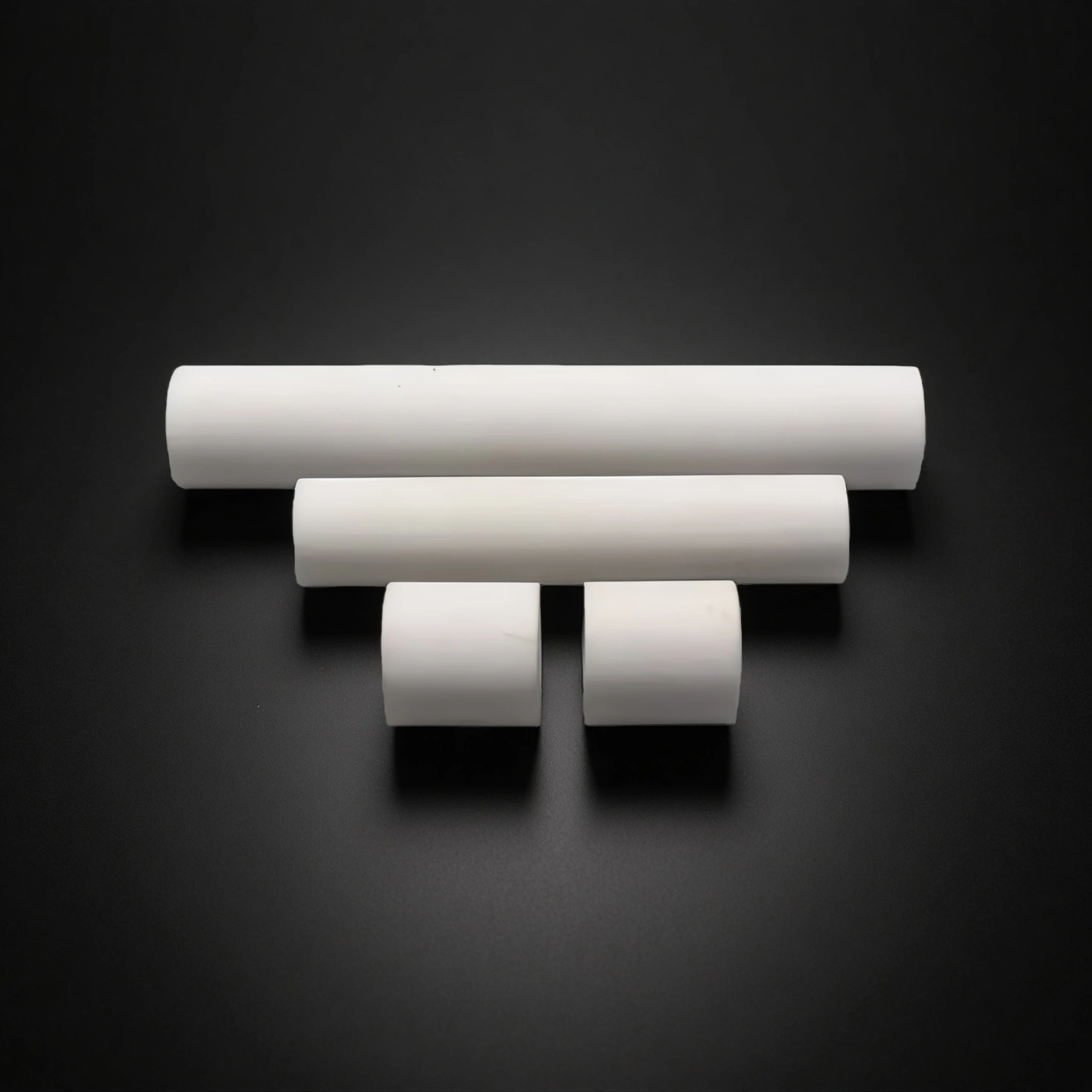

A machinable glass ceramic rod is a cylindrical bar of glass-ceramic that can be turned, milled and drilled with standard metalworking tools. It combines high-temperature and electrical insulating properties with easy machining, so it is widely used as bar stock for custom supports and insulators in vacuum, high-voltage and lab equipment.

Machinable Glass Ceramic Rod Benefits

-

Direct Machinability from Rod Stock

Machinable glass ceramic rods can be cut and turned with conventional carbide tools, allowing tight tolerances and complex geometries without post-firing or sintering. -

High-Temperature and Electrical Insulation in One Material

Each machinable glass ceramic rod combines continuous service up to around 800 °C with high dielectric strength, supporting compact high-voltage and heater assemblies in a single part. -

Low Outgassing and Zero Porosity

The dense, non-porous microstructure helps machinable glass ceramic rods meet vacuum and UHV cleanliness requirements after proper bake-out. -

Stable Thermal Expansion Matching Metals

Rods provide thermal expansion close to common steels and sealing glasses, reducing stress at metal–ceramic joints and improving alignment stability. -

Dimensional Stability for Precision Fixtures

Machinable glass ceramic rods maintain straightness and geometry under thermal cycling, supporting precision jigs, optical mounts and RF fixtures.

