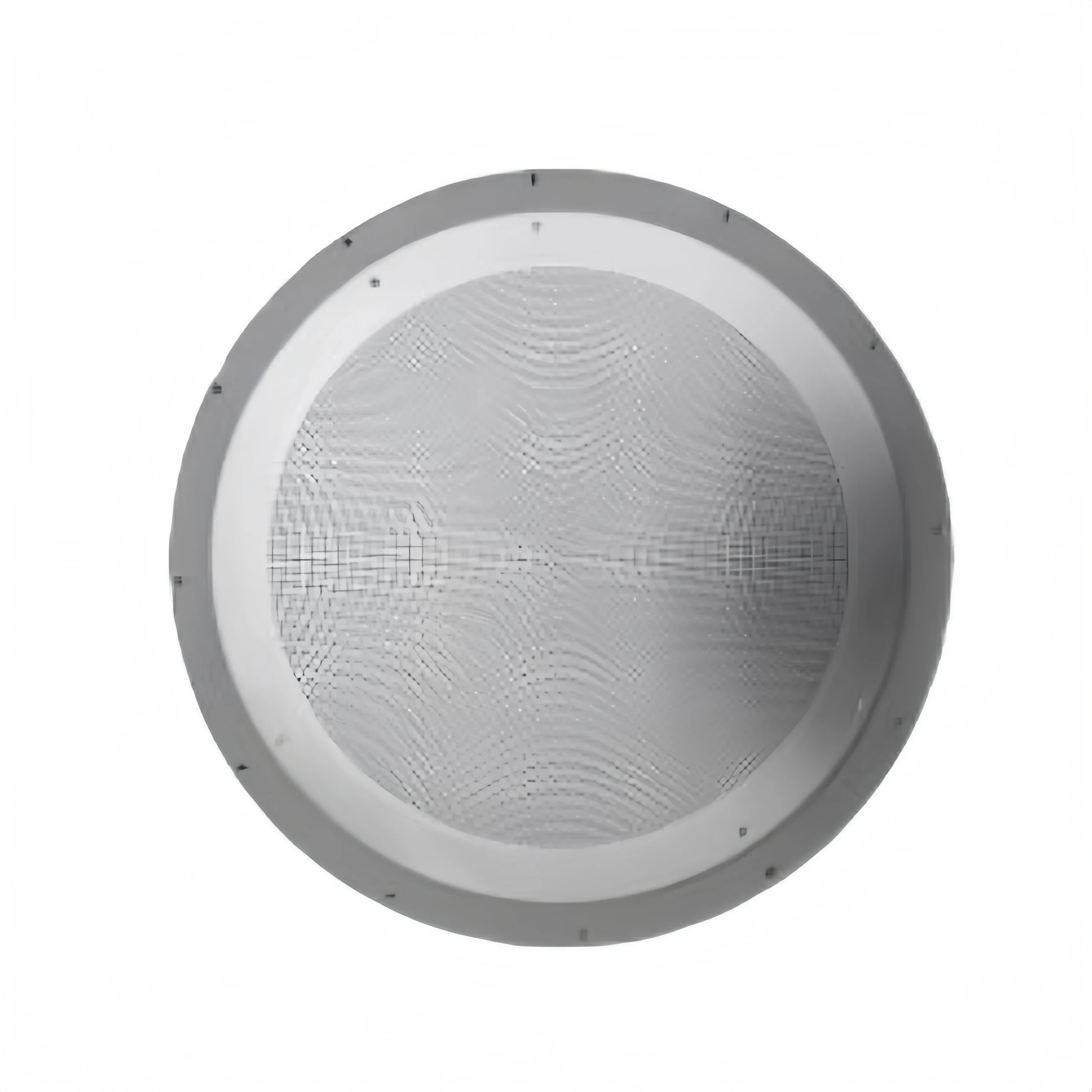

A high purity alumina gas distribution plate is a dense ceramic plate made from high purity alumina (typically ≥99.5% Al₂O₃) that sits in a PVD, PECVD or ALD chamber and meters process gases into the reactor through a large number of precisely machined micro-holes.

High Purity Alumina Gas Distribution Plate Benefits

-

Optimised micro-hole layout for film thickness uniformity

The micro-hole diameter, pattern and zone density on the High Purity Alumina Gas Distribution Plate are designed to keep gas velocity and composition uniform above the substrate, supporting tight film thickness uniformity and stable coating conditions in modern PVD and PECVD tools. -

High purity alumina body for reactive plasma environments

The plate uses high purity alumina, which offers good resistance to fluorine- and chlorine-containing process gases, helping maintain dimensional stability and surface integrity over long coating campaigns. -

Dense, vacuum-tight structure for clean operation

Dense high purity alumina is essentially non-porous and vacuum-tight, with high compressive and flexural strength, which reduces gas back-diffusion and limits particle generation compared with more porous ceramics or unprotected metal plates. -

Electrical insulation compatible with RF and plasma systems

High purity alumina provides high dielectric strength and low dielectric loss at typical RF frequencies, allowing the gas distribution plate to function as an electrically insulating component in RF-driven plasma reactors or chambers with integrated electrodes. -

Upgradable with ALD barrier coatings for extended life

When additional plasma erosion resistance is required, the alumina body can be combined with ALD ceramic barrier coatings that reduce surface erosion rate and extend the service lifetime of the gas distribution plate in aggressive chemistries.

High Purity Alumina Gas Distribution Plate Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

High Purity Alumina Ceramic Gas Distribution Plate Specification

| High Purity Alumina Gas Distribution Plate | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-HP-FP01 | Customize | |

High Purity Alumina Ceramic Gas Distribution Plate Packaging

- Each High Purity Alumina Ceramic Gas Distribution Plate is placed in a dedicated foam or molded cushioning tray to prevent edge chipping during transport.

- The tray is sealed in a clean PE or antistatic bag with desiccant where needed, then loaded into a double-wall export carton or plywood case with corner protection.