Alumina Substrate choices often surface when FR4 begins to saturate thermal headroom, insulation margins, or lifetime targets. Consequently, this comparison clarifies where performance risk accumulates and where design latitude remains.

This technical article aligns substrate physics with power density, dielectric stability, and lifecycle reliability. Moreover, it consolidates design constraints, manufacturing realities, and qualification logic for high-duty electronics.

Accordingly, the narrative moves from material fundamentals to system behavior under stress. Thereafter, it converges on selection criteria that engineers can defend during design reviews and reliability audits.

Additionally, this overview anchors key trade-offs between Alumina Substrate and FR4 using repeatable engineering reasoning. Consequently, each section connects measurable properties to failure mechanisms that matter in power electronics and industrial deployments.

Why Substrate Choice Shapes Power Electronic Systems

Substrate selection sets the boundary conditions for heat, voltage, and strain in every power stage. Consequently, Alumina Substrate and FR4 decisions influence not only performance, but also failure probability over years of thermal cycling.

-

Thermal headroom becomes a system bottleneck

Power devices rarely fail because average board temperature looks high; instead, localized hotspots accumulate where the thermal path is weakest. Consequently, FR4 can appear acceptable in short validation runs yet drift in junction temperature during extended loads. In contrast, Alumina Substrate architectures usually suppress steep gradients, which stabilizes electrical parameters over long duty cycles. -

Electrical insulation evolves with temperature and time

Dielectric strength is not a static datasheet value once humidity, elevated temperature, and field stress coexist. Therefore, insulation aging can progress quietly until partial discharge or leakage becomes measurable. Moreover, Alumina Substrate platforms typically preserve dielectric stability across wider temperature bands than FR4 laminates under comparable stress. -

Thermomechanical strain accumulates into fatigue failures

Every power cycle imposes expansion mismatch between copper, solder, and the substrate body. As a result, fatigue damage concentrates at interconnects and metallization edges even when initial assembly quality is high. Furthermore, Alumina Substrate stiffness can reduce warpage-driven strain, while FR4 compliance can increase cyclic deformation once temperature approaches resin softening regimes.

Consequently, a substrate decision should be treated as a reliability architecture choice rather than a cost-only bill-of-material line item.

Material Foundations of Alumina and FR4

Material foundations establish the irreversible boundaries within which electrical, thermal, and mechanical behaviors evolve. Therefore, before performance metrics are compared, intrinsic material structure must be examined as the root cause of long-term stability or degradation. Moreover, alumina ceramics and FR4 composites differ fundamentally at the atomic and microstructural levels, which explains why their behaviors diverge under power and temperature stress.

Crystal ceramic architecture of alumina substrates

Alumina substrates are built upon a dense, polycrystalline aluminum oxide lattice, typically exceeding 96% to 99.6% Al₂O₃ purity. This ceramic crystal framework forms a continuous solid with minimal internal phase boundaries.

In engineering practice, this structure delivers high isotropy, meaning thermal expansion, stiffness, and heat conduction remain consistent in all planar directions. During qualification testing of power modules, engineers often observe that alumina substrates maintain dimensional flatness within ±15–25 μm even after 500–1,000 thermal cycles between room temperature and 150 °C. Additionally, the absence of polymer phases eliminates softening or creep mechanisms that would otherwise amplify strain over time.

As a result, alumina’s crystal architecture provides a stable physical reference plane that resists both short-term thermal shock and long-term mechanical relaxation.

Glass fiber epoxy composite structure of FR4

FR41 substrates rely on a laminated composite of woven glass fibers embedded in epoxy resin, creating a heterogeneous material system by design. This layered construction enables cost-effective manufacturing but introduces directional dependencies and temperature-sensitive behavior.

Under moderate temperatures, glass fibers carry mechanical load while the epoxy matrix binds layers together. However, once operating temperatures approach the glass transition range of 130–170 °C, resin modulus drops sharply, and the composite’s effective stiffness decreases. In accelerated life testing, engineers frequently measure CTE values rising above 60–70 ppm/K beyond Tg, leading to progressive warpage and copper trace strain even when initial assembly quality is high.

Consequently, FR4’s composite nature embeds a temperature-dependent structural ceiling that cannot be removed through layout optimization alone.

Structural continuity versus layered heterogeneity

The contrast between alumina and FR4 ultimately reduces to structural continuity versus layered heterogeneity. Alumina behaves as a single, unified solid, while FR4 functions as a mechanically cooperative system of dissimilar phases.

