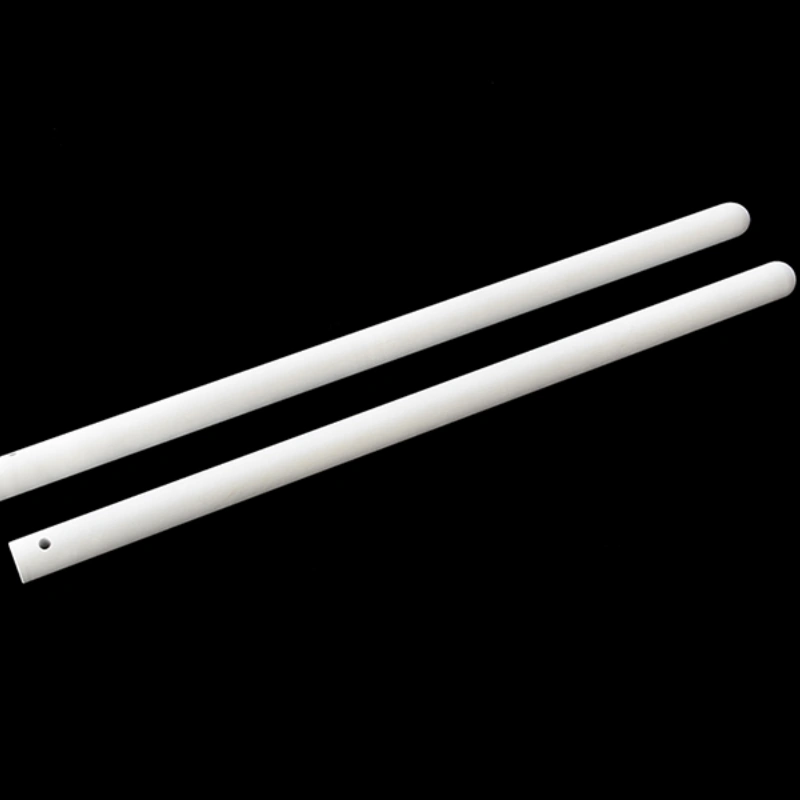

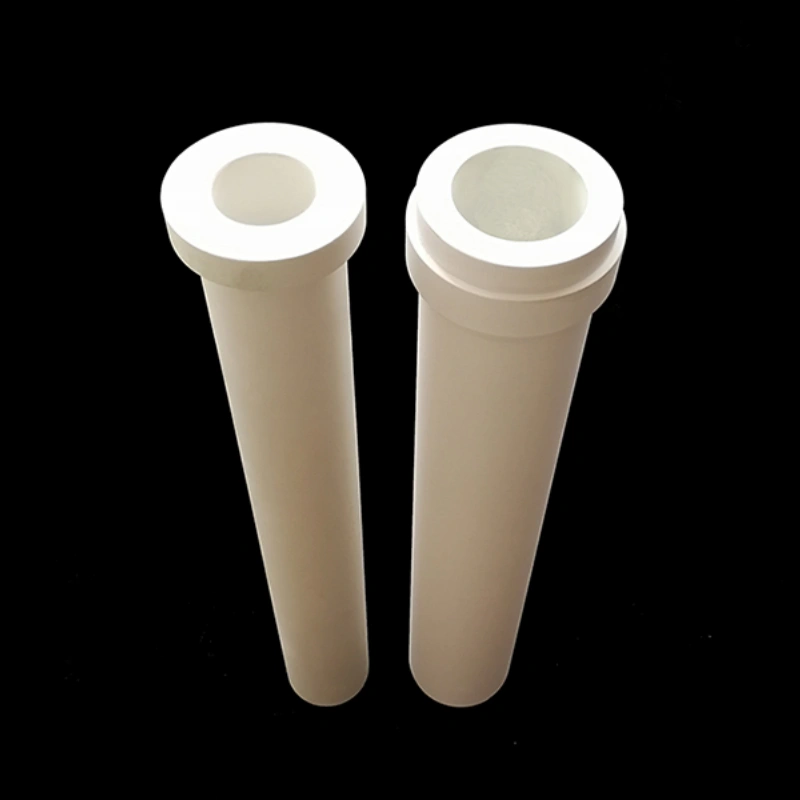

An Aluminum Titanate Riser Tube is a ceramic stalk made of Al₂TiO₅, used in low-pressure die casting and dosing furnace systems to lift molten aluminum from a holding or dosing furnace into the mold under controlled gas pressure. It combines a very low thermal expansion coefficient, good thermal shock resistance and non-wetting behavior toward molten aluminum, so it can withstand repeated 700–900 °C casting cycles with reduced cracking, limited metal build-up and more stable metal flow compared with steel or conventional ceramic tubes.

