Alumina Substrate Etching often emerges when reliable surfaces suddenly fail to bond, pattern, or endure service stresses, thereby disrupting downstream manufacturing consistency.

This article consolidates industrial knowledge around Alumina Substrate Etching, addressing material behavior, process pathways, and application outcomes across metallization, microstructuring, bonding, and rework scenarios, while aligning surface engineering decisions with long-term reliability.

Accordingly, the discussion progresses from foundational drivers toward process-aware decision logic, ensuring each subsequent section builds upon established material and engineering context.

Before examining specific methods, it is essential to clarify why Alumina Substrate Etching appears repeatedly across otherwise mature ceramic manufacturing lines, particularly when performance targets tighten.

Why Etching Becomes Necessary in Alumina Substrate Processing

Alumina substrates are inherently stable, electrically insulating, and dimensionally reliable; however, these same attributes often limit surface interaction with metals, coatings, or bonding agents. Consequently, etching is introduced as a controlled intervention rather than a default step, enabling functional interfaces without altering bulk properties.

-

Interface performance limitations become visible at scale

In many production environments, alumina substrates initially perform acceptably without surface modification. Nevertheless, as operating temperatures exceed 150–300 thermal cycles or metallized layers exceed 10–20 μm thickness, adhesion variability becomes evident. For instance, engineers frequently observe peel strength reductions exceeding 25% after repeated thermal cycling, indicating insufficient surface engagement. -

Geometric and functional integration demands increase

As circuit densities rise and mechanical tolerances tighten, flat alumina surfaces no longer provide adequate anchoring for deposited films or bonded structures. Specifically, micro-scale surface features on the order of 1–5 μm become necessary to stabilize interfaces without compromising electrical insulation. Etching offers a pathway to introduce such features in a controlled manner. -

Manufacturing recovery and lifecycle extension require intervention

During rework or failure analysis, residual metallization or contamination layers must often be removed without damaging the ceramic base. In these cases, selective etching becomes the only viable option to restore substrate usability while maintaining dimensional integrity within ±0.05 mm.

Consequently, etching transitions from an optional enhancement to a strategic tool that reconciles material stability with functional adaptability, thereby setting the stage for deeper exploration of alumina surface behavior and processing pathways in the sections that follow.

Material Structure of Alumina Substrates and Etching Responsiveness

Before any etching pathway is evaluated, the intrinsic material structure of alumina substrates establishes clear boundaries on how surfaces respond to chemical or physical modification. Consequently, understanding microstructural behavior is essential for predicting etching outcomes and avoiding unintended degradation.

-

Polycrystalline grain structure governs local etching variability

Alumina substrates are typically polycrystalline, composed of tightly packed grains ranging from 1 to 10 μm depending on sintering conditions. As a result, etching reactions rarely proceed uniformly across the surface; instead, grain boundaries exhibit higher chemical activity than grain interiors. In practice, engineers often notice preferential material removal along these boundaries, leading to micro-topographical contrast rather than smooth planar recession. This behavior explains why alumina etching enhances surface engagement without producing deep, silicon-like features. -

Purity level directly influences chemical stability and reaction window

Commercial alumina substrates commonly fall within 96% to 99% Al₂O₃ purity, with the remaining fraction consisting of glassy phases or sintering aids. These secondary phases soften or dissolve earlier during chemical exposure, accelerating localized material removal. Conversely, higher-purity substrates show slower etch kinetics and narrower process windows, requiring stricter control of temperature and exposure time. Therefore, identical etching recipes can yield substantially different surface states across purity grades. -

Surface energy and porosity define etching responsiveness rather than bulk hardness

Although alumina exhibits high hardness values exceeding 1500 HV, etching behavior correlates more strongly with surface energy distribution and closed porosity than with bulk mechanical strength. Minor variations in surface finish or residual porosity can alter etch rates by 15–30% under otherwise identical conditions. Consequently, surface preparation steps prior to etching often determine final reproducibility more than the etching medium itself. This insight shifts engineering focus from aggressiveness to consistency.

Taken together, alumina substrate etching is fundamentally constrained by microstructural realities, which means subsequent process selection must respect material-driven limits rather than relying on generalized ceramic assumptions.

Chemical Etching Mechanisms Applicable to Alumina Substrates

Chemical etching represents the most frequently evaluated pathway when controlled surface modification of alumina is required. Moreover, it offers predictable interaction with microstructural features while preserving bulk integrity, provided that reaction parameters remain within defined boundaries. Accordingly, understanding chemical mechanisms becomes essential before considering hybrid or physical alternatives.

Acid-Based Etching Systems and Their Reaction Pathways

Chemical interaction between alumina and acidic media occurs primarily through surface hydroxyl groups rather than bulk dissolution. Consequently, etching progresses slowly and selectively, with reaction rates typically below 0.1–0.5 μm/min under controlled laboratory conditions.

In industrial practice, phosphoric-acid-based systems operated at elevated temperatures between 180–280 °C are most frequently reported. These systems preferentially attack glassy grain-boundary phases, producing measurable surface roughness increases from Ra 0.2 μm to 0.8–1.5 μm without catastrophic material loss. During pilot trials, engineers often observe that extending exposure beyond 10–15 minutes yields diminishing roughness gains while increasing defect probability. This balance highlights why alumina etching relies on boundary activation rather than aggressive bulk removal.