In real-world evaluations, this difference becomes evident during long-duration thermal dwell tests. Alumina substrates typically show negligible permanent deformation after extended exposure at 200 °C, whereas FR4 assemblies often exhibit cumulative warpage that increases cycle-to-cycle strain at solder joints. Moreover, heterogeneous interfaces in FR4 act as stress concentrators, whereas alumina distributes stress more uniformly across its volume.

Therefore, the material foundation itself predetermines how stress accumulates and how reliably the substrate can serve as a long-term mechanical and thermal reference.

Summary of Material Foundation Differences

| Attribute | Alumina Substrate | FR4 |

|---|---|---|

| Primary Structure | Polycrystalline ceramic | Glass fiber epoxy composite |

| Purity / Composition | >96–99.6% Al₂O₃ | Glass fiber + epoxy resin |

| Young’s Modulus (GPa) | 300–380 | 18–24 |

| Glass Transition Behavior | None | 130–170 °C |

| Structural Isotropy | High | Direction-dependent |

| Long-Term Dimensional Stability | Excellent | Degrades near Tg |

Thermal Transport Behavior Under Power Density Stress

Thermal transport defines whether electrical performance remains stable or drifts under sustained load. Therefore, substrate behavior must be evaluated under power density stress, not nominal operating temperatures alone. Moreover, alumina and FR4 manage heat through fundamentally different physical pathways, which causes divergence once localized dissipation intensifies.

Heat conduction paths in ceramic substrates

Alumina substrates conduct heat through a continuous crystalline lattice, enabling relatively uniform phonon transport across the substrate body. Consequently, thermal resistance remains predictable even when heat sources are highly concentrated.

In practical power module testing, alumina substrates typically exhibit thermal conductivity between 20–30 W/m·K, allowing heat to spread laterally before transferring to external heat sinks. During LED array characterization, engineers often measure junction temperature reductions of 15–25 °C compared with FR4 at identical drive currents and airflow conditions. Furthermore, because ceramic lacks resin phases, thermal conductivity remains stable across wide temperature ranges rather than degrading near softening points.

As a result, alumina substrates transform localized heat into manageable gradients instead of permitting thermal accumulation beneath active devices.

Thermal bottlenecks inherent to FR4 laminates

FR4 laminates rely on epoxy-dominated pathways for heat flow, which inherently restrict thermal transport. As a result, heat removal efficiency depends heavily on copper thickness, via density, and external cooling aids.

Measured thermal conductivity of FR4 typically falls between 0.3–0.4 W/m·K, nearly two orders of magnitude lower than alumina. In extended burn-in testing of power converters, engineers frequently observe localized copper temperatures exceeding 110–120 °C while average board temperature remains below alarm thresholds. Additionally, repeated exposure to these gradients accelerates resin aging and delamination, further degrading heat flow over time.

Consequently, FR4 creates self-reinforcing thermal bottlenecks where heat concentration worsens with service duration.

Power density thresholds and thermal runaway risk

Thermal runaway risk increases sharply once power density exceeds a substrate’s ability to redistribute heat laterally. Therefore, identifying threshold behavior is critical during early design decisions.

For FR4-based assemblies, instability commonly appears beyond 3–5 W/cm², particularly when ambient temperatures exceed 50 °C or airflow is restricted. By contrast, alumina substrates often sustain 10 W/cm² or higher without entering runaway regimes under comparable cooling conditions. In qualification trials, engineers consistently report that FR4 boards approach unstable equilibrium during long-duration full-load tests, whereas alumina systems converge toward steady-state thermal balance.

Accordingly, power density serves as a decisive boundary where substrate choice transitions from cost optimization to reliability preservation.

Summary of Thermal Transport Performance

| Metric | Alumina Substrate | FR4 |

|---|---|---|

| Thermal Conductivity (W/m·K) | 20–30 | 0.3–0.4 |

| Lateral Heat Spreading | High | Limited |

| Stable Power Density (W/cm²) | ≥10 | ≤5 |

| Thermal Property Stability with Temperature | High | Degrades near Tg |

| Runaway Risk Under Sustained Load | Low | Elevated |

Electrical Insulation and Dielectric Stability

Electrical insulation performance governs leakage behavior, signal integrity, and long-term safety margins in power electronics. Therefore, dielectric stability must be evaluated under combined electrical, thermal, and temporal stress rather than at room-temperature datasheet conditions. Moreover, alumina substrates and FR4 respond very differently once temperature elevation and sustained electric fields coexist.

