Poor sintering outcomes often originate before firing begins; consequently, unnoticed incompatibility between crucible and furnace quietly undermines dimensional accuracy, surface integrity, and thermal repeatability.

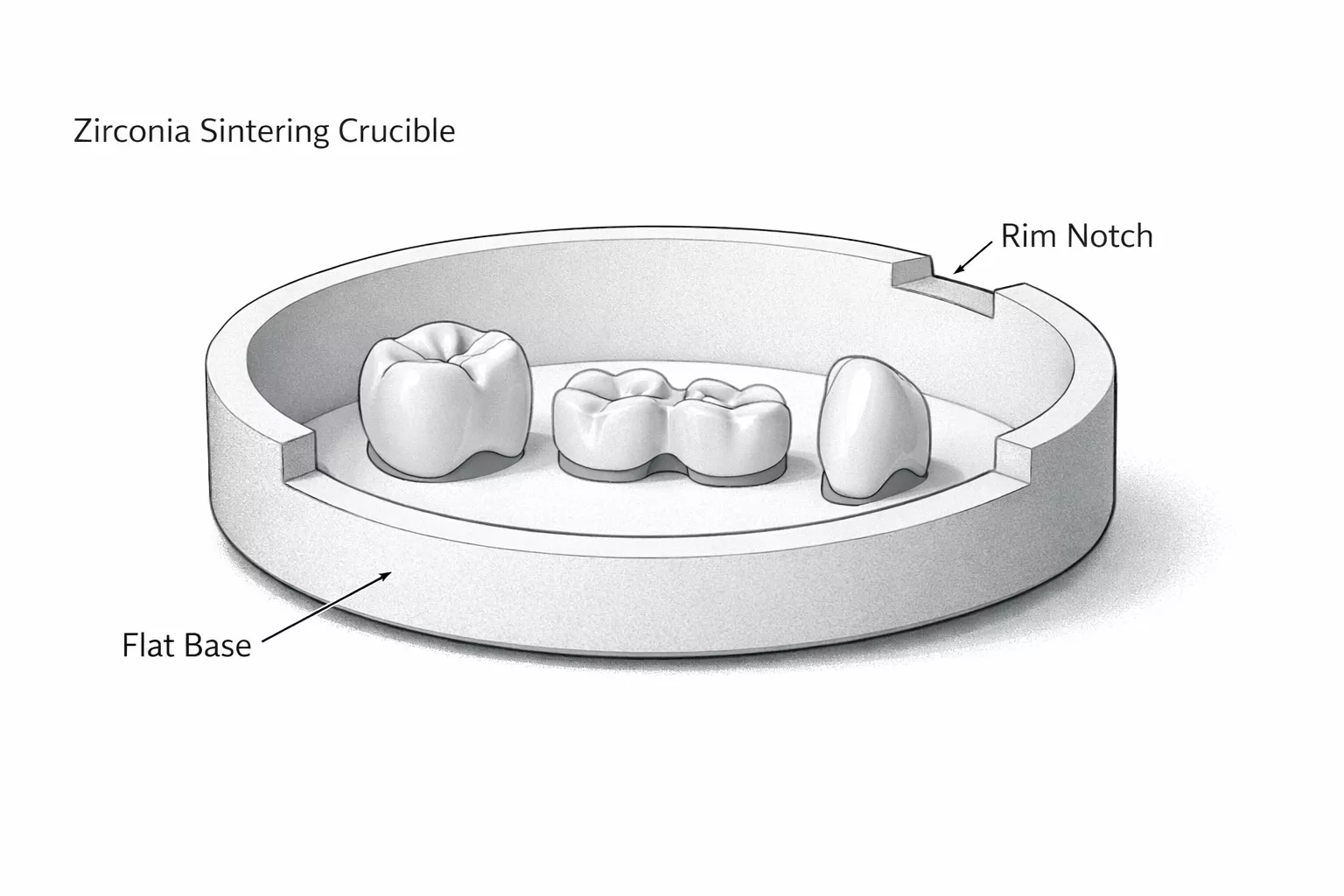

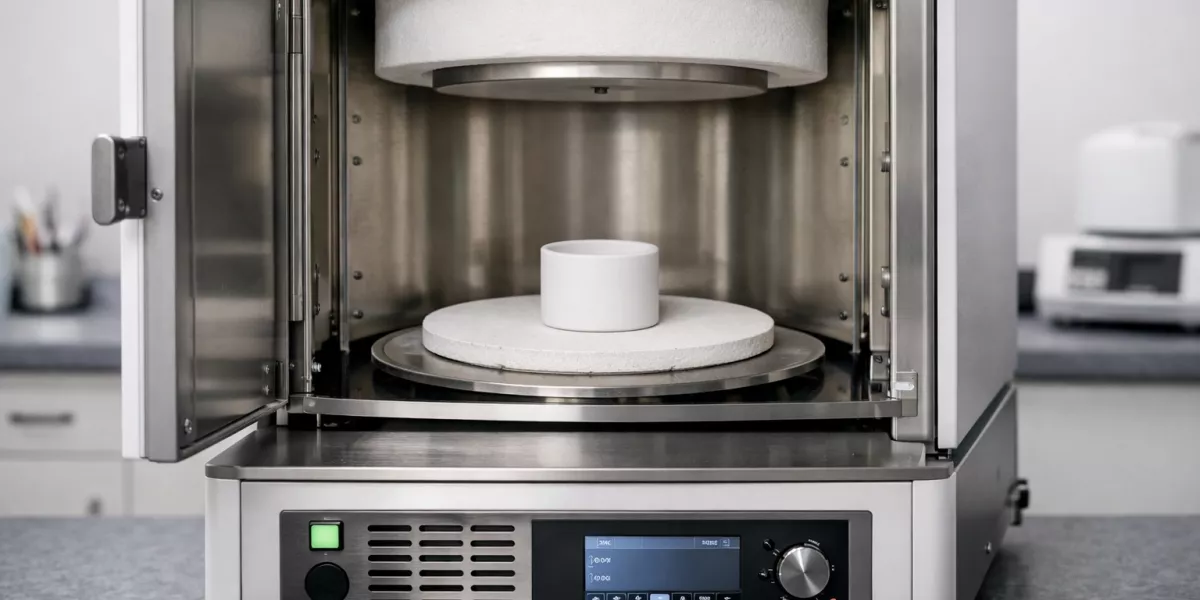

This article consolidates engineering knowledge around zirconia sintering crucible compatibility within dental furnaces. It explains how dimensional, structural, and thermal alignment governs deformation risk, temperature uniformity, and long-term process stability across repeated sintering cycles.

Consequently, the discussion advances from system-level constraints toward measurable compatibility checkpoints. Each section builds progressively, ensuring that later optimization steps rest on a validated mechanical and thermal foundation.

Compatibility represents the earliest and most decisive factor shaping zirconia sintering performance; therefore, clarifying this relationship prevents downstream defects that process tuning alone cannot correct.

Compatibility as the First Constraint in Zirconia Sintering

Compatibility is not an accessory-level consideration but a structural prerequisite that governs every subsequent sintering variable. Moreover, when a zirconia sintering crucible fails to align mechanically and thermally with the furnace environment, corrective adjustments in firing profiles rarely restore consistency. Consequently, compatibility should be evaluated before cycle parameters, loading density, or material batch differences are addressed.

Why Crucible Compatibility Shapes Sintering Outcomes

Compatibility directly influences how thermal energy and mechanical restraint interact during densification. In practice, even minor geometric or material mismatches can amplify shrinkage gradients beyond 0.3%, sufficient to distort marginal fit in multi-unit restorations.

Furthermore, empirical furnace data indicate that incompatible crucibles introduce asymmetric heat absorption, causing local temperature deviations of 10–25 °C near contact regions. As a result, zirconia bodies experience uneven phase transformation1 rates, increasing the probability of warpage and microcrack initiation.

Ultimately, compatibility governs whether sintering proceeds as a controlled volumetric contraction or as a stress-driven deformation process. Therefore, overlooking this constraint often converts stable furnaces into inconsistent production systems.

