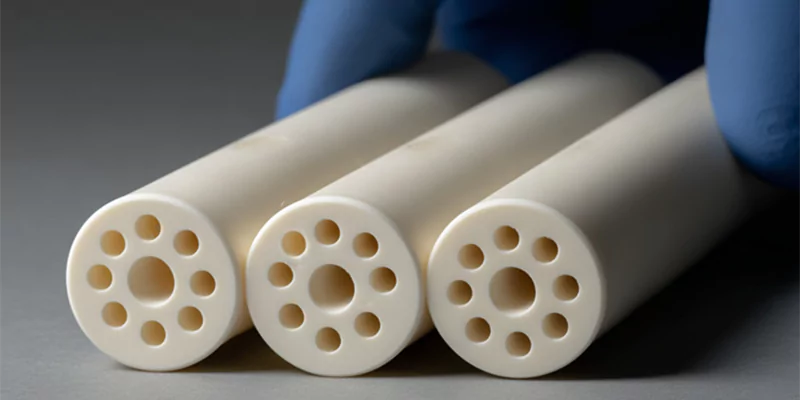

Uniform performance in compact high-temperature systems demands components that can withstand stress. Engineers face challenges balancing gas flow precision with thermal stability in confined spaces. The geometry of a 9-hole alumina ceramic tube directly addresses this engineering challenge.

9-hole alumina ceramic tubes provide uniform gas distribution and enhance thermal reliability in compact systems by reducing stress concentration and stabilizing performance under heat.

Reliable results in combustion, sensing, and micro-reactor applications all depend on how design features translate into performance. The following sections break down structural, thermal, and application-driven evidence that explains the contribution of 9-hole alumina ceramic tubes.

Structural Characteristics of 9-Hole Alumina Ceramic Tubes

Structural characteristics define how multi-bore alumina ceramics support engineering applications. A 9-hole tube maximizes usable space while balancing wall strength and distribution pathways. These features form the basis for gas distribution and thermal reliability.

Multi-Channel Geometry and Space Utilization

Multi-channel geometry provides engineers with the ability to integrate several functional pathways into a compact form. Two sentences describe how this enhances design freedom and supports system miniaturization. One final sentence emphasizes efficiency in compact assemblies.

To better illustrate how geometry affects utilization, engineers note the following aspects:

- Channel density supports compact design

- Multiple functions combine within one tube

- Reduced footprint improves integration options

Wall Thickness and Thermal Pathways

Wall thickness influences both strength and thermal response in alumina tubes. Two sentences explain how balanced thickness prevents mechanical failures and aids heat dissipation. A concluding sentence links wall design with long-term performance.

| Parameter | Design Impact | Reliability Outcome |

|---|---|---|

| Thin walls | Promote faster heat transfer | Higher risk of fracture |

| Balanced walls | Control expansion stresses | Improved service life |

| Thick walls | Increase durability | Reduced thermal efficiency |

Distribution Uniformity Across Channels

Distribution uniformity ensures that each bore delivers predictable performance. Two sentences highlight its role in maintaining equal flow rates and stability in combustion. A final sentence stresses its importance for compact gas systems.

From observed performance, uniform distribution contributes through:

- Stable velocity across all channels

- Equalized pressure balance

- Reduced adjustment needs during operation

Mechanisms Supporting Gas Distribution Efficiency

Gas distribution efficiency is achieved when structural design translates into controlled flow behavior. A 9-hole alumina tube stabilizes flow conditions while mitigating risks of imbalance. This section explains the specific mechanisms.

Flow Separation and Mixing Effects

Flow separation occurs naturally in multi-bore channels, helping avoid cross-interference. Two sentences explain how this prevents undesired mixing and maintains precise gas ratios. One closing sentence ties these effects to combustion control.

| Mechanism | Structural Basis | Performance Effect |

|---|---|---|

| Separation | Individual bores | Prevents flow interference |

| Controlled mixing | Geometry-driven | Ensures uniform distribution |

| Reduced turbulence | Smooth bore walls | Enhances flow predictability |

Pressure Balance Across Nine Channels

Pressure balance ensures that all nine bores operate under similar conditions. Two sentences explain how bore symmetry reduces variations and prevents instability. A final sentence confirms its contribution to reliable system design.

Key aspects of pressure control can be summarized as:

- Equal bore size maintains consistency

- Symmetrical geometry stabilizes gradients

- Uniform pressure reduces component stress

Reduced Leakage and Bypass Risks

Smaller bore diameters limit leakage opportunities in compact tubes. Two sentences explain how this decreases bypass flow and ensures sealing efficiency. One closing sentence links this mechanism to better flow regulation.

| Risk Factor | Effect in Fewer Bores | Effect in 9-Hole Tube |

|---|---|---|

| Leakage | Higher due to larger gaps | Lower due to smaller bores |

| Bypass flow | More likely in wide channels | Less likely with dense layout |

| Sealing | Difficult in large diameters | Easier in compact channels |

Mechanisms Enhancing Thermal Reliability

Thermal reliability emerges when structural elements distribute heat loads evenly. A 9-hole alumina tube lowers localized stress and supports repeated cycles. This section outlines the main mechanisms.