Dielectric loss behavior at elevated temperature

Alumina substrates exhibit inherently low dielectric loss due to their stable ceramic lattice and minimal dipolar polarization mechanisms. Consequently, dielectric properties remain consistent even as operating temperature increases.

In measured evaluations, alumina typically maintains a dielectric constant of 9–10 with a loss tangent below 0.0005 across frequencies up to several megahertz. During prolonged high-temperature operation at 150–200 °C, engineers often observe negligible drift in impedance or signal attenuation. Furthermore, the absence of polymer chains eliminates thermally activated dipole relaxation2, which commonly increases dielectric loss in organic materials.

As a result, alumina substrates preserve signal and insulation performance under electrical stress conditions that would destabilize polymer-based systems.

Breakdown strength and long-term insulation aging

Dielectric breakdown is not an instantaneous event but the outcome of progressive insulation aging. Therefore, long-term exposure behavior carries greater relevance than initial breakdown voltage.

Alumina substrates typically demonstrate dielectric strength exceeding 10–15 kV/mm, with minimal degradation after thousands of thermal cycles. In contrast, FR4 insulation strength declines measurably as epoxy resin absorbs moisture and undergoes thermal oxidation. Field reliability studies frequently record leakage current increases of 20–40% in FR4 assemblies after extended operation above 100 °C, even when voltage stress remains unchanged.

Consequently, insulation aging mechanisms favor ceramic substrates in applications requiring sustained high-voltage stability.

Frequency stability and partial discharge resistance

Electrical insulation performance also depends on resistance to partial discharge and frequency-induced stress. These phenomena often emerge silently before catastrophic failure.

Alumina’s dense ceramic structure suppresses microvoid formation, reducing sites where partial discharge can initiate. In high-frequency inverter testing above 50 kHz, alumina substrates consistently show stable capacitance and minimal discharge activity. Conversely, FR4 laminates may develop interfacial voids and resin microcracks, particularly near copper edges, which promote discharge under combined electrical and thermal stress.

Therefore, alumina substrates provide a more robust dielectric environment for high-frequency and high-voltage power electronics.

Summary of Electrical Insulation Performance

| Parameter | Alumina Substrate | FR4 |

|---|---|---|

| Dielectric Constant | 9–10 | 4.2–4.8 |

| Loss Tangent | <0.0005 | 0.015–0.02 |

| Dielectric Strength (kV/mm) | 10–15 | 3–5 |

| Stability at Elevated Temperature | Excellent | Degrades |

| Partial Discharge Resistance | High | Moderate |

Thermomechanical Compatibility and Structural Integrity

Thermomechanical compatibility dictates how reliably a substrate endures repeated thermal excursions without accumulating irreversible damage. Therefore, expansion behavior, stiffness, and interfacial stress must be assessed together rather than as isolated properties. Moreover, alumina substrates and FR4 respond fundamentally differently once cyclic temperature gradients interact with copper, solder, and component bodies.

Coefficient of thermal expansion mismatch effects

Thermal expansion mismatch between substrate and metallization is a primary driver of fatigue-related failures. Consequently, even modest differences in CTE can translate into substantial cyclic strain at interfaces.

Alumina substrates typically exhibit a CTE of 6–8 ppm/K, closely matching copper and common ceramic components. In contrast, FR4 shows in-plane CTE values around 14–17 ppm/K below Tg and can exceed 60 ppm/K above Tg. During thermal cycling between 25 °C and 150 °C, engineers frequently measure 30–50% higher shear strain at solder joints on FR4 compared with alumina-based assemblies.

As a result, alumina substrates reduce strain accumulation per cycle, directly extending interconnect fatigue life.

Warpage fracture and fatigue mechanisms

Structural integrity is not solely about strength but about how deformation accumulates over time. Therefore, warpage behavior under thermal load becomes a critical reliability indicator.

In accelerated cycling tests, FR4 assemblies often develop progressive board curvature as epoxy modulus decreases with temperature. This warpage concentrates stress at copper trace corners and component leads, leading to microcrack initiation after 500–1,000 cycles. Conversely, alumina substrates maintain high stiffness, typically above 300 GPa, which limits out-of-plane deformation and preserves planar stability across thousands of cycles.

Consequently, alumina substrates suppress secondary failure mechanisms that originate from cumulative warpage rather than immediate overload.

Structural continuity under long-term thermal exposure

Long-term exposure to elevated temperature reveals whether structural integrity is preserved or gradually compromised. Accordingly, creep and relaxation behavior must be considered alongside static strength.