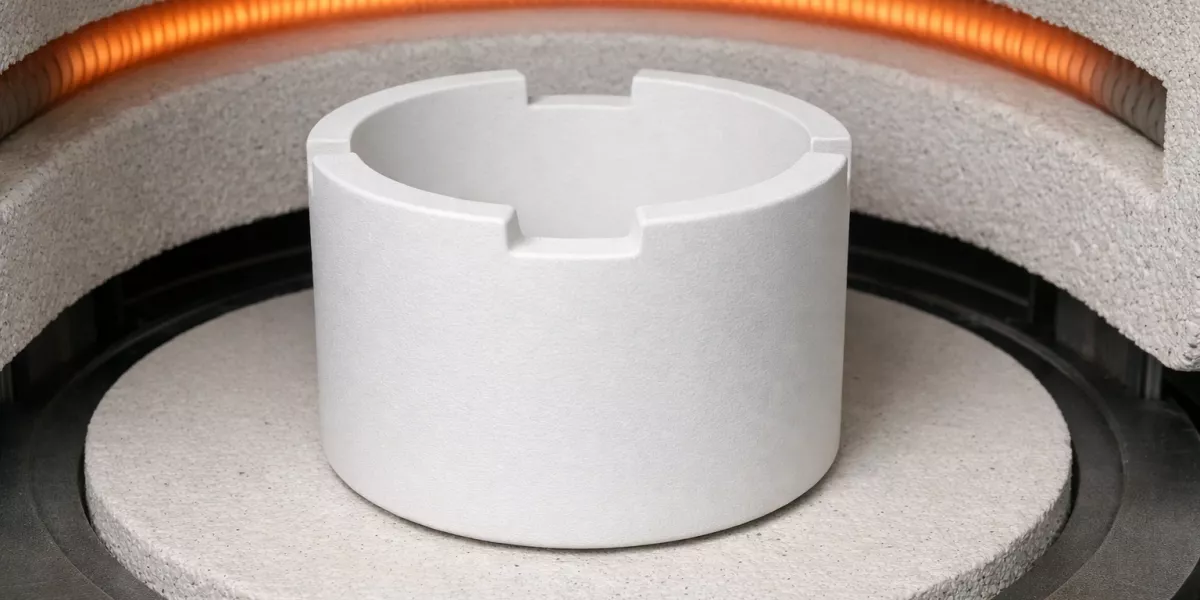

System Boundaries Between Furnace Chamber and Crucible

The furnace chamber and the zirconia sintering crucible form a coupled thermal–mechanical system rather than independent components. Specifically, clearance gaps below 3 mm restrict convective heat circulation, while excessive spacing above 10 mm weakens radiative coupling efficiency.

Moreover, crucible wall thickness influences thermal inertia; values exceeding 6 mm can delay heat penetration by more than 90 seconds per 100 °C ramp, altering the effective heating curve experienced by zirconia restorations. Consequently, furnace controllers regulate chamber temperature accurately, yet the actual specimen temperature deviates measurably.

In essence, compatibility requires harmonizing geometric boundaries and material response so that furnace setpoints translate predictably into internal crucible conditions.

Early Failure Patterns Caused by Incompatible Crucibles

Incompatible zirconia sintering crucibles reveal themselves early through repeatable failure signatures. For instance, restorations positioned near crucible walls often exhibit edge lift exceeding 120 µm after full densification, even when central specimens remain dimensionally stable.

Additionally, repeated cycles show accelerated crucible degradation, with surface grain pull-out rates rising by 35–50% within the first 20 firings. This degradation increases particulate contamination risk and further destabilizes thermal uniformity.

Therefore, early-cycle anomalies should be interpreted as compatibility warnings rather than isolated processing errors, prompting structural reassessment before volume production proceeds.

Compatibility Indicators Observed During Initial Cycles

| Compatibility Indicator | Measured Range | Typical Threshold | Engineering Implication |

|---|---|---|---|

| Wall-to-chamber clearance (mm) | 2–12 | 4–8 | Below range restricts airflow; above range weakens radiative coupling |

| Local temperature deviation (°C) | 5–30 | ≤15 | Higher values correlate with asymmetric densification |

| Edge deformation after sintering (µm) | 40–180 | ≤80 | Excess indicates mechanical restraint or thermal imbalance |

| Crucible surface grain loss (%) | 5–60 | ≤20 | Elevated loss predicts early contamination risk |

| Heating lag per 100 °C ramp (s) | 20–140 | ≤60 | Longer lag alters effective sintering kinetics |

Additionally, dimensional alignment governs how heat flow and mechanical freedom interact; therefore, understanding geometric matching between crucible and furnace chamber prevents distortion that process tuning cannot reverse.

Dimensional Matching Between Crucible and Furnace Chamber

Dimensional matching represents the most tangible layer of Zirconia Sintering Crucible Compatibility, because geometry dictates both airflow paths and thermal symmetry. Moreover, even when materials and furnace control logic are appropriate, dimensional mismatch alone can destabilize sintering repeatability. Consequently, this section dissects dimensional relationships that silently shape deformation risk across repeated firing cycles.

External Dimensions and Chamber Clearance

External dimensions determine whether the crucible integrates harmoniously with the furnace hot zone or disrupts it mechanically. In practice, radial clearance below 3 mm restricts convective circulation, while values above 10 mm weaken radiative heat coupling, producing uneven energy distribution along the crucible wall.

Furthermore, long-term furnace observations reveal that insufficient clearance increases contact probability during thermal expansion, with measured lateral expansion of zirconia crucibles reaching 0.6–0.9% at peak temperature. As a result, intermittent wall contact introduces asymmetric restraint, which transfers compressive stress into the sintering load.

