A High Purity Alumina Ceramic Insulating Ring is a ring-shaped component made from high-purity Al₂O₃ ceramic (typically ≥99.5% alumina) that provides electrical insulation and controlled spacing between metal parts in demanding environments. It is used in vacuum chambers, plasma and coating equipment, high-temperature furnaces, and high-voltage assemblies.

High-Purity Alumina Ceramic Insulating Ring Benefits

-

Stack-up stability

The High Purity Alumina Ceramic Insulating Ring is machined with controlled thickness and flat contact faces so clamp load is shared evenly, helping keep fixture stack-up height, gap spacing, and torque settings consistent from build to build. -

Edge integrity options

Chamfers or radii can be applied to the alumina ceramic insulating ring and edges are finished burr-free to lower the risk of handling chips, reduce local stress concentration, and limit unwanted electrical tracking along sharp corners. -

Interface-ready surfaces

Functional faces of the High Purity Alumina Ceramic Insulating Ring can be supplied as ground or lapped, giving a defined surface texture that supports repeatable metal–ceramic contact geometry and stable sealing or contact resistance. -

Fit-up control

OD/ID concentricity, roundness, and parallelism can be held to specified targets so the ring locates accurately in recesses or on pilots, helping reduce assembly rework, shim adjustments, and time spent tuning alignment. -

Service-friendly design

Grooves, reliefs, and alignment features can be integrated into the High Purity Alumina Ceramic Insulating Ring to avoid contamination traps, guide orientation during maintenance, and simplify removal and replacement in confined fixtures.

High-Purity Alumina Insulating Ring Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

High-Purity Alumina Insulating Ring Specifications

| Alumina Insulating Ring | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-HP-JY01 | Customize | |

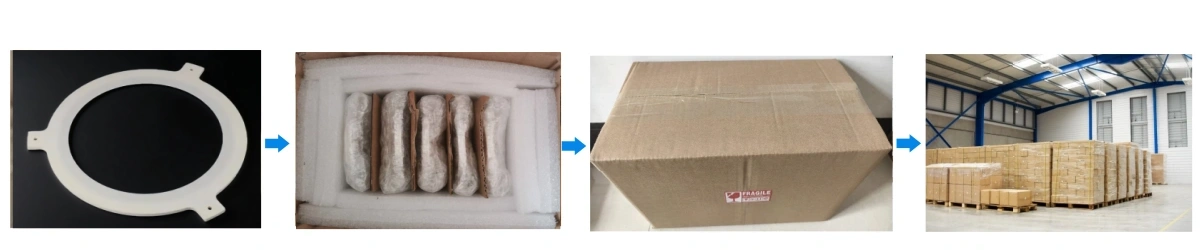

High-Purity Alumina Insulating Ring Packaging

- Individual protective sleeve or bag to prevent surface abrasion

- Foam cavities or layered partitions to isolate rings from impact