FR4 exhibits measurable viscoelastic creep once temperatures exceed 100–120 °C, causing gradual stress redistribution and loss of mechanical preload. In contrast, alumina ceramics demonstrate negligible creep under comparable conditions, even after 1,000 hours at elevated temperature. Field experience consistently shows that alumina-based modules retain mechanical alignment and contact integrity far longer than FR4 counterparts.

Therefore, structural continuity under sustained thermal exposure favors ceramic substrates in high-duty applications.

Summary of Thermomechanical Compatibility

| Parameter | Alumina Substrate | FR4 |

|---|---|---|

| Coefficient of Thermal Expansion (ppm/K) | 6–8 | 14–17 (≤Tg), >60 (>Tg) |

| Elastic Modulus (GPa) | 300–380 | 18–24 |

| Warpage Under Thermal Cycling | Minimal | Progressive |

| Creep at Elevated Temperature | Negligible | Measurable |

| Fatigue Resistance of Interconnects | High | Moderate to Low |

Manufacturing Constraints and Design Freedom

Manufacturing constraints define how theoretical material advantages translate into practical designs. Therefore, substrate selection must consider not only performance ceilings but also routing density, interconnection methods, and process maturity. Moreover, alumina substrates and FR4 impose fundamentally different boundaries on layout freedom and production scalability.

Multilayer routing and design density limitations

Design freedom in power electronics often depends on achievable routing density and layer count. Consequently, substrate architecture directly influences how compact and complex a circuit can become.

FR4 supports multilayer constructions exceeding 10 layers, with fine-line routing below 100 µm achievable through mature PCB fabrication processes. This capability allows dense signal integration and flexible power distribution within a compact footprint. In contrast, alumina substrates are typically implemented as single-layer or limited multilayer structures, where line widths of 150–200 µm are more common due to ceramic processing constraints.

As a result, alumina substrates prioritize thermal and electrical robustness over extreme routing density.

Metallization and interconnection approaches

Electrical interconnection on ceramic substrates relies on specialized metallization techniques rather than standard copper lamination. Therefore, process selection strongly influences both performance and cost.

Common alumina metallization methods include thick-film silver or copper pastes, direct plated copper (DPC), and active metal brazing, each supporting different current densities and adhesion strengths. In practical evaluations, engineers often report current carrying capacities exceeding 50 A/cm on DPC alumina without trace deformation. By contrast, FR4 relies on laminated copper foils, where adhesion and thickness limits can constrain current density under high thermal load.

Accordingly, ceramic metallization trades process simplicity for superior current and thermal endurance.

