-

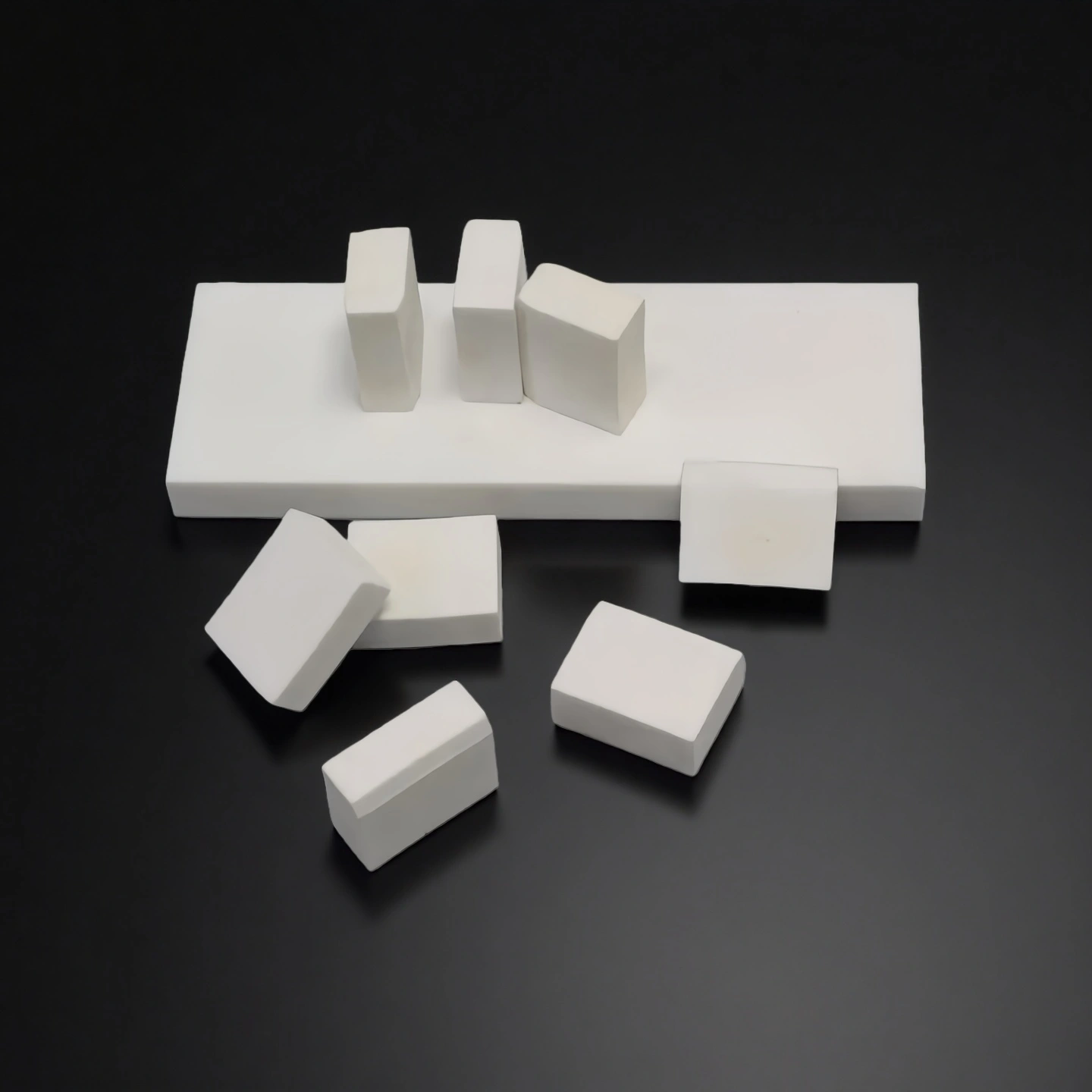

Precision-fit machining for multi-feature plates: A machinable glass ceramic plate supports tight, repeatable machining for hole patterns, slots, pockets, and datum surfaces, with published guidance indicating tolerance potential down to ±0.013 mm on suitable dimensions and setups.

-

Temperature capability for insulating structures: A machinable glass ceramic plate is specified for high-temperature insulation fixtures where geometry must remain stable, with typical published limits of 800°C continuous under load and 1000°C peak under no-load conditions.

-

High-voltage dielectric performance for compact layouts: A machinable glass ceramic plate is used when electrical isolation must be maintained in limited space, supported by published dielectric strength figures of 45 kV/mm (AC) and 129 kV/mm (DC) under stated test conditions.

