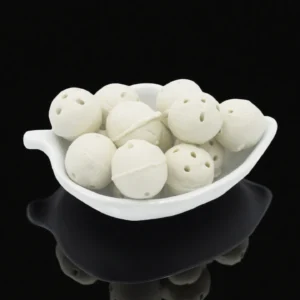

Alumina ceramic multi bores beads are open-hole support media engineered for fixed-bed hydrotreating, hydrocracking, reforming, shift, and gas-treating reactors. The multi-bore structure increases voidage and straight channels to lower pressure drop (ΔP) while providing reliable mechanical support and thermal stability.

Alumina Ceramic Multi Bores Beads Benefits

- Low pressure drop: Multi-channel paths increase voidage for measurable ΔP relief at set bed heights.

- Stable support layer: Spherical ribs give high crush strength and resist abrasion during start/stop cycles.

- Thermal/chemical margin: Alumina matrix performs in high-temperature, sulfur/amine/acid gas environments where plastics or low-temp packings fail.

Alumina Ceramic Multi Bores Beads Properties

| Item | Ordinary Porcelain Ball | 23–30% Al₂O₃ Ceramic Ball | Medium-Alumina Ceramic Ball | High-Alumina Ceramic Ball | 99 High-Alumina Ceramic Ball |

| Al₂O₃ + SiO₂ (%) | > 93 | > 92 | > 93 | > 94 | > 99 |

| Al₂O₃ (%) | 17–23 | 23–30 | 40–75 | 85–97 | 99 |

| Fe₂O₃ (%) | < 1 | < 1 | < 1 | < 1 | 0.2 |

| CaO (%) | < 0.5 | < 1.5 | < 1.5 | < 0.5 | 0.2 |

| MgO (%) | < 0.5 | < 1.5 | < 0.5 | < 0.5 | 0.1 |

| K₂O + Na₂O (%) | < 4 | < 4 | < 3.5 | < 4 | > 0.5 |

| TiO₂ (%) | < 0.5 | < 0.5 | < 0.1 | < 0.1 | 0.5 |

| Leachable Fe₂O₃ (free) (%) | < 0.1 | < 0.1 | < 0.005 | < 0.001 | — |

| Water Absorption (%) | < 0.5 | < 0.5 | < 1 | < 2 | 2–5 |

| Particle Density (g/cm³) | 2.3–2.4 | 2.3–2.4 | 2.6–2.9 | 3.4 | 3.2–3.6 |

| Max. Operating Temperature (°C) | 980 | 980 | 1450 | 1580 | 1580 |

| Mohs Hardness | > 6.5 | > 7 | > 7 | > 7.5 | > 7.5 |

| φ6 | > 0.5 | > 0.5 | > 0.5 | > 0.6 | > 1 |

| φ25 | > 6.5 | > 6.5 | > 4.9 | > 55 | > 8 |

| φ38 | > 8.9 | > 8.9 | > 5.5 | > 54 | > 8 |

| φ50 | > 9 | > 9.8 | > 6.5 | > 7.8 | > 15 |

Alumina Multi Hole Beads Specifications

Type 1: open-hole alumina support balls

| Item | Diameter(mm) |

| AT-YM-DK1001 | 6 |

| AT-YM-DK1002 | 8 |

| AT-YM-DK1003 | 10 |

| AT-YM-DK1004 | 13 |

| AT-YM-DK1005 | 15 |

| AT-YM-DK1006 | 19 |

| AT-YM-DK1007 | 25 |

| AT-YM-DK1008 | 38 |

| AT-YM-DK1009 | 50 |

Type 2: alumina ceramic 5 holes bead

| Item | Diameter(mm) |

| AT-YM-DK1001 | 6 |

| AT-YM-DK1002 | 8 |

| AT-YM-DK1003 | 10 |

| AT-YM-DK1004 | 13 |

| AT-YM-DK1005 | 15 |

| AT-YM-DK1006 | 19 |

| AT-YM-DK1007 | 25 |

| AT-YM-DK1008 | 38 |

| AT-YM-DK1009 | 50 |

Type 3: alumina ceramic 7 holes bead

| Item | Diameter(mm) |

| AT-YM-DK1001 | 6 |

| AT-YM-DK1002 | 8 |

| AT-YM-DK1003 | 10 |

| AT-YM-DK1004 | 13 |

| AT-YM-DK1005 | 15 |

| AT-YM-DK1006 | 19 |

| AT-YM-DK1007 | 25 |

| AT-YM-DK1008 | 38 |

| AT-YM-DK1009 | 50 |

Alumina Ceramic Multi Bores Beads Packaging

- High alumina grinding beads are packaged in 25 kg heavy-duty plastic bags, which are then placed inside 1-ton jumbo bags with inner waterproof liners. The jumbo bags are palletized and shrink-wrapped for secure, moisture-free international transport.