210 | 250 | 210 | 185 | 8-∅22 | 22 | 3 |

| AT-SIN-QF032 | 1.6 | 150 | 340 | 229 | 285 | 240 | 211 | 8-∅22 | 26 | 3 |

| AT-SIN-QF033 | 1.6 | 200 | 390 | 243 | 340 | 295 | 265 | 8-∅23 | 26 | 3 |

| AT-SIN-QF034 | 1.6 | 250 | 420 | 297 | 405 | 355 | 319 | 8-∅26 | 30 | 3 |

| AT-SIN-QF035 | 1.6 | 300 | 510 | 338 | 460 | 410 | 375 | 8-∅26 | 30 | 4 |

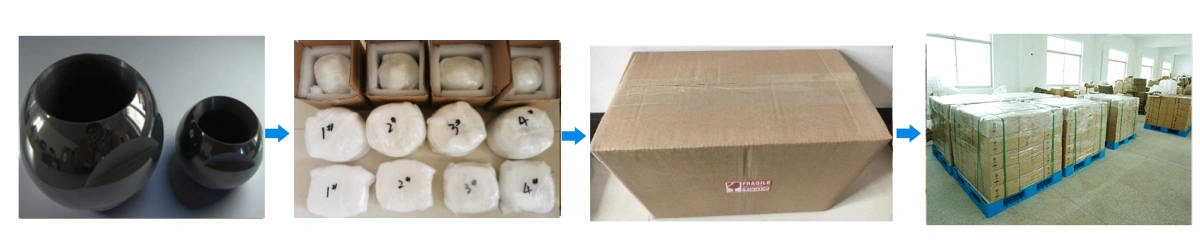

Si3N4 Ball Valve Packaging

- Ball/seat contact faces protected with soft caps; valve ports sealed; unit placed in foam cradle within a double-wall carton; palletized for mid/large DN.