-

Thermal break behaviour from low conductivity: A machinable glass ceramic plate helps reduce heat transfer through a structure compared with many dense ceramics, with a published thermal conductivity of 1.46 W/m·K at 25°C, which is useful for thermal isolation interfaces.

-

Dense, non-porous microstructure for clean assemblies: A machinable glass ceramic plate is produced as a zero-porosity material, which supports vacuum-compatible and contamination-controlled builds when the part is properly cleaned, handled, and prepared for the application.

Machinable Glass Ceramic Sheet Properties

| Machinable Glass Ceramic Physical Properties | ||

| Property | Typical value | Notes |

| Purity | ≥ 99.9 % | Some grades can reach 99.99 % |

| Density | 2.5–2.6 g/cm³ | Archimedes method |

| Open porosity | ≤ 0.07 % | Effectively non-porous |

| Water absorption | 0 % | No measurable uptake |

| Colour | White | Clean, uniform appearance |

| Hardness (Mohs) | 4–5 (up to 6–7) | Depending on grade |

| Machinable Glass Ceramic Thermal Properties | ||

| Property | Typical value | Notes |

| Coefficient of thermal expansion (CTE) | 72 × 10⁻⁷ /°C | Average from −50 to 200 °C |

| CTE 25–300 °C | 90 × 10⁻⁷ /°C | For design over mid-range temperatures |

| CTE 25–600 °C | 112 × 10⁻⁷ /°C | |

| CTE 25–800 °C | 123 × 10⁻⁷ /°C | |

| Thermal conductivity | 1.7 W/m·K | At 25 °C |

| Continuous use temperature | ~800 °C | Long-term service |

| Short-term maximum temperature | ~1000 °C | Depends on load and atmosphere |

| Machinable Glass Ceramic Mechanical Properties | ||

| Property | Typical value | Notes |

| Young’s modulus | ≈ 65 GPa | Room temperature |

| Flexural strength | ≥ 100 MPa | Three-point bending |

| Compressive strength | ≥ 500 MPa | Room temperature |

| Impact resistance | ≥ 2.56 kJ/m² | Indicative value for brittle fracture |

