Engineers often face demanding requirements when sourcing ceramic tubes. Minor flaws in selection may lead to costly downtime. Careful supplier evaluation ensures reliable performance.

To choose an alumina ceramic tube supplier, align evaluation with each application. Verify risks, demand engineered solutions, and test purity, tolerances, dielectric strength, thermal cycling, leak rate, and documentation.

Selecting the right partner requires more than price. The following sections provide application-specific supplier checklists, helping procurement teams minimize failures and optimize lifecycle costs.

Alumina Ceramic Tubes for Thermocouple Protection

Thermocouple protection tubes are exposed to high heat, rapid cycling, and sealing challenges. Failures in these tubes lead directly to inaccurate readings and costly downtime. A supplier’s ability to engineer and verify designs is critical for success.

Failure Modes and Process Risks

Cracking in thermocouple tubes usually starts at stress points. Such cracks propagate quickly under repeated cycles. Failures compromise both data accuracy and operational stability.

Unexpected leak paths often arise during sealing. Engineers must account for gas infiltration. This can accelerate corrosion and further damage sensors.

In many cases, the risks can be grouped as:

- Thermal shock cracks disrupting reliability

- Seal penetration causing data drift

- Structural stress reducing tube lifespan

Supplier Engineering Solutions

Engineered features like closed-end forming address sealing risks. These design changes create stronger interfaces. They also reduce crack initiation zones.

Chamfered edges improve seal seating. Combined with material grades designed for rapid heating and cooling, suppliers deliver tubes with extended durability.

For procurement, this means prioritizing:

- Closed-end forming for seal integrity

- Edge chamfers for proper seating

- Shock-resistant grades for thermal stability

Selection & Verification Dimensions

Suppliers must prove capability through inspection and testing. Straightness and seal fit tolerance are basic metrics. Leak tests confirm atmosphere isolation.

Thermal cycling simulations show how tubes perform under real-world furnace use. Certified documentation closes the loop. Only vendors with these reports should be considered.

| Verification Dimension | Required Method | Benchmark Values |

|---|---|---|

| Straightness | Optical check | <0.5 mm deviation / 300 mm |

| Leak rate | Helium test | ≤1×10⁻⁶ mbar·L/s |

| Thermal cycle | 20–1000 °C cycles | No visible cracks after 50 cycles |

Alumina Ceramic Process Tubes for Laboratory Tube Furnaces

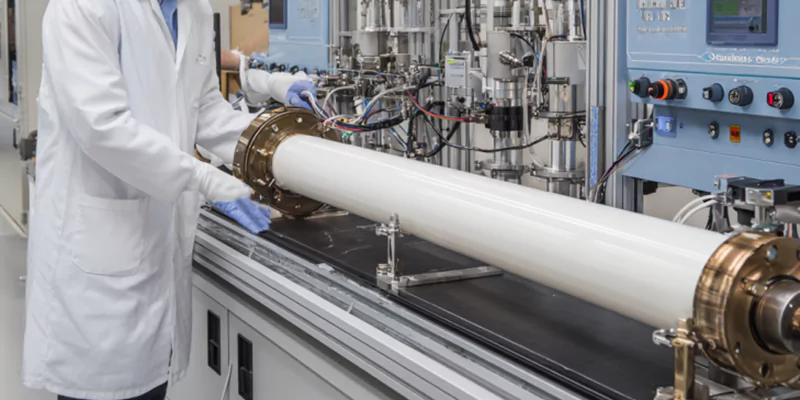

Laboratory tube furnaces1 require alumina ceramic tubes that maintain atmosphere integrity and geometric precision. Small deviations can invalidate experiments and waste resources. A capable supplier ensures sealing quality and consistency.

Fitment and Atmosphere Integrity Risks

When seals fail, furnaces lose controlled conditions. Even small leaks allow unwanted gases in. This disrupts reactions and test repeatability.

Misalignment between furnace fittings and tube ends also introduces stress. These stresses can reduce operational life. If overlooked, frequent replacements occur.

From this perspective, risks manifest as:

- Seal leakage degrading experiments

- Geometric misalignment increasing stress

- Atmosphere instability reducing data validity

Design and Manufacturing Solutions

End geometry control is central to reliable sealing. Proper flatness ensures full contact. Consistency reduces variance between batches.

Surface roughness at sealing faces improves sealing strength. By reducing micro gaps, vendors limit leak paths. Suppliers should also document process control.

