Customization Defines Practical Reliability

Standard ceramic parts are built to satisfy broad use cases, not the realities of specific assemblies. Customization becomes necessary when real interfaces, real loads, and real environments begin to dominate performance.

Standard ceramic parts often appear suitable at first glance.

Once they are placed into real assemblies, their limitations tend to surface quickly.

Designed for averages, not actual system behavior

Ceramics cannot be corrected after installation

Small mismatches often lead to early failure

Customization Triggers in Real Projects

Most projects arrive at customization because something no longer works as expected. The need rarely comes from ambition, but from practical constraints inside existing systems.

Standard parts clash with housings, mounts, or fixtures

Cracks or wear appear once real operating conditions combine

Older systems leave little room for substitution

Small batches must balance reliability with delivery speed

Engineering-First Custom Ceramic Services

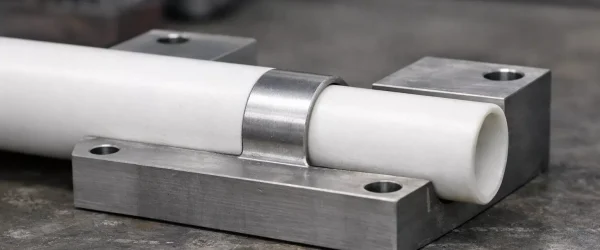

Custom Services for Ceramic Parts work best when engineering judgment leads decisions rather than drawings alone. Real operating conditions, assembly context, and failure history shape outcomes far more than geometry on paper.

Operating Condition Anchoring

Temperature, load, and media define success more than shape

Thermal mismatch and stress paths surface before production

Durability expectations guide material and structure choices

Failure-Mode-Driven Design

Geometry choices reduce chipping and thermal shock risks

Contact areas receive attention where damage actually starts

Interfaces are shaped to seal reliably, not just look precise

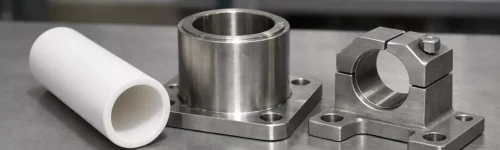

Interface-Focused Customization

Engineering effort concentrates where performance truly depends

Non-critical zones remain manufacturable and cost-controlled

Ceramics are shaped to work with metals, not fight them

Production-Ready Engineering Logic

Repeatable routes replace one-time success

Dimensional consistency improves across batches

Quality checks follow function, not formality

Customization Beyond Standard Ceramic Parts

Custom Services for Ceramic Parts go deeper than dimensions, focusing on parameters that decide real-world performance.

Material System Selection

Materials are chosen for risk, not labels

Expansion and heat flow match system demands

Media exposure guides long-term stability

Purity and Microstructure

Stability comes from what happens inside the material

Small inclusions often cause large failures

Uniform behavior matters more than peak values

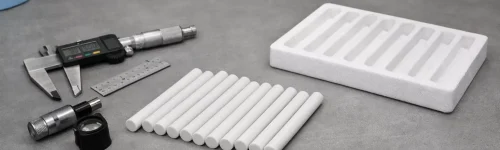

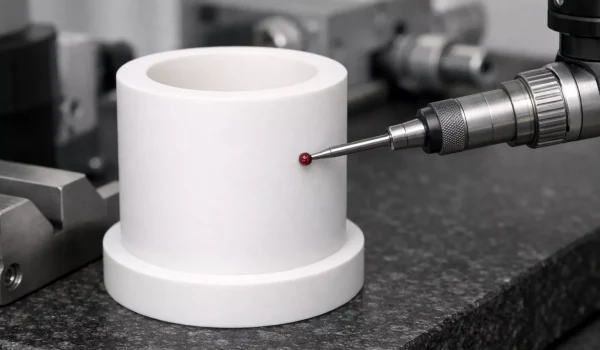

Tolerance Strategy

Tight tolerances appear only where assemblies depend on them

Ceramic forming limits are respected early

Tolerances reflect how different materials move together

Surface Engineering

Smoothness applied only where contact requires it

Avoiding unnecessary polishing shortens lead time

Finish decisions follow function, not appearance

The Right Time to Involve Engineering

Projects benefit most when engineering joins before decisions harden.

Early involvement prevents small uncertainties from becoming expensive corrections later.

Minor changes avoid major rework

Teams agree on what truly matters

Fewer surprises shorten validation

Talk With

ADCERAX Engineering Team

Many ceramic challenges become clearer through conversation rather than revision cycles.

Sharing how a part actually works inside your system often reveals workable paths forward.

Engineering teams at ADCERAX focus on turning real operating constraints into ceramic solutions that fit assemblies, timelines, and long-term performance expectations.

Share your operating conditions or drawings, and engineers can assess feasibility and customization direction.