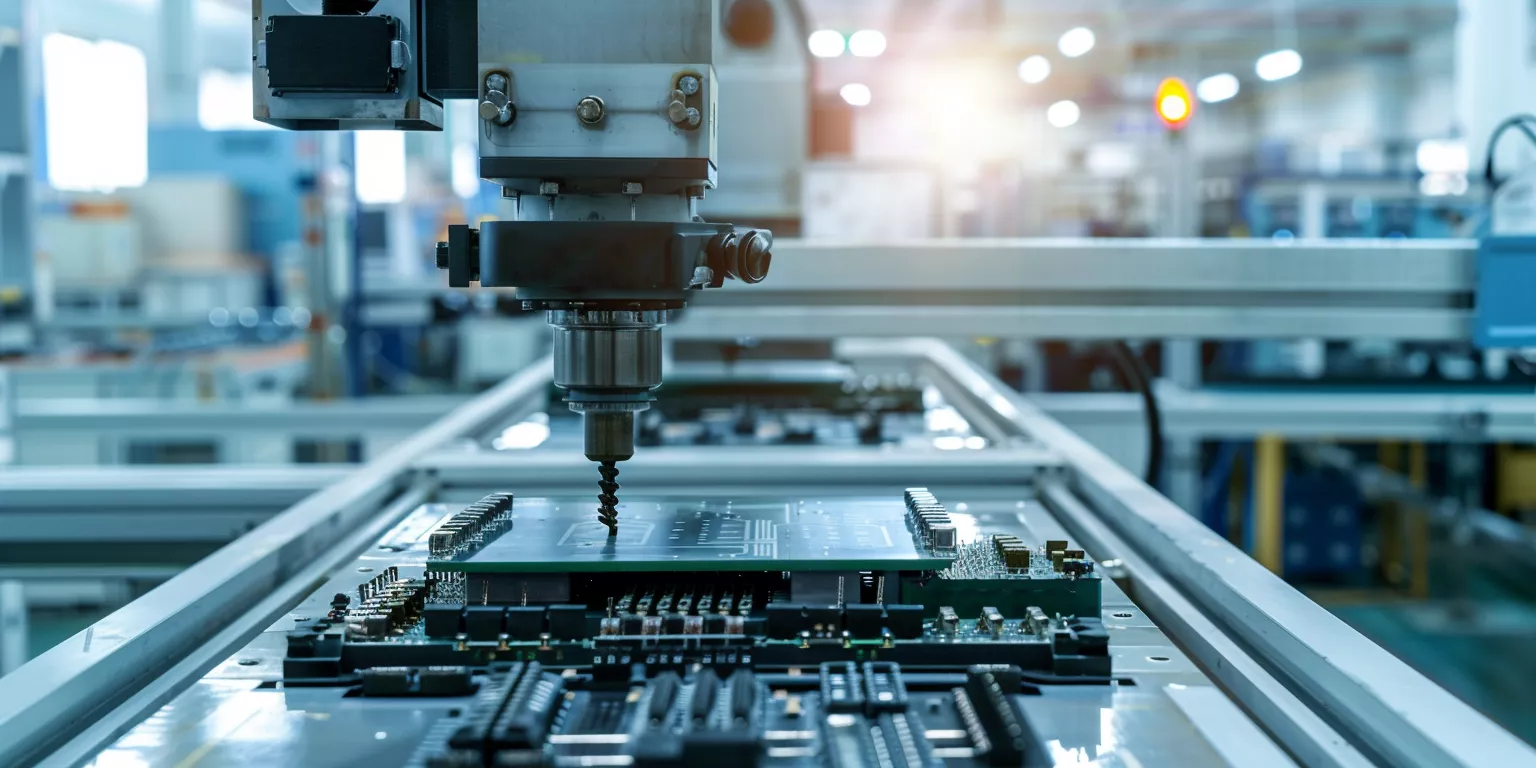

Process yield scalability and manufacturing maturity

Manufacturing maturity affects yield stability and cost predictability across production volumes. Thus, process robustness must be weighed alongside material performance.

FR4 benefits from decades of global PCB manufacturing infrastructure, enabling high yields and rapid iteration across large volumes. Alumina substrate processing, however, involves ceramic sintering, metallization firing, and precision machining, where yield sensitivity increases with feature complexity. Nevertheless, in controlled industrial programs, ceramic yields above 95% are routinely achieved for standardized geometries.

Therefore, alumina substrates favor stable, well-defined designs over frequent layout changes, while FR4 accommodates rapid design iteration.

Summary of Manufacturing Constraints and Design Freedom

| Aspect | Alumina Substrate | FR4 |

|---|---|---|

| Typical Layer Count | 1–2 | ≥10 |

| Minimum Line Width (µm) | 150–200 | <100 |

| Metallization Method | Thick-film, DPC, brazing | Laminated copper |

| Current Density Capability | High | Moderate |

| Manufacturing Maturity | Specialized | Highly mature |

Reliability Performance Across Service Lifecycles

Reliability performance emerges from how materials respond to stress accumulation over time rather than from initial qualification results alone. Therefore, service lifecycle behavior must be examined under repeated thermal, electrical, and environmental exposure. Moreover, alumina substrates and FR4 diverge significantly as operating hours extend and failure mechanisms compound.

Thermal cycling endurance and fatigue accumulation

Thermal cycling endurance reflects how substrates tolerate repeated expansion and contraction without initiating fatigue cracks. Consequently, fatigue accumulation becomes a dominant reliability driver in power electronics operating under variable load.

Alumina substrates routinely withstand 2,000–5,000 thermal cycles between 25 °C and 150 °C with minimal degradation in metallization adhesion. Engineers conducting accelerated life tests often report stable electrical resistance and negligible crack propagation across ceramic interfaces. By contrast, FR4 assemblies frequently exhibit solder joint fatigue and copper pad cracking after 800–1,200 cycles, particularly when operating near or above resin glass transition temperatures.

As a result, alumina substrates significantly extend fatigue life where frequent power cycling is unavoidable.

High temperature and high humidity exposure behavior

Long-term exposure to elevated temperature and humidity reveals material aging pathways that short-term tests may overlook. Therefore, environmental robustness must be evaluated across combined stress conditions.