Machinable Glass Ceramic Rod Properties

| Machinable Glass Ceramic Physical Properties | ||

| Property | Typical value | Notes |

| Purity | ≥ 99.9 % | Some grades can reach 99.99 % |

| Density | 2.5–2.6 g/cm³ | Archimedes method |

| Open porosity | ≤ 0.07 % | Effectively non-porous |

| Water absorption | 0 % | No measurable uptake |

| Colour | White | Clean, uniform appearance |

| Hardness (Mohs) | 4–5 (up to 6–7) | Depending on grade |

| Machinable Glass Ceramic Thermal Properties | ||

| Property | Typical value | Notes |

| Coefficient of thermal expansion (CTE) | 72 × 10⁻⁷ /°C | Average from −50 to 200 °C |

| CTE 25–300 °C | 90 × 10⁻⁷ /°C | For design over mid-range temperatures |

| CTE 25–600 °C | 112 × 10⁻⁷ /°C | |

| CTE 25–800 °C | 123 × 10⁻⁷ /°C | |

| Thermal conductivity | 1.7 W/m·K | At 25 °C |

| Continuous use temperature | ~800 °C | Long-term service |

| Short-term maximum temperature | ~1000 °C | Depends on load and atmosphere |

| Machinable Glass Ceramic Mechanical Properties | ||

| Property | Typical value | Notes |

| Young’s modulus | ≈ 65 GPa | Room temperature |

| Flexural strength | ≥ 100 MPa | Three-point bending |

| Compressive strength | ≥ 500 MPa | Room temperature |

| Impact resistance | ≥ 2.56 kJ/m² | Indicative value for brittle fracture |

| Poisson’s ratio | ≈ 0.29 | |

| Shear modulus | ≈ 25 GPa | Derived from E and ν |

| Machinable Glass Ceramic Electrical Properties | ||

| Property | Typical value | Notes |

| Dielectric constant (1 kHz) | 6–7 | 25 °C |

| Dielectric loss (tan δ, 1 kHz) | 1–4 × 10⁻³ | 25 °C |

| Dielectric strength | > 40 kV/mm | Sample thickness 1 mm |

| Volume resistivity @ 25 °C | ≈ 1.0 × 10¹⁶ Ω·cm | High insulation level |

| Volume resistivity @ 200 °C | ≈ 1.5 × 10¹² Ω·cm | |

| Volume resistivity @ 500 °C | ≈ 1.1 × 10⁹ Ω·cm | |

Machinable Glass Ceramic Bar Specifications

| Machinable Glass Ceramic Rod | ||

| Item | Diameter (mm) | Width (mm) |

| AT-KJG-TC2001 | 0.5 | 60 |

| AT-KJG-TC2002 | 1 | 100 |

| AT-KJG-TC2003 | 2 | 120 |

| AT-KJG-TC2004 | 5 | 200 |

| AT-KJG-TC2005 | 10 | 100 |

| AT-KJG-TC2006 | 15 | 100 |

| AT-KJG-TC2007 | 20 | 100 |

| AT-KJG-TC2008 | 25 | 100 |

| AT-KJG-TC2009 | 30 | 100 |

| AT-KJG-TC2010 | 35 | 100 |

| AT-KJG-TC2011 | 40 | 100 |

| AT-KJG-TC2012 | 45 | 100 |

| AT-KJG-TC2013 | 50 | 100 |

| AT-KJG-TC2014 | 55 | 100 |

| AT-KJG-TC2015 | 60 | 100 |

| AT-KJG-TC2016 | 65 | 100 |

| AT-KJG-TC2017 | 70 | 100 |

| AT-KJG-TC2018 | 75 | 100 |

| AT-KJG-TC2019 | 80 | 100 |

| AT-KJG-TC2020 | 85 | 100 |

| AT-KJG-TC2021 | 90 | 100 |

| AT-KJG-TC2022 | 95 | 100 |

| AT-KJG-TC2023 | 100 | 100 |

| AT-KJG-TC2024 | 105 | 100 |

| AT-KJG-TC2025 | 110 | 100 |

| AT-KJG-TC2026 | 115 | 100 |

| AT-KJG-TC2027 | 120 | 100 |

| AT-KJG-TC2028 | 0.5-200 (Custom) | 10-300 (Custom) |

Machinable Glass Ceramic Bar Packaging

- Each machinable glass ceramic rod is first wrapped in soft film or foam sleeves to prevent chipping of edges and ends.