Thus, priority should be given to:

- Flat end geometry for sealing accuracy

- Controlled roughness for reliable fit

- Batch consistency to avoid variance

Selection & Verification Dimensions

Procurement teams should demand leakage rate data. Dimensional tolerance sheets support compatibility. Thermal validation simulates real operating profiles.

With these data points, buyers compare suppliers quantitatively. Reliability depends on measurable values rather than assumptions.

| Verification Dimension | Required Method | Benchmark Values |

|---|---|---|

| Leakage rate | Pressure decay test | ≤0.02% per hour |

| End roughness | Surface profilometer | Ra ≤0.8 µm |

| Thermal check | 20–1200 °C cycle | No deformation after 30 cycles |

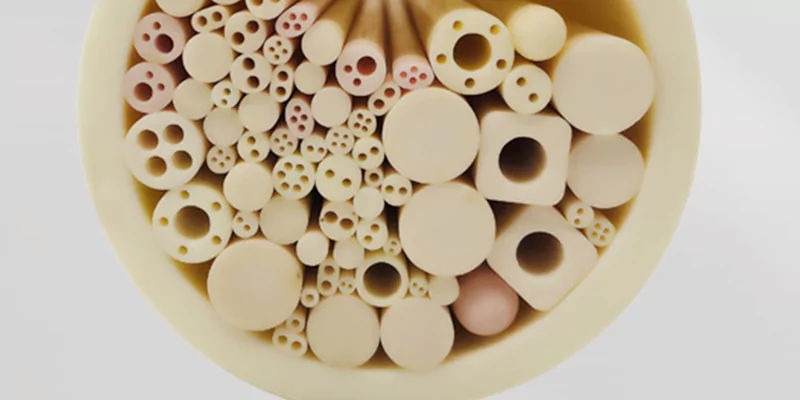

Multi-Bore Alumina Ceramic Tubes for Electrical Feedthroughs

Electrical feedthrough2 applications require high dielectric strength and cleanliness. Impurities or dimensional variation can result in catastrophic arcing. Suppliers must control bore spacing, wall uniformity, and contamination.

Dielectric and Cleanliness Risks

Voltage stress concentrates near irregularities. Contamination accelerates breakdown. Failures occur suddenly and damage connected equipment.

Cleanliness matters at the ionic level. Even residual salts lower resistance. Over time, this leads to unpredictable failures.

It is therefore useful to consider:

- Dielectric breakdown risk from geometry

- Ion contamination risk lowering resistance

- Sudden failure risk increasing repair costs

Precision and Process Controls

Accurate bore spacing of multi-bore alumina tubes distributes fields evenly. Uniform wall thickness avoids weak points. Clean sintering removes ion residues.

When combined, these controls ensure reliability. Suppliers who measure and report each step provide stronger assurance.

Key areas to check include:

- Bore spacing accuracy to manage electric fields

- Wall thickness uniformity for mechanical balance

- Clean sintering for dielectric stability

Selection & Verification Dimensions

Testing should include dielectric breakdown voltage3. Surface resistance provides long-term indicators. Cleanliness can be proven by reports of ionic analysis. Suppliers that fail to provide measurable data may hide process variability. Quantified metrics are procurement’s safeguard.

| Verification Dimension | Required Method | Benchmark Values |

|---|---|---|

| Dielectric strength | ASTM D149 | 10–12 kV/mm |

| Surface resistance | Megohm test | ≥10¹² Ω |

| Cleanliness | Ion chromatography | <50 ppm Na⁺/K⁺ |

Wear-Resistant Alumina Ceramic Tubes for Powder/Slurry Transport

In powder and slurry transport, alumina tubes face constant erosion. Material selection and surface treatments directly impact service life. Procurement must confirm density, hardness, and wear testing.

Erosion and Blockage Risks

Abrasive media gradually thins the tube wall. Eventually, this leads to leaks. Throughput and reliability decline.

Deposits and scaling create blockages. These slow flow and increase energy use. Together, erosion and scaling reduce efficiency.

Practical patterns emerge as:

- Abrasive erosion reducing wall thickness

- Scaling and clogging slowing flow

- Energy inefficiency from blockages

Microstructure and Surface Engineering

High bulk density correlates with resistance. Smaller grains increase hardness. Smooth finishes reduce deposition.

Suppliers controlling sintering and polishing deliver superior tubes. Microstructure reports confirm performance. These reports should be required.

Thus, focus is on:

- High density improving wear life

- Fine grain size boosting toughness

- Smooth finishes lowering deposition

Selection & Verification Dimensions

Procurement must ask for hardness data. Density should be measured to ASTM standards. Slurry wear testing validates real-life durability.

Numbers matter here more than claims. Buyers who ignore them face higher maintenance costs.

| Verification Dimension | Required Method | Benchmark Values |

|---|---|---|

| Bulk density | ASTM C373 | ≥3.8 g/cm³ |

| Hardness | Vickers | ≥15 GPa |

| Slurry wear rate | ASTM G65 slurry test | <1.5 mm³ loss/hr |

High-Temperature Gas Sampling and Probes

Gas probes are stressed by rapid temperature swings and contamination. Tubes must resist shock while providing clean sampling. Suppliers must optimize closed ends and material grades.

Thermal Shock and Contamination Risks

Sudden cooling causes surface cracks. Expansion mismatch accelerates failures. Sampling quality decreases.

Deposited particles clog probe ends. Dust and slag reduce reliability. Regular failures disrupt testing.

These risks group as:

- Rapid thermal shock creating cracks

- Expansion mismatch accelerating breakage

- Ash deposition blocking samples

Probe-End Design and Material Choices

Wall thickness must balance durability and responsiveness. Smooth radii reduce stress. Grade choice must suit gas chemistry.

Suppliers skilled in geometry optimization and material selection extend tube lifetime. Validations are critical.

Procurement focus should be on:

- Optimized wall thickness balancing strength and speed

- Smooth radii lowering stress risks

- Grade matching ensuring chemical fit

Selection & Verification Dimensions

Testing must simulate rapid heating and cooling. Cleanliness validation confirms sampling accuracy. End geometry should be inspected under magnification.

Quantitative testing reduces risk. Without this, probe life is unpredictable.

| Verification Dimension | Required Method | Benchmark Values |

|---|---|---|

| Thermal cycling | 20–1000 °C cycle | No cracks after 30 cycles |

| Cleanliness | Particle analysis | <10 µg/cm² residue |

| End geometry | Optical check | Smooth radius ≥1.5 mm |

Reactor Liners and Catalyst Supports Using Alumina Tubes

Reactors require stable liners and catalyst supports. Alumina tubes must resist corrosion and avoid deactivating catalysts. Supplier chemistry control ensures success.

Chemical Attack and Deactivation Risks

Acidic or basic gases corrode alumina. This weakens liners. Process stability declines.

Impurities deactivate catalysts. Even small amounts reduce output. Losses accumulate quickly.

The recurring threats are:

- Corrosive attack reducing strength

- Impurities poisoning catalysts

- Performance decline cutting output

Grade and Surface Finish Controls

Purity levels affect corrosion resistance. Low inclusions improve compatibility. Surface finish stabilizes catalyst beds.

Suppliers must prove grade and finish through data. Polished surfaces reduce risks. Certificates add reliability.

From an evaluation standpoint:

- High purity grades for corrosion defense

- Low inclusion counts supporting compatibility

- Polished finishes for stable catalyst support

Selection & Verification Dimensions

Suppliers should present corrosion test results. Porosity checks confirm stability. Compatibility evaluations prove integration with catalyst beds.

Reports must be quantified and verified. This provides assurance of reactor uptime.

| Verification Dimension | Required Method | Benchmark Values |

|---|---|---|

| Corrosion resistance | Acid/base soak | <0.1% weight loss / 24h |

| Porosity | Mercury intrusion | ≤2% open porosity |

| Compatibility | Catalyst support test | No reaction with standard pellets |

Insulating Spacers and Bobbins in Vacuum Furnaces

Vacuum furnaces demand insulation that resists breakdown and outgassing. Alumina purity and pre-degassing are key. Suppliers must validate performance.

Dielectric Breakdown and Outgassing Risks

At high voltages, impure tubes break down. This damages coils. System reliability suffers.

Outgassing creates contamination. Residual gases interfere with furnace operation. Losses are significant.

The main risks to track are:

- Dielectric failure at high fields

- Residual gas release contaminating furnaces

- System instability from breakdown

Material Purity and Degassing Protocols

Low-alkali alumina reduces dielectric risks. Pre-degassing stabilizes materials. These steps improve furnace performance.

Suppliers with documented degassing protocols offer assurance. Certifications validate stability. Data closes the loop.

Procurement should value:

- Low-alkali grades preventing breakdown

- Pre-degassing stabilizing materials

- Certifications confirming stability

Selection & Verification Dimensions

Testing includes dielectric and vacuum bake-outs. Residual gas analysis verifies outgassing control. Certified reports are required.

Procurement should not rely on claims. Numbers are essential to confidence.

| Verification Dimension | Required Method | Benchmark Values |

|---|---|---|

| Dielectric strength | ASTM D149 | ≥10 kV/mm |

| Vacuum bake-out | 10⁻⁵ mbar / 12h | Stable pressure |

| Residual gases | Mass spectrometry | <1 ppm hydrocarbons |

Supplier Qualification Checklist for Alumina Ceramic Tubes in 2025

Suppliers vary widely in quality and reliability. A qualification checklist standardizes evaluation. It covers capabilities, certifications, and logistics.

Capability & Process Control Evidence

Manufacturing methods define product reliability. Isostatic pressing and sintering curves provide control. Evidence supports supplier claims.

Procurement teams must verify each capability. Without documentation, claims remain assumptions. Only proven suppliers qualify.

Quality & Certification Evidence

Lot traceability supports accountability. Batch certificates validate quality. Recognized certifications increase trust.

When combined, these factors reduce risk. Procurement gains confidence in supplier selection.

Logistics & Continuity Evidence

Dual production lines mitigate disruption. Safety stock ensures availability. Service level agreements formalize delivery.

Suppliers lacking redundancy pose risk. Procurement must demand continuity proof.

Cost and Lead-Time Planning for Alumina Ceramic Tube Sourcing

Procurement success balances cost, time, and reliability. Alumina tubes vary in grade and complexity. Planning requires clarity.

Cost Drivers Engineers Should Quantify

Purity directly influences cost. Forming and finishing also add expense. Testing provides assurance but adds cost.

Engineers should model total spend. This supports realistic sourcing strategies. Decisions must account for all drivers.

Lead-Time Profiles and Order Strategies

Stock tubes ship faster. Custom parts require weeks. Batch sizes affect timelines.

Procurement should balance flexibility and continuity. This reduces delays.

Trade-offs and Total Cost of Ownership

Low-grade tubes cut costs early. Failures increase lifecycle expense. True cost emerges over time.

Procurement must use TCO frameworks. This aligns short-term and long-term goals.

Incoming Inspection and Reliability Testing for Alumina Ceramic Tubes

Receiving inspections prevent hidden failures. Measurable tests reduce early-life risks. Procurement must enforce standards.

Dimensional and Visual Checks

Outer and inner diameters show accuracy. Straightness prevents fit issues. Surface flaws must be excluded.

Visual checks alone are insufficient. Measurements confirm quality. Combined inspection ensures reliability.

Thermal and Mechanical Tests

Thermal cycling validates endurance. Flexural and hardness tests confirm strength. Failures are exposed early.

Procurement gains assurance from these methods. Long-term reliability improves.

Documentation and NCR Handling

Certificates confirm conformance. PPAP adds rigor. Non-conformance handling closes the loop.

Procurement must require clear documentation. This strengthens supplier accountability.

Conclusion

Supplier evaluation by application ensures reliability and cost efficiency.

Navigating supplier decisions for alumina ceramic tubes requires measurable criteria. Leverage ADCERAX engineering support, factory-direct supply, and small-batch customization for a reliable sourcing partnership.

FAQ (Frequently Asked Questions)

Q1: What dielectric strength can alumina ceramic tubes maintain in feedthroughs?

Alumina tubes typically maintain dielectric strength around 10–12 kV/mm at room temperature. This ensures stable feedthrough insulation when purity and cleanliness are controlled.

Q2: How should procurement teams balance cost and lead time when choosing a supplier?

Teams should compare stock versus custom availability. Stock reduces delays, while custom orders allow application-specific designs. Lifecycle cost analysis should guide final choices.

Q3: What incoming inspection steps are essential for alumina ceramic tubes?

Dimensional checks, thermal cycle testing, and hardness evaluation are essential. Documented non-conformance handling adds assurance of consistent quality.

Q4: How do alumina ceramic tubes compare with quartz tubes in high-temperature use?

Alumina withstands continuous service up to 1600 °C, while quartz softens above 1100–1200 °C. This makes alumina the better choice for furnace liners and thermocouple sheaths.

References:

-

Discover how tube furnaces work and their applications in labs to better understand their importance and proper usage. ↩

-

Learn about electrical feedthroughs, their uses, and why high dielectric strength and cleanliness are crucial for reliable performance. ↩

-

Understanding dielectric breakdown voltage is crucial for ensuring the safety and reliability of electrical systems. ↩