Alumina ceramics remain chemically inert and dimensionally stable even after 1,000 hours at 85 °C and 85% relative humidity, showing no measurable change in insulation resistance. In contrast, FR4 epoxy systems absorb moisture, which accelerates dielectric degradation and increases leakage currents over time. Field data often indicate insulation resistance reductions of 30–50% in FR4 assemblies following prolonged humid heat exposure.

Consequently, alumina substrates offer superior environmental resilience in harsh industrial and outdoor applications.

Field reliability trends and failure rate divergence

Field reliability data ultimately validate laboratory predictions. Thus, observed failure trends provide critical insight into real-world performance.

In industrial power modules deployed for multi-year service, alumina-based designs consistently demonstrate lower annualized failure rates, particularly in high-temperature duty cycles. Engineers analyzing return data often attribute FR4 failures to cumulative thermal stress, warpage-induced fatigue, and insulation aging rather than single-event overloads. Over extended service intervals, these mechanisms create a widening reliability gap between ceramic and polymer-based substrates.

Therefore, lifecycle reliability increasingly favors alumina substrates as operational demands intensify.

Summary of Lifecycle Reliability Performance

| Reliability Aspect | Alumina Substrate | FR4 |

|---|---|---|

| Thermal Cycle Endurance | 2,000–5,000 cycles | 800–1,200 cycles |

| High-Temperature Stability | Excellent | Limited |

| Humidity Resistance | Inert | Moisture-sensitive |

| Insulation Resistance Retention | High | Degrades over time |

| Long-Term Failure Rate Trend | Low | Increasing |

Application Landscapes Where Differences Become Decisive

Application context ultimately exposes whether substrate trade-offs remain theoretical or translate into measurable performance divergence. Therefore, material differences must be examined where thermal load, electrical stress, and service duration converge. Moreover, alumina substrates and FR4 reveal their true separation only in demanding operational environments rather than benign laboratory conditions.

Power modules and high current assemblies

Power modules concentrate electrical and thermal stress into compact footprints, amplifying substrate-dependent behavior. Consequently, current density and heat extraction efficiency become decisive reliability factors.

In inverter and motor drive platforms, alumina substrates routinely support continuous current densities above 50–70 A/cm with stable temperature gradients. Engineers qualifying IGBT and SiC modules often report junction temperature stabilization within ±5 °C during prolonged full-load operation. By contrast, FR4-based power assemblies frequently exhibit localized copper heating, leading to solder fatigue and trace discoloration after extended high-current exposure.

As a result, alumina substrates enable sustained high-current operation without progressive thermal degradation.

LED lighting and optoelectronic platforms

LED and optoelectronic systems are highly sensitive to junction temperature, which directly affects efficiency and optical stability. Therefore, substrate thermal performance directly influences product lifespan and output consistency.

In high-power LED modules, alumina substrates typically reduce junction temperatures by 15–30 °C compared with FR4 under identical drive conditions. Field evaluations consistently show lumen maintenance improvements exceeding 20% over multi-year operation when ceramic substrates are used. Conversely, FR4-based LED boards often suffer accelerated light output decay and color shift as thermal stress accumulates.

Consequently, alumina substrates play a critical role in preserving optical performance under continuous illumination.

Industrial control and harsh environment electronics

Industrial electronics operate under combined thermal, mechanical, and environmental stress for extended periods. Thus, substrate resilience becomes a determinant of service continuity.

In control modules exposed to ambient temperatures above 70 °C and frequent vibration, alumina substrates maintain dimensional and electrical stability across long service intervals. Engineers monitoring field deployments often observe stable insulation resistance and minimal mechanical drift after 5–10 years of operation. In contrast, FR4 assemblies may exhibit moisture-induced leakage, warpage, and connector misalignment in similarly harsh environments.

Therefore, alumina substrates offer decisive advantages where environmental stress and longevity expectations intersect.

Summary of Application-Specific Performance

| Application Area | Alumina Substrate Advantage | FR4 Limitation |

|---|---|---|

| Power Modules | High current density, stable thermal profile | Localized overheating |

| LED Systems | Lower junction temperature, slower light decay | Accelerated lumen loss |

| Industrial Controls | Environmental robustness, long service life | Moisture and fatigue sensitivity |

| Harsh Environments | Dimensional and insulation stability | Progressive degradation |

Cost Structures and Hidden Economic Tradeoffs

Cost evaluation often begins with material pricing but rarely ends there. Therefore, substrate economics must be examined across the full service lifecycle rather than at initial procurement alone. Moreover, alumina substrates and FR4 distribute cost differently between upfront expenditure and long-term risk exposure.