Heat Dissipation Through Distributed Walls

Distributed walls conduct heat more evenly across the ceramic. Two sentences describe how this prevents hot spots and prolongs tube life. A closing sentence links dissipation to improved stability.

Important points from thermal distribution include:

- Even heat spreading prevents hot spots

- Multiple walls moderate thermal loads

- Durability increases under cycling stress

Lower Localized Thermal Stress

Stress reduction results from distributing loads across several walls. Two sentences explain how this minimizes fracture initiation and supports longer service. A final sentence highlights its importance in fluctuating operations.

| Stress Factor | In Fewer Bores | In 9-Hole Tube |

|---|---|---|

| Localized heating | Concentrated stress zones | Dispersed loads |

| Fracture initiation | High probability | Reduced probability |

| Reliability | Limited under cycles | Improved across cycles |

Stable Performance Under Cyclic Heating

Cyclic heating often reduces ceramic reliability over time. Two sentences describe how nine channels moderate expansion forces. One closing sentence confirms stable performance under thermal cycling.

From tested results, cyclic stability is achieved through:

- Distributed expansion minimizes stress

- Repeated cycles show reduced cracking

- Operational lifespan is significantly extended

Application in High-Temperature Combustion Systems

Combustion systems demand predictable flames and durability in compact units. 9-hole tubes contribute by balancing gas distribution with thermal stability. This section explains how.

Role in Compact Burner Arrays

Burner arrays benefit from multiple bores carrying uniform gas streams. Two sentences explain how this enhances flame consistency and thermal efficiency. A final sentence stresses its value for compact combustion setups.

| Parameter | 2-Hole Tubes | 9-Hole Tubes |

|---|---|---|

| Gas uniformity | Limited | High |

| Flame stability | Variable | Stable |

| Durability | Moderate | Extended |

Contribution to Stable Flame Profiles

Stable flame profiles emerge when gas flow is evenly delivered. Two sentences explain how this reduces incomplete combustion and improves efficiency. One closing sentence emphasizes emissions control benefits.

Flame profile improvements can be grouped into:

- Balanced flame geometry

- Reduced incomplete combustion

- Lower emissions output

Durability Under Continuous Firing Cycles

Continuous use tests ceramics with extreme cycling. Two sentences highlight alumina’s endurance and how nine bores resist crack growth. A closing sentence confirms extended operating life.

| Property | Conventional Tubes | 9-Hole Tubes |

|---|---|---|

| Cycle resistance | Moderate | High |

| Crack risk | Elevated | Reduced |

| Operational lifespan | Shorter | Longer |

Application in Sensor and Probe Protection

Compact sensors require thermal and electrical insulation. Multi-bore alumina tubes deliver these protections. This section describes the benefits.

Multi-Channel Isolation for Thermocouples

Each bore isolates wires from interference. Two sentences explain how this ensures reliable readings and reduces noise. A final sentence connects isolation with measurement accuracy.

Key contributions from isolation design include:

- Independent sensor pathways

- Reduced electrical cross-talk

- Stable readings under heat

Electrical Insulation for Compact Instrumentation

Alumina resists conductivity even under high heat. Two sentences explain how this secures sensitive circuits and enables multiple probes. One closing sentence stresses compact equipment reliability.

| Aspect | Performance in Alumina | Benefit in 9-Hole Design |

|---|---|---|

| Conductivity | Very low | Maintains insulation |

| Integration | Moderate | High density possible |

| Reliability | Stable | Enhanced under cycles |

Reliability in Rapid Thermal Cycling

Rapid cycling creates harsh stress conditions. Two sentences explain how distributed bores moderate these effects and reduce material fatigue. One final sentence highlights their value for compact sensors.

From operational testing, rapid-cycle benefits are:

- Insulation stability across cycles

- Lower fatigue rates in ceramics

- Improved sensor durability

Application in Compact Gas Separation or Micro-Reactors

Micro-reactors require precision, and alumina tubes meet this demand. Nine channels balance flow accuracy with thermal endurance. This section focuses on these applications.

Channel Density and Flow Precision

Nine bores multiply flow pathways in the same space. Two sentences explain how this enhances process control in micro-reactors1.

A final sentence emphasizes compact efficiency.

| Factor | Effect in Fewer Bores | Effect in 9-Hole Tubes |

|---|---|---|

| Channel count | Limited precision | High precision |

| Flow control | Less accurate | Accurate |

| System scale | Larger | Compact |

Thermal Stability in PSA and Micro-Scale Units

Thermal cycles test system reliability. Two sentences explain how nine bores moderate stress and maintain integrity. A final sentence highlights benefits for PSA and reactor units.

Main outcomes from stability testing are:

- Resilience under adsorption cycles

- Reliable performance under micro-scale heat loads

- Prolonged service life in reactors

Integration in Limited-Space Designs

Compact systems require minimal footprints. Two sentences describe how 9-hole geometry saves space and maintains function. One closing sentence links this to engineering flexibility.

| Design Constraint | Effect Without 9-Hole | Effect With 9-Hole |

|---|---|---|

| Space usage | Larger footprints | Smaller footprints |

| Function density | Limited | High |

| Design flexibility | Restricted | Expanded |

Comparative View Within Alumina Multi-Bore Tubes

Performance differs with bore count, even within alumina tubes. A 9-hole design optimizes flow and stability compared with 2, 4, and 7-hole versions.

9-Hole vs. 2-Hole Tubes for Flow Control

Two-hole tubes separate flow but lack density. Two sentences explain how nine bores improve gas regulation and enable compact control. One final sentence confirms system advantage.

Key comparison factors are:

- Flow density improved in 9-hole

- Uniform regulation enhanced

- System control optimized

9-Hole vs. 4-Hole Tubes for Thermal Resistance

Four-hole tubes provide moderate stability. Two sentences explain how nine bores distribute heat loads more effectively. A final sentence links this to superior reliability.

| Property | 4-Hole Tubes | 9-Hole Tubes |

|---|---|---|

| Thermal stress | Higher | Lower |

| Durability | Moderate | High |

| Reliability | Limited | Improved |

9-Hole vs. 7-Hole Tubes for Compactness

Seven-hole tubes achieve compact integration but less density. Two sentences highlight how nine bores maximize capacity without enlarging footprint. One closing sentence stresses compact system value.

From design evaluations, compactness is improved by:

- Increased bore density

- Efficient footprint utilization

- Higher channel capacity

Engineering Considerations for Reliable Use

Reliability comes from both design and testing. Engineers must ensure machining precision and structural validation.

Wall Integrity and Crack Prevention

Wall integrity prevents premature failures under stress. Two sentences explain how density checks confirm strength. One closing sentence highlights prevention of crack growth.

| Integrity Factor | Failure Risk | Reliability Outcome |

|---|---|---|

| High density | Lower cracks | Strong durability |

| Low density | Higher cracks | Shorter lifespan |

| Controlled porosity | Balanced | Reliable service |

Channel Alignment and Machining Accuracy

Alignment determines flow balance and stress distribution. Two sentences explain how precise machining ensures predictable performance. One final sentence links accuracy with reliability.

Alignment outcomes can be summarized as:

- Parallel channels reduce imbalance

- Precision drilling supports uniform flow

- Machined accuracy ensures durability

Testing for Thermal Shock Resistance

Thermal shock testing validates cyclic performance. Two sentences highlight how heating and cooling cycles simulate real conditions. One closing sentence stresses the assurance of reliability.

| Test Aspect | Procedure | Performance Result |

|---|---|---|

| Cycle heating | Rapid heating | Validates resistance |

| Cycle cooling | Quick quenching | Confirms durability |

| Repeat cycles | Continuous testing | Ensures stability |

Summary of Advantages in Compact System Design

Summarizing contributions highlights the role of design in performance. 9-hole alumina tubes deliver predictable distribution and enhanced reliability in confined systems.

Consistent Gas Distribution in Reduced Space

Compact systems benefit from predictable gas delivery. Two sentences explain how multi-channel geometry ensures consistency. One final sentence stresses spatial efficiency.

Main observed advantages include:

- Predictable gas velocity across bores

- Compact form with high channel density

- Stable distribution during operation

Enhanced Thermal Reliability by Design

Thermal loads are distributed across multiple walls. Two sentences explain how this reduces hot spots and stress. One closing sentence emphasizes stable operation.

| Thermal Factor | Without 9-Hole | With 9-Hole |

|---|---|---|

| Hot spots | Frequent | Rare |

| Stress zones | Concentrated | Dispersed |

| Reliability | Limited | Improved |

Practical Impact for Engineering Applications

Applications gain improved performance when tubes support both flow and thermal needs. Two sentences explain how this benefits combustion, sensing, and micro-reactors. One final sentence links advantages to engineering practice.

Practical impacts for engineers are:

- Extended component life

- Reduced system failures

- Enhanced operational confidence

Conclusion

9-hole alumina ceramic tubes combine structural density and thermal stability for reliable compact systems.

Navigating compact system challenges requires stable components. Leverage ADCERAX factory-direct supply and custom engineering support to ensure reliable integration of alumina ceramic tubes in your next project.

FAQ (Frequently Asked Questions)

Q1: How do 9-hole alumina ceramic tubes improve thermal shock resistance?

They distribute stress across multiple walls, lowering crack initiation risks. This leads to stable performance during rapid heating and cooling cycles.

Q2: What cost considerations apply when selecting 9-hole alumina ceramic tubes?

Cost reflects precision machining, channel density, and durability benefits. Engineers often justify investment with extended service life and reduced failures.

Q3: How can procurement teams manage customization requests?

Suppliers can adapt bore alignment, wall thickness, and machining accuracy. Clear technical drawings improve turnaround and minimize design risks.

Q4: How do 9-hole tubes compare with other alumina multi-bore designs?

Compared with 2, 4, or 7-hole tubes, 9-hole designs maximize channel density. This improves flow uniformity and thermal reliability in compact systems.

References:

-

Learn how micro-reactors revolutionize chemical processes with enhanced control, efficiency, and scalability for advanced manufacturing and research. ↩