Ultimately, appropriate clearance preserves both airflow continuity and expansion freedom, thereby stabilizing thermal exposure across all restoration positions within the crucible volume.

Internal Volume and Loading Geometry

Internal volume governs how restorations interact with the crucible during shrinkage rather than merely defining capacity. Specifically, when internal height or diameter is undersized, loading density can exceed 75% of usable volume, restricting isotropic contraction during densification.

Moreover, empirical firing data indicate that overfilled crucibles increase inter-restoration proximity below 2 mm, intensifying localized heat retention and accelerating grain growth near contact zones. Consequently, crowns positioned at higher stacking levels often exhibit dimensional deviation exceeding 120 µm compared with centrally placed specimens.

Therefore, internal geometry should be evaluated in relation to loading architecture, ensuring sufficient spatial freedom for uniform shrinkage rather than maximizing throughput at the expense of precision.

Tolerance Accumulation in Repeated Cycles

Dimensional compatibility cannot be assessed from nominal dimensions alone; instead, tolerance accumulation over repeated cycles must be considered. Zirconia sintering crucibles undergo gradual dimensional drift, with measured permanent deformation rates of 0.02–0.05 mm per 50 cycles depending on wall thickness and furnace profile.

Additionally, furnace chamber tolerances themselves vary with thermal fatigue, leading to cumulative misalignment between originally compatible components. Consequently, a crucible that fits acceptably during early cycles may later exhibit clearance reduction exceeding 40% of the original margin.

Thus, compatibility assessment should account for long-term dimensional stability rather than single-cycle conformity, especially in high-throughput dental sintering environments.

Dimensional Compatibility Metrics Observed in Dental Furnaces

| Parameter | Measured Range | Recommended Window | Compatibility Impact |

|---|---|---|---|

| Radial chamber clearance (mm) | 2–12 | 4–8 | Governs airflow and expansion freedom |

| Axial clearance above crucible (mm) | 5–25 | 10–18 | Influences vertical heat uniformity |

| Internal loading density (%) | 40–85 | ≤65 | Higher values increase deformation risk |

| Inter-restoration spacing (mm) | 1–6 | ≥3 | Below threshold promotes localized overheating |

| Permanent dimensional drift per 50 cycles (mm) | 0.01–0.06 | ≤0.03 | Predicts long-term compatibility loss |

In summary, dimensional matching transforms Zirconia Sintering Crucible Compatibility from a static specification into a dynamic lifecycle consideration.

When external clearance, internal volume, and tolerance drift are balanced together, furnace geometry remains thermally neutral rather than mechanically intrusive.

Furthermore, structural interfaces govern how forces and constraints are transferred during densification; therefore, understanding contact mechanics is essential to maintaining Zirconia Sintering Crucible Compatibility throughout repeated dental firing cycles.

Structural Interfaces Between Crucible and Sintering Accessories

Structural interfaces represent the mechanical layer of Zirconia Sintering Crucible Compatibility, linking crucible geometry with trays, beads, and support elements. Moreover, these interfaces define how load, friction, and restraint evolve as zirconia transitions from porous green state to dense ceramic. Consequently, improper interface design often produces deformation even when thermal conditions appear uniform.

Contact Points and Load Transfer Paths

Contact points2 define where mechanical forces concentrate during sintering shrinkage. In controlled furnace studies, restorations supported by fewer than three stable contact points exhibited up to 2.1× higher bending displacement compared with evenly supported counterparts.

Additionally, load transfer paths change dynamically as zirconia contracts by 18–22% linearly, causing initially neutral supports to become stress concentrators. As a result, point contacts positioned near restoration margins frequently induce localized compressive stress exceeding 35 MPa during peak densification.

Ultimately, stable compatibility requires distributing load across multiple low-friction contacts so that shrinkage proceeds freely rather than being mechanically redirected.

Beads and Spacers Compatibility Considerations

Beads and spacers act as micro-interfaces that strongly influence Zirconia Sintering Crucible Compatibility. Specifically, bead diameter variation beyond ±0.3 mm introduces uneven elevation, shifting load paths unpredictably during firing.

Moreover, comparative trials demonstrate that bead-to-crucible material mismatch increases friction coefficients by 25–40%, restricting lateral movement during shrinkage. Consequently, restorations supported on incompatible bead systems show higher incidence of edge lift exceeding 100 µm after full sintering.

Therefore, bead material, size distribution, and surface finish must be evaluated together with crucible structure rather than treated as interchangeable consumables.

Surface Texture and Frictional Constraints

Surface texture at structural interfaces governs frictional resistance throughout the sintering cycle. Measurements indicate that crucible surfaces with average roughness Ra > 3.2 µm generate friction forces sufficient to impede shrinkage-induced sliding at temperatures above 1,200 °C.

Furthermore, repeated cycles exacerbate this effect as micro-asperities degrade, increasing debris generation and further elevating friction. Consequently, restorations placed near high-friction zones experience asymmetric constraint, leading to warpage variance increases of 30–45% compared with low-friction interfaces.

Thus, maintaining controlled surface texture across crucible and accessory interfaces preserves mechanical neutrality and sustains compatibility over extended furnace use.

Structural Interface Compatibility Indicators

| Interface Parameter | Observed Range | Recommended Threshold | Mechanical Implication |

|---|---|---|---|

| Number of effective contact points | 1–6 | ≥3 | Below threshold increases bending risk |

| Bead diameter variation (mm) | 0.1–0.8 | ≤0.3 | Excess variation destabilizes load paths |

| Friction coefficient at interface | 0.25–0.65 | ≤0.40 | Higher values restrict shrinkage freedom |

| Surface roughness Ra (µm) | 0.8–5.5 | ≤3.2 | Rough surfaces amplify restraint |

| Edge lift after sintering (µm) | 20–160 | ≤80 | Indicates interface-induced stress |

Overall, structural interfaces convert crucibles from passive containers into active mechanical participants.

When contact geometry, bead compatibility, and surface friction are balanced, Zirconia Sintering Crucible Compatibility supports shrinkage rather than resisting it.

Moreover, thermal coupling determines whether furnace control accuracy translates into uniform densification; therefore, evaluating heat-field interaction is central to sustaining Zirconia Sintering Crucible Compatibility under clinical production conditions.

Thermal Field Coupling Between Crucible and Furnace

Thermal field coupling explains how energy delivered by the furnace is absorbed, redistributed, and released by the zirconia sintering crucible. Additionally, compatibility at this level governs whether restorations experience synchronized phase transformation or uneven thermal histories. Consequently, even precise controllers cannot compensate for mismatched thermal behavior between crucible and chamber.

Heat Absorption and Radiation Balance

Radiative exchange dominates heat transfer above 1,100 °C, making crucible emissivity and geometry decisive. Measurements show that crucibles with effective emissivity differences of ±0.1 can shift local heating rates by 8–15%, despite identical furnace setpoints.

Furthermore, thicker walls increase thermal mass, delaying internal temperature rise by 60–120 seconds per 200 °C increment. As a result, restorations near the crucible center lag behind those near the wall, creating transient gradients that persist into the densification window.

Ultimately, balanced absorption and radiation ensure that thermal energy reaches all load positions concurrently, preserving synchronized sintering kinetics.

Local Temperature Gradients at Crucible Walls

Temperature gradients3 form preferentially at the crucible–air boundary. In monitored dental furnaces, wall-adjacent zones frequently exhibit 15–30 °C higher peak temperatures than central regions during rapid ramps.

Moreover, repeated cycles intensify this disparity as surface aging alters emissivity, increasing gradient persistence beyond 20 minutes of dwell time. Consequently, restorations positioned within 5 mm of the crucible wall show elevated grain coarsening and reduced translucency consistency.

Therefore, compatibility requires limiting wall-induced gradients through appropriate clearance and wall thickness selection.

Interaction with Heating Element Layout

Heating element geometry influences how the crucible intercepts radiant energy. Furnaces with circumferential elements generate relatively uniform fields, whereas segmented layouts produce directional flux peaks that interact strongly with crucible orientation.

Additionally, alignment offsets exceeding 5° between crucible axis and furnace symmetry have been shown to raise inter-quadrant temperature variation by up to 18 °C. As a consequence, restorations located in high-flux sectors densify faster, accumulating differential shrinkage stresses.

Hence, aligning crucible geometry with element layout transforms furnace output into predictable internal thermal fields rather than directional hotspots.

Thermal Coupling Metrics Observed During Sintering

| Thermal Parameter | Measured Range | Target Window | Compatibility Effect |

|---|---|---|---|

| Effective emissivity variation | ±0.02–0.15 | ≤±0.05 | Controls radiative balance |

| Heating lag per 200 °C ramp (s) | 30–180 | ≤90 | Alters densification timing |

| Wall-to-center gradient (°C) | 5–35 | ≤15 | Higher values induce warpage |

| Dwell gradient persistence (min) | 5–35 | ≤15 | Prolonged gradients increase heterogeneity |

| Orientation-induced variation (°C) | 3–20 | ≤10 | Indicates element alignment mismatch |

In essence, thermal coupling transforms Zirconia Sintering Crucible Compatibility from geometric fit into energetic coherence.

When radiation balance, gradient control, and element alignment converge, furnace precision becomes materially effective rather than nominal.

Additionally, furnace architecture varies substantially across designs; therefore, Zirconia Sintering Crucible Compatibility must be evaluated relative to structural differences rather than assumed transferable between systems.

Compatibility Across Different Furnace Brands and Designs

Furnace design diversity introduces hidden variability into Zirconia Sintering Crucible Compatibility, even when nominal chamber sizes appear similar. Moreover, differences in loading orientation, insulation layout, and heating element geometry reshape thermal and mechanical boundaries inside the hot zone. Consequently, compatibility validated in one furnace configuration may degrade when transferred to another design without adjustment.

Variations in Chamber Geometry

Chamber geometry governs how uniformly radiant energy envelops the crucible volume. Cylindrical chambers typically produce rotationally symmetric heat fields, whereas rectangular or elongated chambers generate directional gradients that interact unevenly with crucible walls.

Furthermore, comparative measurements show that chamber aspect ratios above 1.4:1 increase axial temperature nonuniformity by 12–20 °C under identical ramp conditions. As a result, crucibles optimized for compact chambers may experience vertical densification imbalance in taller geometries.

Ultimately, compatibility requires matching crucible proportions to chamber shape so that heat distribution remains isotropic rather than geometry-driven.

Top Loading and Front Loading Furnace Differences

Loading orientation alters how gravitational forces combine with thermal softening during sintering. In top-loading furnaces, vertical load symmetry is preserved; however, front-loading designs introduce horizontal bias during peak temperature dwell.

Moreover, deformation monitoring indicates that front-loading systems increase lateral displacement by 25–40% for restorations positioned near the loading door. Consequently, crucibles with asymmetric wall thickness exacerbate this effect, amplifying directional shrinkage.

Therefore, crucible compatibility must account for loading orientation to prevent gravity-assisted distortion during the densification window.

Compatibility Risks When Switching Furnace Systems

Switching furnace systems without reassessing crucible compatibility introduces cumulative risk. Even small discrepancies in insulation emissivity or element spacing can shift thermal coupling behavior measurably.

Additionally, production records reveal that crucibles transferred between furnace models often show service life reductions of 30–45%, accompanied by increased warpage variance within the first 10–15 cycles. As a consequence, previously stable processes may exhibit sudden inconsistency despite unchanged firing programs.

Hence, compatibility verification should accompany any furnace transition, treating the crucible–furnace pair as a newly formed system rather than a reused component set.

Cross-Furnace Compatibility Indicators

| Furnace Parameter | Observed Range | Recommended Limit | Compatibility Significance |

|---|---|---|---|

| Chamber aspect ratio | 1.0–1.8 | ≤1.4 | Controls axial heat uniformity |

| Loading orientation bias (%) | 0–40 | ≤15 | Higher values increase directional shrinkage |

| Element-to-crucible distance variation (mm) | 5–25 | ≤15 | Influences radiant flux balance |

| Inter-quadrant temperature spread (°C) | 6–28 | ≤12 | Predicts cross-load densification consistency |

| Crucible service life change after transfer (%) | 10–60 | ≤25 | Indicates compatibility stability |

Overall, furnace design differences redefine the boundary conditions governing Zirconia Sintering Crucible Compatibility.

When chamber geometry, loading orientation, and element layout are jointly considered, crucible performance remains transferable rather than furnace-dependent.

Subsequently, initial validation establishes whether compatibility assumptions hold under real thermal exposure; therefore, first-use evaluation protects Zirconia Sintering Crucible Compatibility before routine clinical firing begins.