Aluminum Titanate Riser Tube Benefits

-

Low thermal expansion for thermal cycling

The Al₂TiO₅ body of the Aluminum Titanate Riser Tube shows a very low thermal expansion coefficient below 1×10⁻⁶ K⁻¹, which helps the tube withstand frequent cycles between room temperature and ≥700 °C without severe thermal stress cracking. -

Non-wetting interface to molten aluminium

Aluminum titanate exhibits poor wettability by aluminium alloys, so the riser tube inner surface resists metal sticking and dross adhesion, reducing blockage, inclusion release and cleaning work during LPDC production. -

Insulating wall to support uniform temperature

With thermal conductivity around 1.5 W/m·K, Aluminum Titanate Riser Tube limits heat loss along the molten metal column, supporting consistent metal temperature and filling behaviour from furnace to die. -

Gas-tight microstructure for controlled gas pressure

The ceramic microstructure can be manufactured to achieve low permeability to gas, helping maintain the pressure differential required in low-pressure casting cycles while limiting gas leakage along the riser. -

Service life suited to continuous LPDC operation

When matched correctly to the alloy, furnace temperature (typically 700–750 °C) and operating cycle, Aluminum Titanate Riser Tube can reach multi-week service life, which supports fewer tube changes and more stable production campaigns.

Aluminum Titanate Riser Tube Properties

| Parameter | Typical Value | Description |

| Coefficient of Thermal Expansion (CTE) | 0.5–1.5 ×10⁻⁶ /K | Extremely low expansion that maintains dimensional stability under molten aluminum temperatures. |

| Thermal Shock Resistance | Very high | Withstands rapid temperature fluctuations without cracking during casting cycles. |

| Density | 2.8–3.0 g/cm³ | Medium-density ceramic structure suitable for molten aluminum system components. |

| Thermal Conductivity | 1.5–3.0 W/m·K | Helps reduce heat loss along riser tubes, spouts and transfer components. |

| Maximum Service Temperature | 900–1100°C | Suitable for typical molten-aluminum environments and transfer systems. |

| Flexural Strength (MOR) | 10–25 MPa | Provides sufficient strength for handling, installation and operational load. |

| Elastic Modulus | 20–40 GPa | Lower stiffness contributes to excellent thermal shock tolerance. |

| Porosity | 12–25% | Supports insulation and limits internal thermal stress accumulation. |

| Chemical Compatibility | Non-wetting to molten aluminum | Prevents adhesion, oxide buildup and contamination in casting processes. |

| Dimensional Stability | Stable through long cycles | Maintains geometry during prolonged molten-aluminum exposure and thermal cycling. |

Aluminum Titanate Riser Tube Specifications

| Item | Outer Dia (mm) | Inner Dia (mm) | Length (mm) |

| AT-TSL-SYG1001 | 78 | 58 | 850 |

| AT-TSL-SYG1002 | 90 | 61 | 850 |

| AT-TSL-SYG1003 | 100 | 80 | 400 |

| AT-TSL-SYG1004 | 100 | 60 | 900 |

| AT-TSL-SYG1005 | 100 | 60 | 970 |

| AT-TSL-SYG1006 | 105 | 75 | 1050 |

| AT-TSL-SYG1007 | 110 | 63.5 | 900 |

| AT-TSL-SYG1008 | 114 | 68 | 1100 |

| AT-TSL-SYG1009 | 120 | 100 | 600 |

| AT-TSL-SYG1010 | 120 | 100 | 800 |

| AT-TSL-SYG1011 | 120 | 70 | 1220 |

| AT-TSL-SYG1012 | 120 | 80 | 950 |

| AT-TSL-SYG1013 | 120 | 80 | 930 |

| AT-TSL-SYG1014 | 130 | 110 | 1063 |

| AT-TSL-SYG1015 | 130 | 100 | 750 |

Aluminium Titanate Riser Tube Packaging

- Each Aluminum Titanate Riser Tube is wrapped in shock-absorbing material (foam or soft padding) to protect ceramic surfaces from impact during transport