Therefore, acid-based etching should be viewed as a surface activation mechanism rather than a material removal strategy, particularly when dimensional preservation is critical.

Selectivity Control and Etch Rate Stability

Etch selectivity in alumina substrates is governed by phase distribution rather than crystallographic orientation. As a result, substrates with 96% purity often exhibit etch rates 20–35% higher than 99% purity variants under identical conditions.

During scaled processing, maintaining stable temperature gradients within ±5 °C proves essential for uniform surface evolution. In one production setting, uneven heating across a batch introduced roughness variation exceeding ±0.3 μm, directly impacting metallization adhesion consistency. Engineers therefore emphasize thermal uniformity and agitation control as primary stability levers. Chemical concentration alone rarely compensates for thermal inconsistency in alumina etching.

Consequently, repeatable etching outcomes depend more on process environment control than on increasing chemical aggressiveness.

Chemical Etching Risks Including Microcrack Initiation

Although chemical etching is comparatively gentle, excessive exposure can initiate microstructural damage. Specifically, prolonged boundary dissolution weakens grain interlocking, increasing the probability of microcrack formation under subsequent thermal cycling.

Empirical observations indicate that substrates exposed beyond 25–30 minutes in high-temperature acid environments show flexural strength reductions of 8–15%. These changes often remain invisible under optical inspection yet manifest during thermal shock testing above ΔT 200 °C. Engineers encountering unexpected fracture frequently trace failures back to overly extended etching steps. This experience reinforces the importance of conservative exposure windows.

Thus, chemical etching must be bounded by mechanical reliability considerations rather than surface appearance alone.

Summary of Chemical Etching Characteristics for Alumina Substrates

| Parameter | Typical Range |

|---|---|

| Etch rate (μm/min) | 0.1–0.5 |

| Operating temperature (°C) | 180–280 |

| Surface roughness increase Ra (μm) | 0.6–1.3 |

| Strength reduction risk (%) | 0–15 |

| Recommended exposure time (min) | 5–15 |

| Purity sensitivity | High |

| Dimensional impact | Minimal when controlled |

Physical and Hybrid Etching Approaches for Alumina Substrates

While chemical etching addresses surface activation through controlled reactions, physical and hybrid approaches are adopted when spatial selectivity or pattern definition becomes critical. Moreover, these methods enable localized modification without immersing the entire substrate in reactive environments. Accordingly, engineers evaluate physical and hybrid etching as complementary tools rather than direct replacements for chemical processes.

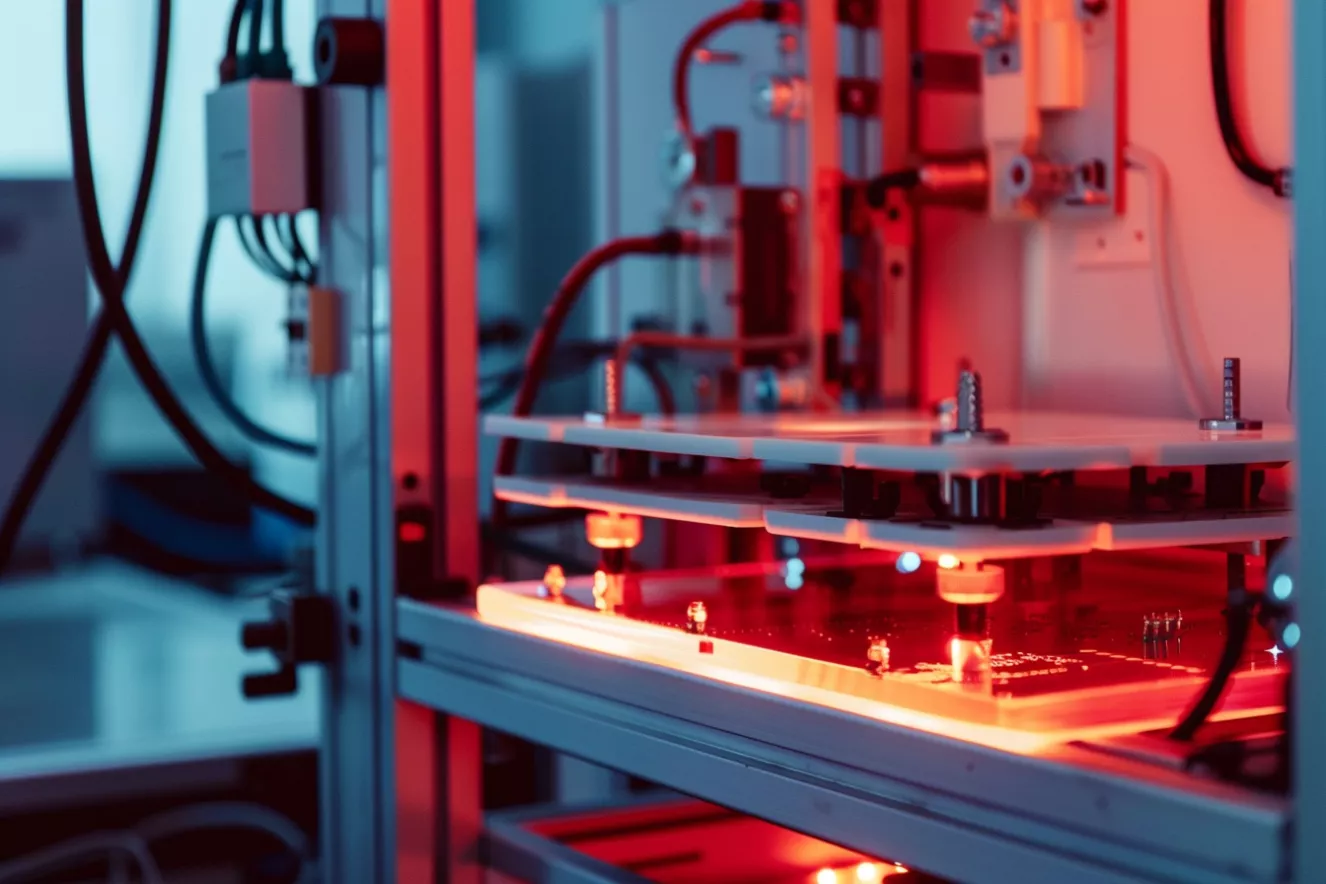

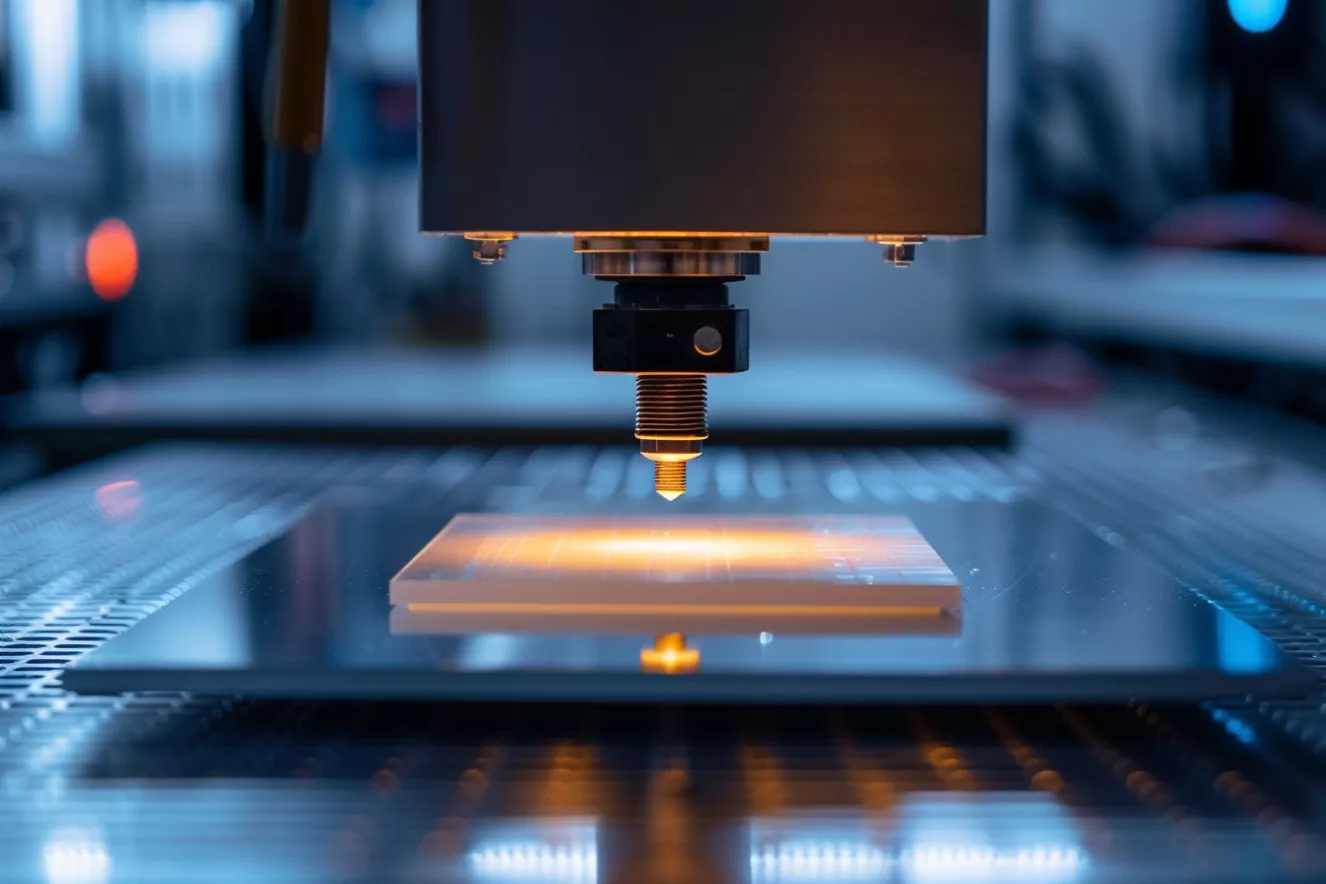

Laser-Based Surface Texturing on Alumina Substrates

Laser-based texturing modifies alumina surfaces through localized thermal and ablation effects rather than chemical dissolution. Consequently, material interaction is confined to precisely defined regions, often within 10–50 μm spot diameters.

In industrial settings, pulsed laser systems operating between 10–100 ns pulse widths are commonly applied to generate microgrooves or anchor patterns. Engineers report achievable feature depths of 2–20 μm, depending on energy density and scan speed. However, improper parameter selection introduces heat-affected zones extending 3–8 μm below the surface, which may alter local dielectric behavior. This sensitivity explains why laser etching demands tight parameter envelopes rather than broad process margins.

Therefore, laser texturing is most effective when feature placement outweighs concerns about subsurface thermal alteration.

Abrasive and Plasma-Assisted Methods

Abrasive-based techniques, including micro-blasting and controlled grit projection, rely on mechanical impact rather than thermal or chemical interaction. As a result, surface roughness increases rapidly, often reaching Ra 1.5–3.5 μm within seconds.

Plasma-assisted treatments, by contrast, alter surface chemistry and energy without significant material removal. In practice, plasma exposure modifies only the upper 50–200 nm of the surface while increasing wettability by 30–60%. Engineers often combine light abrasive texturing with plasma activation to balance anchoring depth and cleanliness. This hybrid sequencing reduces particle embedment risks commonly observed in standalone abrasive processing.

Accordingly, abrasive and plasma methods are selected when speed and surface activation outweigh the need for fine geometric control.

Comparative Process Windows Between Chemical and Physical Etching

Physical and chemical etching differ fundamentally in how process windows are defined. Chemical systems rely on temperature, concentration, and time, whereas physical methods depend on energy density, exposure duration, and tool stability.

During pilot evaluations, engineers frequently observe that chemical etching maintains dimensional deviation below ±0.02 mm, while aggressive physical methods may exceed ±0.05 mm without masking strategies. Nevertheless, physical etching achieves localized modification unattainable through immersion processes. This contrast drives hybrid adoption when both dimensional control and localized roughening are required.

Consequently, comparative selection hinges on whether uniformity or spatial precision represents the dominant design constraint.

Summary of Physical and Hybrid Etching Characteristics

| Approach | Typical Feature Depth (μm) | Surface Roughness Ra (μm) | Thermal Impact Zone (μm) | Spatial Selectivity | Dimensional Stability |

|---|---|---|---|---|---|

| Laser texturing | 2–20 | 0.8–2.0 | 3–8 | High | Moderate |

| Abrasive micro-blasting | 5–30 | 1.5–3.5 | None | Low | Low |

| Plasma-assisted treatment | <0.2 | <0.5 | None | Moderate | High |

| Hybrid abrasive + plasma | 3–15 | 1.0–2.5 | None | Moderate | Moderate |

Etched Alumina Surfaces for Metallization and Film Deposition

Etched alumina surfaces play a decisive role in metallization and film deposition performance, particularly where electrical reliability and thermal endurance intersect. Moreover, surface modification directly influences interfacial adhesion mechanisms that cannot be compensated by deposition parameters alone. Accordingly, etching is treated as a prerequisite step rather than a corrective measure in advanced alumina-based assemblies.

Etching-Induced Roughness and Metallization Adhesion Strength

Surface roughness generated through etching establishes mechanical interlocking between alumina substrates and deposited metallic layers. Consequently, adhesion improvements arise from geometric anchoring rather than chemical bonding alone.

In controlled studies and factory trials, alumina substrates etched to Ra 0.8–1.5 μm demonstrate adhesion strength increases of 35–70% compared with unetched counterparts. Engineers frequently report that peel strengths stabilize above 12–18 N/mm for Mo-Mn or sputtered metal systems when roughness falls within this window. However, roughness exceeding 2.5 μm often introduces stress concentration points that reduce long-term stability. This experience highlights that adhesion gains plateau beyond an optimal roughness range.

Therefore, etching parameters must target controlled micro-topography rather than maximal surface aggression.

Compatibility with Mo-Mn and Thin-Film Metallization Systems

Mo-Mn metallization1 remains widely used for alumina substrates due to its thermal compatibility and proven reliability. Consequently, etched surfaces must support uniform paste wetting and sintering behavior without trapping residual contaminants.

During pilot production, engineers often observe that etched alumina improves Mo-Mn layer continuity by reducing localized delamination after firing at 1400–1500 °C. Similarly, in thin-film sputtering systems, etched substrates exhibit reduced pinhole density by 20–40%, attributed to improved nucleation uniformity. These outcomes demonstrate that etching influences deposition morphology as much as adhesion strength.

Thus, metallization compatibility depends on how etching modifies both surface energy and micro-scale geometry.

Thermal Cycling Reliability of Etched and Metallized Alumina Substrates

Thermal cycling performance remains the decisive qualification metric for metallized alumina substrates. Consequently, etched interfaces must maintain integrity under repeated expansion and contraction cycles.

In accelerated testing, etched and metallized alumina substrates consistently withstand 500–1000 thermal cycles between −40 °C and 150 °C with less than 5% adhesion degradation. By contrast, non-etched substrates often exhibit early edge lifting or microcrack initiation after 200–300 cycles. Engineers conducting failure analysis frequently trace these differences to interfacial stress redistribution enabled by etched surface features. This correlation reinforces etching as a reliability enabler rather than a cosmetic enhancement.

Accordingly, thermal endurance validation should always consider surface preparation history alongside metallization design.

Summary of Etched Alumina Performance in Metallization and Film Deposition

| Parameter | Unetched Alumina | Etched Alumina |

|---|---|---|

| Surface roughness Ra (μm) | 0.1–0.3 | 0.8–1.5 |

| Metallization adhesion strength (N/mm) | 6–10 | 12–18 |

| Thin-film defect density (%) | Baseline | −20 to −40 |

| Thermal cycle endurance (cycles) | 200–300 | 500–1000 |

| Delamination risk | Moderate | Low |

| Process reproducibility | Limited | High |

Microstructuring Alumina Substrates Through Etching

Microstructuring through etching addresses application scenarios where alumina substrates must perform beyond planar support functions. Moreover, controlled surface features enable functional integration in sensing, fluid handling, and interface management without altering bulk ceramic properties. Accordingly, etching-based microstructuring is evaluated as a surface-level engineering solution rather than a bulk material transformation.

Formation of Microgrooves and Controlled Surface Features

Etching enables the formation of shallow microgrooves and textured regions that guide mechanical, thermal, or fluid interactions. Consequently, feature generation remains constrained to surface layers while preserving structural rigidity.

In practical implementations, chemical and hybrid etching processes yield microgroove depths between 1–8 μm and lateral feature widths of 10–50 μm, depending on mask design and exposure control. Engineers working with sensor housings often report improved signal stability when surface textures fall below 5 μm, minimizing stress concentration. Conversely, attempts to exceed 10 μm depth frequently lead to irregular profiles due to grain-boundary dominance. This limitation underscores the surface-oriented nature of alumina microstructuring.

Therefore, etched microfeatures are best applied for guidance and anchoring rather than volumetric shaping.

Etching Limitations Imposed by Alumina Brittleness

Alumina’s intrinsic brittleness imposes strict limits on how aggressively microstructuring can be pursued. As a result, etching cannot replicate deep, high-aspect-ratio features common in silicon processing.

Field experience shows that when etched feature depth exceeds 8–12 μm, localized stress accumulation increases crack initiation probability by 20–30% during mechanical or thermal loading. Engineers evaluating failed microstructured substrates often observe crack paths following etched boundary regions rather than bulk grain interiors. This behavior clarifies why alumina microstructuring must remain shallow and conservative.

Accordingly, successful designs emphasize distributed microtextures instead of isolated deep cavities.

Functional Integration in Microfluidic and Sensor Interfaces

Microstructured alumina substrates are increasingly adopted in sensor and microfluidic interfaces where chemical stability and insulation are critical. Consequently, etched textures serve as alignment aids, flow stabilizers, or bonding anchors.

In microfluidic testing environments, etched surface patterns improve fluid wetting consistency by 15–25%, reducing flow instability at low Reynolds numbers. Sensor developers similarly report improved repeatability when etched regions localize active elements without introducing electrical leakage paths. These outcomes demonstrate that microstructuring enhances functional integration without compromising alumina’s inherent insulation.

Thus, etching-based microstructuring aligns well with precision-oriented applications rather than load-bearing roles.

Summary of Microstructuring Capabilities via Alumina Etching

| Aspect | Typical Range |

|---|---|

| Microfeature depth (μm) | 1–8 |

| Lateral feature width (μm) | 10–50 |

| Crack risk threshold depth (μm) | 8–12 |

| Wetting consistency improvement (%) | 15–25 |

| Electrical insulation impact | None |

| Structural integrity retention | High |

Etching in Rework Cleaning and Failure Analysis Contexts

Etching assumes a different function in rework and failure analysis, where the objective shifts from surface enhancement to controlled material removal. Moreover, these contexts demand extreme selectivity, as the alumina substrate must remain structurally intact while unwanted layers are eliminated. Accordingly, etching is applied as a precision recovery tool rather than a surface optimization step.

Selective Removal of Residual Metallization Without Substrate Damage

In rework scenarios, etching is often used to remove residual metallization layers while preserving the underlying alumina substrate. Consequently, process windows are deliberately narrow to avoid unintended ceramic attack.

During controlled rework operations, engineers typically target metal layer removal rates of 0.2–0.6 μm/min, ensuring that exposure time remains below 5–8 minutes. Practical experience shows that exceeding this window increases surface roughness beyond Ra 2.0 μm, which complicates subsequent re-metallization. Successful rework therefore relies on time-limited exposure rather than aggressive chemistry.

Thus, selective etching enables substrate reuse while maintaining dimensional and surface consistency.

Surface Artifacts Introduced by Improper Etching Practices

Improper etching conditions frequently introduce artifacts that obscure failure analysis rather than clarify it. As a result, analysts must distinguish between process-induced damage and original failure signatures.

In laboratory investigations, over-etched alumina surfaces exhibit boundary pitting and microvoid formation measurable at 1–3 μm depth. Engineers conducting root-cause analysis often report misinterpretation when these artifacts mimic crack initiation sites. Such false indicators can lead to incorrect conclusions regarding metallization or thermal fatigue failures.

Accordingly, controlled etching protocols are essential to preserve diagnostic clarity during failure analysis.

Etching as a Diagnostic Preparation Step

Beyond material removal, etching is frequently employed to expose hidden interfaces for inspection. Consequently, it supports microscopy and cross-sectional evaluation without mechanical polishing.

In failure analysis workflows, light etching enhances interface visibility by increasing contrast between alumina grains and residual layers. Analysts report improved crack path identification accuracy by 20–30% when etched preparation replaces dry polishing. This approach minimizes mechanical smearing while preserving microstructural authenticity.

Therefore, etching functions as an enabling step that improves analytical resolution rather than altering failure mechanisms.

Summary of Etching Roles in Rework and Failure Analysis

| Application Context | Primary Objective | Typical Control Window |

|---|---|---|

| Metallization rework | Remove metal layers | 0.2–0.6 μm/min |

| Exposure duration (min) | Prevent substrate attack | 5–8 |

| Artifact depth (μm) | Diagnostic risk threshold | 1–3 |

| Roughness after rework Ra (μm) | Re-metallization limit | ≤2.0 |

| Diagnostic accuracy improvement (%) | Interface exposure | 20–30 |

| Substrate reuse feasibility | Post-rework | High |

Etched Alumina Surfaces and Structural Bonding Performance

Structural bonding introduces a different performance lens for etched alumina surfaces, as mechanical load transfer and environmental durability become primary concerns. Moreover, bonding reliability depends less on visual surface condition and more on how etching modifies interfacial stress distribution2. Accordingly, etching is evaluated as a means to stabilize bonded joints3 rather than merely increase initial bond strength.

Correlation Between Surface Roughness and Bond Strength

Etched surface roughness directly influences mechanical interlocking at the bond interface. Consequently, bond strength improvements arise when surface features promote load sharing without introducing stress concentration.

In adhesive bonding trials, alumina substrates etched to Ra 0.6–1.2 μm consistently exhibit shear strength increases of 25–45% compared with polished surfaces. Engineers frequently observe that roughness below 0.4 μm results in adhesive-dominated failure, whereas roughness above 1.8 μm initiates cohesive fracture within the ceramic near etched valleys. This observation confirms that optimal bonding relies on balanced roughness rather than maximum texturing.

Therefore, roughness control functions as a structural design variable rather than a secondary surface attribute.

Long-Term Stability of Bonded Interfaces on Etched Alumina

Bonded alumina assemblies are often subjected to prolonged thermal and environmental exposure. As a result, etched interfaces must retain integrity beyond initial qualification tests.

Accelerated aging studies indicate that etched alumina joints maintain over 85–90% of initial shear strength after 1,000 hours at 125 °C, while unetched counterparts drop below 70% within the same period. Engineers evaluating field returns frequently link premature debonding to insufficient surface activation rather than adhesive formulation. These findings emphasize the role of etched microfeatures in mitigating interfacial creep and relaxation.

Accordingly, etching contributes to bond longevity by redistributing interfacial stresses under sustained loading.

Compatibility with Brazing and Coating-Based Bonding Systems

Beyond adhesives, etched alumina surfaces are also used in brazing and coating-assisted bonding systems. Consequently, surface condition affects wetting behavior and joint uniformity.

In brazed assemblies, etched alumina substrates show wetting angle reductions of 15–25%, improving filler metal flow and joint continuity. Coating-based bonding systems similarly benefit from etched surfaces through improved coating adhesion and reduced delamination during thermal cycling. Engineers often note that etched substrates exhibit fewer interfacial voids during post-bond inspection.

Thus, etching enhances compatibility across multiple structural bonding methodologies without altering base material composition.

Summary of Structural Bonding Performance on Etched Alumina

| Parameter | Unetched Alumina | Etched Alumina |

|---|---|---|

| Surface roughness Ra (μm) | 0.1–0.3 | 0.6–1.2 |

| Shear strength increase (%) | Baseline | +25–45 |

| Strength retention after aging (%) | 65–70 | 85–90 |

| Wetting angle reduction (%) | Minimal | 15–25 |

| Interfacial void occurrence | Moderate | Low |

| Long-term bond stability | Limited | High |

Process Control Parameters in Alumina Substrate Etching

Process control defines whether alumina substrate etching remains a repeatable surface-engineering step or devolves into an unpredictable risk factor. Moreover, unlike bulk ceramic processing, etching outcomes depend on tightly coupled variables that amplify small deviations. Accordingly, engineers treat parameter discipline as the primary determinant of yield and reliability rather than chemical selection alone.

Temperature Time and Concentration Interdependence

Temperature, exposure time, and chemical concentration interact nonlinearly during alumina substrate etching. Consequently, adjusting one parameter in isolation rarely produces predictable results.

In controlled etching environments, increasing temperature by 10 °C can accelerate effective etch rates by 20–35%, even when concentration remains unchanged. Engineers often report that compensating with shorter exposure times introduces surface non-uniformity exceeding ±0.25 μm Ra across a single substrate. Conversely, lowering concentration while extending time tends to preserve uniformity but increases sensitivity to boundary-phase dissolution. These observations confirm that stable etching relies on balanced parameter coupling rather than linear scaling.

Therefore, parameter optimization must be performed as a system-level exercise rather than through incremental adjustments.

Batch Consistency and Scale-Up Constraints

Maintaining batch-to-batch consistency becomes increasingly challenging as etching scales from laboratory samples to production lots. As a result, uniform heat distribution and chemical refresh rates dominate scale-up feasibility.

In pilot production lines, temperature gradients exceeding ±4 °C across a batch have been shown to generate roughness deviations of 30–40%, directly impacting metallization adhesion yields. Engineers frequently mitigate this risk by limiting batch sizes and implementing staged immersion rather than single-vessel loading. Experience shows that aggressive batch consolidation often increases scrap rates instead of reducing cost.

Accordingly, scale-up strategies prioritize thermal uniformity and controlled throughput over volumetric efficiency.

Monitoring Surface Evolution During Etching

Real-time or staged monitoring provides critical feedback during alumina substrate etching. Consequently, surface characterization becomes an integral part of process control rather than a post-process verification step.

In practice, intermittent roughness measurement after 2–3 minute intervals allows engineers to detect boundary over-activation before structural degradation occurs. Facilities implementing such checkpoints report surface consistency improvements of 20–25% across production runs. This proactive approach reduces reliance on destructive testing while preserving mechanical integrity.

Thus, monitoring transforms etching from a fixed recipe into a controlled progression aligned with material response.

Summary of Critical Process Control Parameters

| Parameter Category | Typical Control Range |

|---|---|

| Temperature stability (°C) | ±3–5 |

| Exposure time window (min) | 5–15 |

| Etch rate variability (%) | ≤30 |

| Acceptable roughness deviation Ra (μm) | ±0.2–0.3 |

| Batch temperature gradient (°C) | ≤4 |

| Yield impact from control loss (%) | 15–40 |

Common Engineering Failures Linked to Improper Etching

Improper etching introduces failure mechanisms that often remain hidden until late-stage testing or field operation. Consequently, these failures are frequently misattributed to metallization, bonding materials, or operating conditions rather than surface preparation errors.

-

Excessive surface roughening leading to premature fracture

Over-etching increases micro-topographical depth beyond structurally tolerant limits, particularly when surface valleys exceed 8–10 μm. In operational environments, such features concentrate stress and accelerate crack initiation during thermal cycling or mechanical loading. Engineers routinely encounter fracture paths that trace etched regions rather than bulk grain interiors, revealing surface preparation as the root cause. -

Non-uniform etching causing interfacial instability

Uneven temperature distribution or inconsistent exposure time produces roughness variation across a single substrate. This non-uniformity results in localized adhesion strength differences exceeding 30%, which promote edge lifting or partial delamination under service conditions. Such failures often appear sporadic, yet they originate from predictable process imbalance. -

Chemical residue retention and contamination-related defects

Inadequate post-etch cleaning leaves residual ions or reaction byproducts embedded along grain boundaries. These residues can increase leakage currents by 10–20% or interfere with metallization wetting during subsequent processing. Field analysis frequently links unexpected electrical drift to incomplete etchant removal rather than material defects.

Consequently, recognizing these failure patterns reinforces the need for disciplined etching control and provides a clear transition toward defining when etching should be avoided altogether in alumina substrate design.

Selecting an Etching Strategy Based on Application Demands

Selecting an appropriate etching strategy requires aligning surface modification objectives with real operating constraints rather than applying a uniform process across applications. Moreover, etching decisions influence not only surface condition but also downstream reliability, yield stability, and lifecycle cost. Accordingly, engineers evaluate etching strategies through application-driven performance priorities instead of isolated process capability.

Power Electronics and High Thermal Load Systems

Power electronic assemblies impose simultaneous electrical insulation and thermal cycling demands on alumina substrates. Consequently, etching strategies must enhance metallization adhesion without weakening structural integrity.

In these systems, controlled chemical etching producing Ra 0.8–1.3 μm consistently supports stable metallization under 500–1,000 thermal cycles. Engineers working on IGBT modules often report that deeper texturing increases crack risk near solder joints, especially above ΔT 200 °C. This experience reinforces preference for uniform chemical etching over aggressive physical methods in high thermal load environments.

Therefore, conservative surface activation remains the dominant strategy where thermal endurance defines system success.

Sensors and Precision Instrumentation

Sensors and precision instrumentation prioritize signal stability, dimensional fidelity, and surface cleanliness. As a result, etching strategies emphasize subtle surface modification rather than pronounced roughening.

In sensor housings and signal substrates, light etching within Ra 0.4–0.8 μm improves bonding repeatability while maintaining tight tolerances below ±0.02 mm. Engineers frequently note that plasma-assisted or hybrid etching reduces contamination-related drift by 15–25% compared with abrasive methods. Such outcomes highlight the importance of surface chemistry control over mechanical texturing.

Accordingly, precision applications favor etching methods that preserve geometry while enhancing interface consistency.

Structural and Assembly-Oriented Applications

Structural assemblies subject alumina substrates to mechanical load transfer and environmental exposure. Consequently, etching strategies must balance anchoring strength with crack resistance.

In bonded or brazed assemblies, hybrid etching approaches combining mild chemical activation with limited physical texturing yield shear strength improvements of 30–45%. Engineers evaluating field returns often observe that assemblies processed with overly aggressive etching exhibit early microcrack propagation under vibration. This observation underscores the need for distributed microfeatures rather than isolated deep textures.

Thus, assembly-driven designs benefit from moderate, evenly distributed surface modification strategies.

Summary of Etching Strategy Selection by Application

| Application Category | Preferred Etching Approach | Target Roughness Ra (μm) | Primary Performance Driver |

|---|---|---|---|

| Power electronics | Chemical etching | 0.8–1.3 | Thermal cycling reliability |

| Precision sensors | Plasma or light chemical | 0.4–0.8 | Signal stability |

| Structural assemblies | Hybrid chemical + physical | 0.6–1.2 | Load transfer durability |

| Rework and analysis | Selective chemical | ≤0.6 | Substrate preservation |

| Microstructured interfaces | Chemical or laser-assisted | 1–8 μm features | Functional integration |

When Etching Should Be Avoided in Alumina Substrate Design

Etching is not universally beneficial in alumina substrate design, particularly when surface modification introduces more risk than functional gain. Consequently, recognizing scenarios where etching should be deliberately excluded is as important as mastering its application.