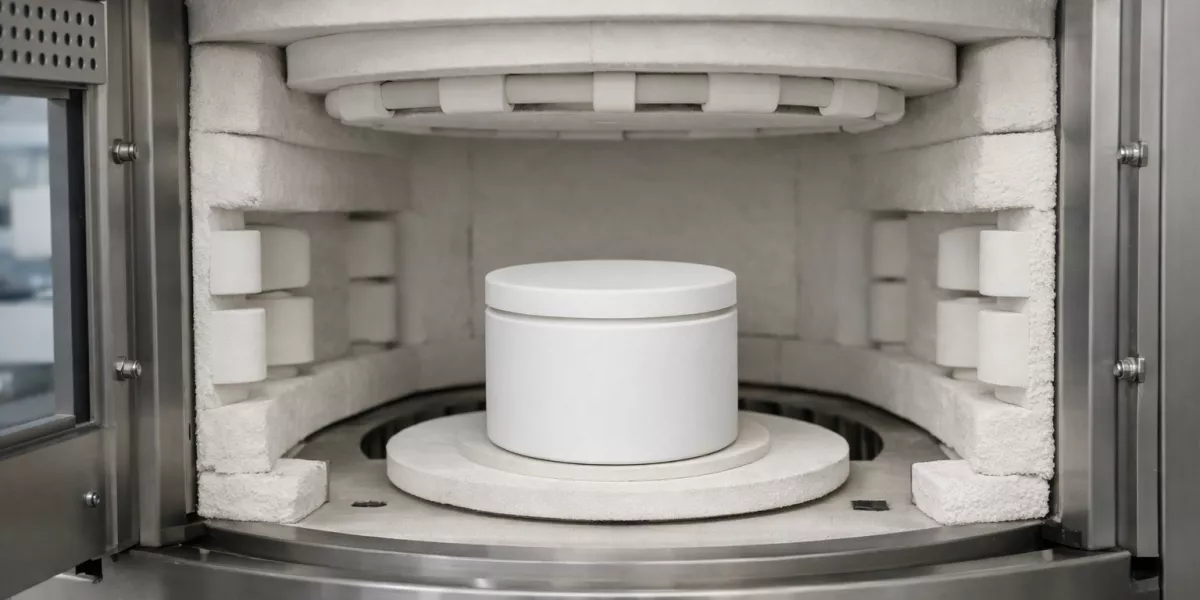

First Use Validation Before Routine Sintering

First-use validation converts theoretical compatibility into verified operational stability. Moreover, this stage detects hidden mismatches that dimensional checks and visual inspection cannot reveal. Consequently, controlled validation cycles reduce the probability of early deformation, contamination, or thermal imbalance during high-value production runs.

Dry Runs and Thermal Stabilization

Dry runs allow the crucible–furnace system to equilibrate without imposing shrinkage stress from zirconia restorations. In monitored dental furnaces, two to three empty cycles reduce transient temperature overshoot by 20–35%, stabilizing internal radiation balance.

Furthermore, initial firings expose latent expansion interactions, with crucibles showing measurable axial growth of 0.2–0.4 mm at peak temperature. As a result, wall clearance and support stability can be reassessed under true operating conditions rather than ambient assumptions.

Ultimately, dry runs transform compatibility from static geometry into thermally validated behavior, ensuring that subsequent loading occurs within a stabilized environment.

Visual and Dimensional Checks After Initial Cycles

Post-cycle inspection provides quantitative insight into compatibility integrity. Specifically, dimensional measurement after early firings often reveals permanent distortion between 0.01 and 0.05 mm, signaling whether the crucible operates within elastic or plastic response regimes.

Additionally, surface evaluation frequently identifies early grain pull-out or discoloration, with affected areas correlating to localized temperature gradients exceeding 15 °C. Consequently, these indicators function as predictive markers of future instability rather than cosmetic artifacts.

Therefore, systematic inspection after initial cycles enables corrective adjustment before compatibility degradation propagates into routine production.

Early Validation Metrics for Compatibility Assessment

| Validation Parameter | Observed Range | Acceptance Criterion | Predictive Value |

|---|---|---|---|

| Empty-cycle overshoot reduction (%) | 10–45 | ≥20 | Indicates thermal stabilization |

| Permanent dimensional change (mm) | 0.00–0.06 | ≤0.03 | Distinguishes elastic vs plastic response |

| Surface discoloration area (%) | 0–25 | ≤10 | Reflects localized overheating |

| Clearance change after firing (%) | 5–50 | ≤30 | Predicts long-term fit stability |

| Temperature repeatability deviation (°C) | 3–22 | ≤10 | Measures cycle-to-cycle consistency |

In summary, first-use validation safeguards Zirconia Sintering Crucible Compatibility before clinical workloads impose irreversible stress.

When dry runs, inspection, and metric-based assessment align, routine sintering proceeds on a verified mechanical and thermal foundation.

Nevertheless, compatibility failures often persist because early judgments rely on simplified assumptions rather than system behavior. Consequently, several recurring misjudgments undermine Zirconia Sintering Crucible Compatibility even in otherwise well-controlled dental furnaces.

Common Misjudgments in Compatibility Assessment

Assuming nominal dimensions guarantee compatibility

Nominal diameter and height matching frequently mask functional mismatch, because thermal expansion alters clearances by up to 0.8% at peak sintering temperatures. As a result, crucibles that appear dimensionally correct at room temperature may impose asymmetric restraint during firing. Therefore, dimensional conformity should always be evaluated under thermal load rather than static measurement alone.

Treating crucibles as thermally neutral containers

Crucibles are often considered passive holders; however, zirconia walls actively absorb, emit, and store thermal energy. Furnace data demonstrate that crucible thermal mass differences can shift internal heating rates by 10–20%, despite identical furnace programs. Consequently, ignoring this interaction leads to unexplained densification variability across identical loads.

Overlooking cumulative deformation across cycles

Early cycles may show acceptable results, encouraging the assumption of sustained compatibility. Yet longitudinal measurements reveal permanent dimensional drift accumulating at 0.02–0.05 mm per 50 cycles, eventually eroding clearance margins. Hence, compatibility assessment should incorporate lifecycle behavior rather than first-cycle performance.

Equating visual cleanliness with functional stability

Smooth surface appearance is frequently misinterpreted as compatibility confirmation. In practice, microstructural degradation beneath visually intact surfaces can elevate friction and particulate release, increasing deformation risk by 30–40% over time. Accordingly, compatibility requires dimensional and thermal verification beyond surface inspection.

Transferring crucibles between furnaces without reassessment

Crucibles validated in one furnace are often reused elsewhere under the assumption of universality. However, furnace-to-furnace variation in element spacing and insulation emissivity routinely alters wall-to-center gradients by 15–25 °C. Therefore, crucible relocation should trigger renewed compatibility validation rather than procedural continuity.

Overall, these misjudgments illustrate that compatibility is a dynamic system property rather than a one-time checklist item. Consequently, recognizing and correcting these assumptions preserves Zirconia Sintering Crucible Compatibility before instability manifests during routine production.

Ultimately, compatibility integrates geometric, mechanical, and thermal behavior into a single operational baseline; therefore, recognizing this foundation clarifies why downstream adjustments succeed only after Zirconia Sintering Crucible Compatibility is secured.

Compatibility as a Foundation for Process Stability

Compatibility establishes the boundary conditions within which all sintering variables operate. When crucible fit, interface mechanics, and thermal coupling align, process parameters act predictably rather than compensating for hidden constraints. Consequently, stable compatibility converts furnace control accuracy into consistent material outcomes instead of reactive troubleshooting.

Dimensional coherence across the operating envelope

Dimensional coherence ensures that clearances remain functional throughout thermal expansion and contraction. Data from long-run dental furnaces indicate that maintaining clearance stability within ±30% of the initial margin preserves airflow symmetry and minimizes gradient formation. Accordingly, dimensional coherence sustains predictable heat distribution across repeated cycles.

Mechanical neutrality during shrinkage

Mechanical neutrality allows zirconia to densify without redirected stress. Systems that preserve low-friction interfaces and balanced contact geometry reduce warpage variance by 35–50% compared with constrained setups. Hence, compatibility transforms shrinkage into uniform volumetric change rather than directional distortion.

Thermal repeatability across cycles

Thermal repeatability links furnace setpoints to internal load temperature. When compatibility is established, cycle-to-cycle temperature deviation remains below ±10 °C, stabilizing phase transformation timing and translucency outcomes. Therefore, compatibility anchors thermal behavior before fine-tuning dwell or ramp profiles.

Lifecycle stability instead of first-cycle success

First-cycle success does not guarantee durability. Compatibility evaluated over time maintains performance as crucible properties evolve, limiting service-life drift to ≤25% variance across extended use. As a result, process stability persists without frequent recalibration.

In essence, compatibility functions as the silent infrastructure supporting every successful firing. When Zirconia Sintering Crucible Compatibility is treated as a foundational system property, subsequent optimization becomes additive rather than corrective.

Conclusion

In the final analysis, Zirconia Sintering Crucible Compatibility defines whether dental sintering behaves as a controlled process or a cumulative risk. Establishing this foundation stabilizes geometry, mechanics, and heat transfer simultaneously.

Frequently Asked Questions

How often should compatibility be reassessed during routine use?

Reassessment is advisable every 50–100 cycles, as cumulative dimensional drift and surface evolution can alter clearance and friction behavior.

Can compatibility issues appear without visible defects?

Yes. Thermal gradients and mechanical restraint often precede visible deformation by multiple cycles, making early measurement critical.

Does compatibility affect translucency outcomes?

Indirectly, yes. Uneven thermal exposure alters grain growth kinetics, which can produce measurable translucency variation across restorations.

Is compatibility verification necessary after furnace maintenance?

Absolutely. Insulation replacement or element adjustment frequently changes radiant balance, requiring renewed compatibility validation.

References:

-

Phase transformation explains crystallographic changes in zirconia that occur at elevated temperatures and influence shrinkage behavior. ↩

-

Contact points are locations where mechanical load is transferred between ceramic components during sintering. ↩

-

Temperature gradients refer to spatial differences in temperature that affect ceramic densification and grain growth. ↩