Initial material and processing cost differences

Upfront cost differences between alumina substrates and FR4 are immediately visible during sourcing. Consequently, early design decisions frequently favor FR4 when budgets are evaluated in isolation.

FR4 substrates benefit from highly optimized global supply chains, resulting in material and fabrication costs that are typically 3–6× lower than ceramic alternatives for comparable board sizes. Standard PCB processes, multilayer stacking, and panelized manufacturing further suppress unit costs at scale. Alumina substrates, by contrast, require ceramic sintering, metallization firing, and precision machining, which elevate initial processing complexity and cost per unit.

As a result, alumina substrates present a higher entry cost that must be justified through downstream performance and reliability gains.

Failure risk cost and field return implications

Hidden economic exposure emerges when failure risk is incorporated into cost models. Therefore, reliability-driven costs often outweigh material price differentials over time.

In power electronics deployments, field failure investigations frequently reveal that substrate-related issues account for 25–40% of warranty returns, particularly those linked to thermal fatigue and insulation degradation. FR4-based assemblies may require early replacement or derating once thermal margins erode, increasing service intervention frequency. Alumina-based designs, however, often demonstrate extended maintenance intervals, reducing cumulative field service and replacement events.

Consequently, failure avoidance and service continuity shift the economic balance toward ceramic substrates in high-duty applications.

Total cost of ownership across product lifetimes

Total cost of ownership integrates procurement, operation, maintenance, and end-of-life considerations. Accordingly, long-term financial performance depends on how reliably a substrate sustains system requirements.

Lifecycle analyses conducted over 5–10 year service periods often show that alumina substrates reduce overall ownership cost despite higher upfront investment. Lower failure incidence, stable electrical performance, and reduced derating requirements contribute to predictable operating expenses. FR4 solutions may remain cost-effective in low-duty or short-life products but exhibit escalating costs as service duration and environmental stress increase.

Therefore, total ownership economics frequently favor alumina substrates where reliability expectations extend beyond initial deployment.

Summary of Economic Tradeoffs

| Cost Dimension | Alumina Substrate | FR4 |

|---|---|---|

| Initial Material Cost | High | Low |

| Manufacturing Complexity | Specialized | Standardized |

| Failure-Related Expense | Low | Moderate to High |

| Maintenance Frequency | Low | Higher |

| Long-Term Ownership Cost | Predictable | Escalating with duty |

When FR4 Remains a Rational Engineering Choice

FR4 continues to serve as a viable substrate option when operating conditions remain within well-controlled thermal and electrical boundaries. Therefore, its advantages emerge most clearly in applications where reliability margins are not continuously stressed.

-

Low to moderate power density systems

FR4 performs reliably when power density remains below 2–3 W/cm², allowing heat to dissipate without forming persistent hotspots. In such conditions, average board temperatures typically stay well below epoxy glass transition thresholds, preserving mechanical integrity. Consequently, many low-power control boards and signal processing modules operate for years on FR4 without measurable degradation. -

Designs requiring high routing density and multilayer complexity

FR4 supports dense multilayer routing, fine line widths, and complex via structures that are difficult or impractical on ceramic substrates. This capability enables compact layouts and functional integration within constrained form factors. As a result, FR4 remains the preferred choice for electronics where electrical complexity outweighs thermal demand. -

Products with limited service life expectations

Short- to medium-life products, typically designed for 3–5 years of operation, may not accumulate sufficient thermal or mechanical fatigue to justify ceramic substrates. In these cases, FR4 offers acceptable reliability while minimizing upfront cost. Therefore, lifecycle alignment between product expectations and material capability favors FR4 in controlled-duty scenarios.

Taken together, FR4 remains rational when operating envelopes are explicitly defined and respected, allowing cost efficiency to coexist with acceptable reliability margins.

When Alumina Substrates Become Technically Inevitable

Alumina substrates become unavoidable once system requirements exceed the safe operating envelope of polymer-based laminates. Accordingly, the decision shifts from cost preference to risk containment and performance assurance.

-

Sustained high power density and elevated operating temperature

When power density consistently exceeds 5 W/cm², thermal gradients intensify beyond what FR4 can redistribute effectively. Under continuous operation above 100–120 °C, epoxy softening and accelerated aging introduce instability that layout optimization cannot eliminate. Consequently, alumina substrates provide the thermal and structural headroom required to maintain stable operation. -

Long service life under cyclic or harsh conditions

Systems designed for 10 years or more of service inevitably accumulate thermal and mechanical fatigue. In such cases, FR4’s viscoelastic behavior allows warpage and solder joint degradation to progress over time. Therefore, alumina substrates become essential to suppress cumulative damage and preserve alignment and electrical integrity. -

High voltage insulation and frequency stability demands

Applications combining elevated voltage with switching frequencies above 50 kHz impose severe dielectric stress. FR4 insulation performance degrades as moisture absorption and temperature rise interact with electric fields. As a result, alumina substrates offer stable dielectric behavior and partial discharge resistance that polymer laminates cannot sustain.