-

Applications dominated by bulk mechanical strength requirements

In load-bearing or impact-sensitive designs, etched surface features may act as crack initiation sites under mechanical stress. Engineers have documented flexural strength reductions of 10–20% in aggressively etched substrates subjected to vibration or shock loading. In such cases, preserving a polished or minimally processed surface provides superior structural reliability. -

High-precision dimensional tolerance constraints

Designs requiring dimensional tolerances tighter than ±0.02 mm often cannot accommodate even shallow surface recession. Minor etching-induced material loss can accumulate across multiple surfaces, complicating assembly alignment and calibration. For ultra-precision components, surface stability outweighs potential adhesion benefits. -

Electrically sensitive environments with minimal interface demands

In applications where alumina functions solely as an electrical insulator without bonded or metallized interfaces, etching offers limited value. Introducing surface roughness in such contexts may increase contamination retention or surface leakage risks by 10–15% under humid conditions. Avoiding etching in these designs reduces unnecessary processing complexity.

Accordingly, strategic restraint in applying etching ensures that alumina substrate design remains aligned with functional priorities rather than procedural convention.

Custom Etched Alumina Substrates by ADCERAX

Custom etching requires coordination between material behavior, surface objectives, and downstream application constraints. Accordingly, ADCERAX positions etching as an integrated engineering service rather than an isolated surface treatment.

-

Engineering-led etching design based on application intent

ADCERAX begins each custom etching project by clarifying how the etched alumina substrate will function within the final system, whether for metallization, bonding, microstructuring, or rework. Engineers evaluate substrate purity, thickness, and flatness alongside target roughness or feature depth to establish a realistic etching window. This front-loaded engineering alignment reduces trial iterations by up to 30–40% compared with recipe-driven approaches. -

Flexible process selection and parameter optimization

Depending on performance priorities, ADCERAX applies chemical, physical, or hybrid etching routes under tightly controlled conditions. Surface roughness targets typically range from Ra 0.4 to 1.5 μm, while microfeature depths remain within material-safe limits. Parameter tuning emphasizes repeatability and batch consistency rather than maximum material removal. -

One-stop support from drawing review to delivery

Beyond etching execution, ADCERAX supports drawing verification, tolerance review, surface inspection, and compatibility assessment for subsequent metallization or bonding steps. Standard alumina substrates can ship within 24 hours, while custom-etched substrates follow accelerated lead times aligned with pilot and production schedules. This integrated workflow simplifies supplier coordination for OEM and equipment manufacturers.

Consequently, ADCERAX enables custom etched alumina substrates to transition smoothly from engineering validation to stable production without compromising material integrity or delivery efficiency.

Closing Perspective on Etching as a Surface Engineering Tool

Etching occupies a precise position within alumina substrate engineering, offering targeted surface modification without redefining the ceramic’s fundamental role. Accordingly, its value emerges when applied with restraint, clarity of purpose, and respect for material boundaries.

-

Etching functions as an interface enabler rather than a universal solution

Etching improves interaction at interfaces where adhesion, bonding, or functional integration is required, yet it does not enhance bulk alumina properties such as stiffness or fracture toughness. Engineers consistently find that surface modification delivers the greatest benefit when paired with clearly defined downstream requirements. This perspective prevents etching from being misapplied as a corrective measure for unrelated design limitations. -

Material-aware application determines long-term reliability

Successful etching strategies account for alumina’s grain structure, purity, and brittleness before any process parameters are selected. Ignoring these constraints often leads to hidden reliability risks that surface only during extended operation. Material-aware application ensures that surface gains do not translate into structural compromises. -

Process discipline outweighs procedural complexity

Reliable outcomes depend more on disciplined control of exposure, temperature, and uniformity than on sophisticated equipment or aggressive chemistries. In production environments, simpler and well-controlled etching routes frequently outperform complex, loosely managed alternatives. Consistency, rather than intensity, defines sustainable surface engineering practice.

Consequently, etching remains most effective when treated as a deliberate surface engineering tool, applied only where it meaningfully supports functional performance and system reliability.

Conclusion

Alumina Substrate Etching enables controlled surface functionality when material behavior, process limits, and application demands are aligned with engineering intent rather than routine practice.

If your application requires controlled Alumina Substrate Etching for metallization, bonding, microstructuring, or rework, ADCERAX provides engineering-led customization from drawing review to stable batch delivery. Contact the ADCERAX technical team to evaluate feasibility before committing to production.

FAQ

What surface roughness range is typically recommended for Alumina Substrate Etching?

In most industrial applications, a surface roughness of Ra 0.6–1.5 μm balances adhesion improvement and structural safety. Values outside this range should be justified by application-specific testing.

Can Alumina Substrate Etching affect electrical insulation performance?

When properly controlled, etching does not degrade electrical insulation. However, excessive roughness or residual contamination may increase surface leakage risk under high humidity.

Is Alumina Substrate Etching suitable for high-purity substrates?

Yes, but higher-purity alumina exhibits slower etch kinetics and narrower process windows. Parameter control becomes more critical compared with 96% alumina grades.

Can etched alumina substrates be reliably re-metallized after rework?

Selective etching with limited exposure time allows successful re-metallization, provided post-etch cleaning is thorough and surface roughness remains below Ra 2.0 μm.

References:

-

Explore this link to understand how Mo-Mn metallization enhances thermal compatibility and reliability in electronic applications. ↩

-

Understanding this concept is crucial for improving bonding techniques and ensuring long-lasting structural integrity. ↩

-

Learn how etching techniques can improve the stability and durability of bonded joints in structural engineering for better long-term performance. ↩