| Poisson’s ratio | ≈ 0.29 | |

| Shear modulus | ≈ 25 GPa | Derived from E and ν |

| Machinable Glass Ceramic Electrical Properties | ||

| Property | Typical value | Notes |

| Dielectric constant (1 kHz) | 6–7 | 25 °C |

| Dielectric loss (tan δ, 1 kHz) | 1–4 × 10⁻³ | 25 °C |

| Dielectric strength | > 40 kV/mm | Sample thickness 1 mm |

| Volume resistivity @ 25 °C | ≈ 1.0 × 10¹⁶ Ω·cm | High insulation level |

| Volume resistivity @ 200 °C | ≈ 1.5 × 10¹² Ω·cm | |

| Volume resistivity @ 500 °C | ≈ 1.1 × 10⁹ Ω·cm | |

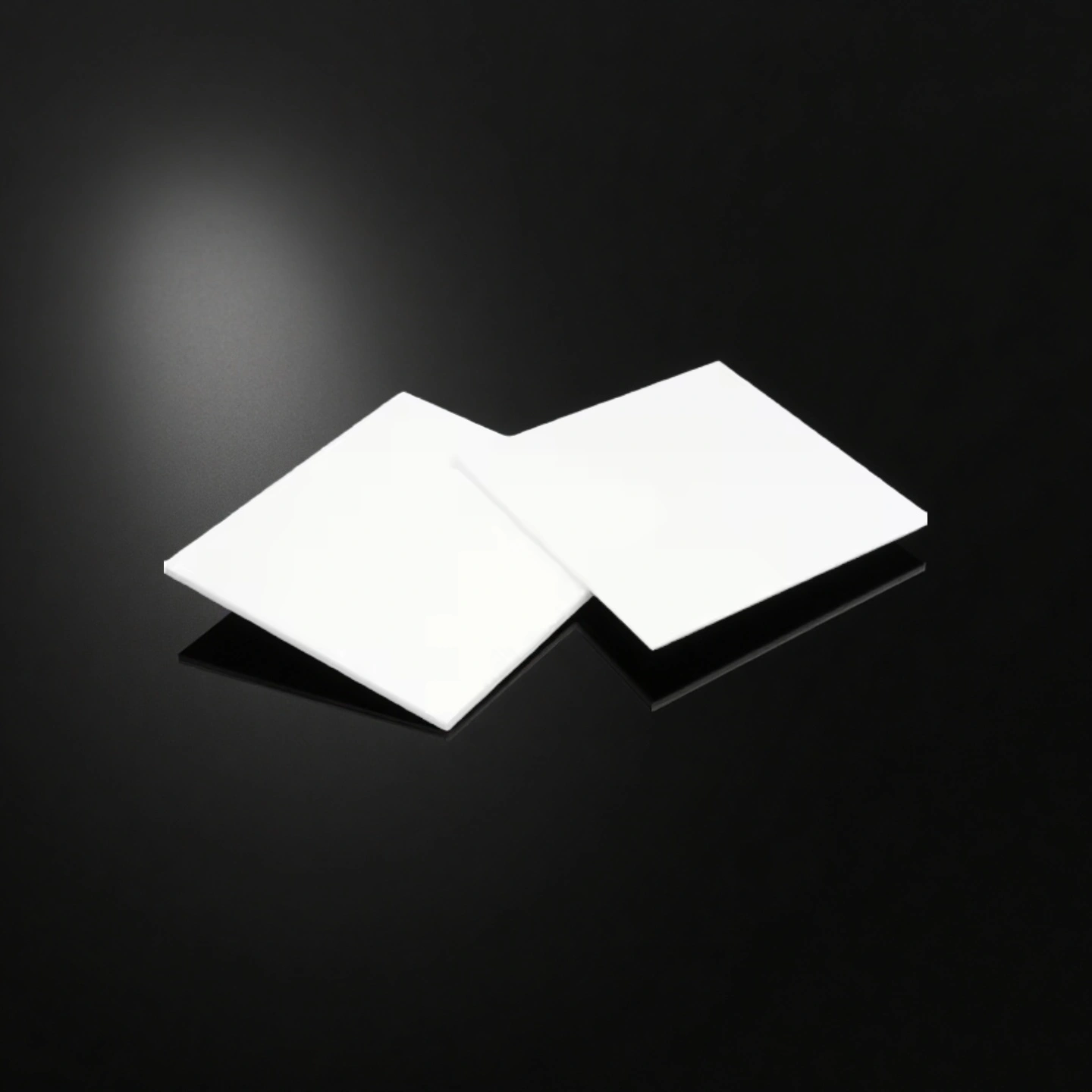

Machinable Glass Ceramic Plate Specifications

Type 1: Square Machinable Glass Ceramic Plate

| Square Machinable Glass Ceramic Plate | ||

| Item | Length *Width *Hight (mm) | Thickness (mm) |

| AT-KJG-TC1001 | 50*50 | 5 |

| AT-KJG-TC1002 | 50*50 | 10 |

| AT-KJG-TC1003 | 100*50 | 5 |

| AT-KJG-TC1004 | 100*50 | 10 |

| AT-KJG-TC1005 | 100*100 | 3 |

| AT-KJG-TC1006 | 100*100 | 5 |

| AT-KJG-TC1007 | 100*100 | 10 |

| AT-KJG-TC1008 | 90*140 | 5 |

| AT-KJG-TC1009 | 95*145 | 8 |

| AT-KJG-TC1010 | 150*150 | 10 |

| AT-KJG-TC1011 | 160*160 | 12 |

| AT-KJG-TC1012 | 122*290 | 15 |

| AT-KJG-TC1013 | 110*275 | 18 |

| AT-KJG-TC1014 | 200*100 | 5 |

| AT-KJG-TC1015 | 200*100 | 10 |

| AT-KJG-TC1016 | 300*200 | 50 |

| AT-KJG-TC1017 | 50-450 custom | 5-50 custom |

Type 2: Round Machinable Glass Ceramic Plate

| Round Machinable Glass Ceramic Plate | ||

| Item | Diameter (mm) | Thickness (mm) |

| AT-KJG-TC1020 | 10 | 5 |

| AT-KJG-TC1021 | 20 | 8 |

| AT-KJG-TC1022 | 25 | 9.5 |

| AT-KJG-TC1023 | 30 | 12 |

| AT-KJG-TC1024 | 50 | 20 |

| AT-KJG-TC1025 | 70 | 20 |

| AT-KJG-TC1026 | 100 | 20 |

| AT-KJG-TC1027 | 10-300 | 5-50 |

Machinable Glass Ceramic Plate Packaging

- Individual part protection to avoid edge chipping during transport