In these scenarios, alumina substrates transition from an optional enhancement to a foundational requirement for system reliability.

Decision Framework for Substrate Selection in Power Electronics

Substrate selection becomes defensible when engineering trade-offs are evaluated systematically rather than intuitively. Accordingly, a structured framework helps align performance targets with material capabilities and long-term risk tolerance.

-

Power density temperature and lifetime convergence

Power density, operating temperature, and target service life form a coupled boundary rather than independent variables. When any two parameters increase, the third rapidly constrains material choice, often eliminating FR4 from consideration. Therefore, mapping these three factors early clarifies whether Alumina Substrate adoption is preventive or mandatory. -

Reliability margin versus cost tolerance balance

Reliability margin represents the buffer between normal operation and failure onset, which narrows as duty severity increases. FR4 may satisfy cost targets initially but erodes margin under prolonged stress, leading to derating or redesign. Consequently, alumina substrates justify higher upfront investment by preserving margin across the full operational envelope. -

Manufacturing maturity and change frequency alignment

Design programs with frequent revisions benefit from FR4’s manufacturing agility and rapid iteration cycles. Conversely, stable architectures with defined geometries favor ceramic substrates, where repeatability and endurance outweigh layout flexibility. Thus, aligning material choice with development cadence reduces friction between engineering intent and production reality.

Taken together, this framework transforms substrate selection from a reactive correction into a proactive reliability strategy.

Closing Perspective on Alumina Substrate and FR4 Choices

Substrate choice ultimately reflects how engineers prioritize stability, longevity, and risk control within a given system context. Consequently, the distinction between FR4 and alumina extends beyond material preference into architectural intent.

-

Substrates as reliability enablers rather than passive carriers

Treating the substrate as a neutral platform often masks early indicators of long-term failure. Thermal gradients, insulation aging, and mechanical strain all converge at the substrate level before symptoms appear elsewhere. Therefore, Alumina Substrate adoption frequently signals a deliberate shift toward reliability-led system design. -

FR4 and alumina as complementary rather than competing options

FR4 remains well-suited for electrically complex, thermally moderate systems with controlled lifetimes. Alumina substrates, by contrast, excel when duty cycles intensify and environmental margins narrow. As a result, effective engineering practice recognizes where each material belongs rather than forcing a universal solution. -

Engineering accountability through material alignment

Material choice embodies accountability for long-term performance commitments. Selecting FR4 in high-stress applications transfers risk into future maintenance and redesign cycles. Consequently, choosing alumina substrates aligns material capability with the reliability promises made to end users.

In closing, aligning substrate selection with system realities transforms material choice into a cornerstone of sustainable power electronic design.

Conclusion

Overall, Alumina Substrate vs FR4 is not a debate about materials alone but a decision about thermal control, electrical stability, and lifecycle risk. In high-duty systems, substrate choice ultimately defines reliability ceilings long before components reach their limits.

If your power, LED, or industrial electronic design is approaching thermal, voltage, or lifetime boundaries, reassessing substrate choice early can prevent costly redesigns later. Align material capability with system intent before constraints become failures.

FAQ

What power density typically pushes designs beyond FR4 capability

FR4 generally remains stable below 2–3 W/cm² under controlled cooling. Once sustained power density exceeds 5 W/cm², localized heating and insulation aging accelerate, making alumina substrates a safer choice.

Does Alumina Substrate always outperform FR4 in thermal management

Alumina substrates provide superior heat spreading and stability at elevated temperatures. However, FR4 can be sufficient in low-power, short-life, or highly complex multilayer designs where thermal stress is limited.

How does substrate choice affect long-term reliability more than components

Components often meet their specifications, while substrates accumulate thermal and mechanical fatigue silently. Alumina Substrate reduces warpage, insulation degradation, and solder fatigue, which are common root causes of field failures.

Is higher upfront cost the main barrier to alumina adoption

Initial cost is higher, yet total ownership cost often favors alumina in high-duty applications. Reduced failures, longer service life, and stable performance offset the initial investment over time.

References: