Alumina trays—also called alumina dishes, sintering trays, and kiln furniture—provide flat, clean, high-temperature support for parts during debinding, sintering, calcination, and heat treatment. High-purity Al₂O₃ supports stable geometry at high temperature with low contamination risk.

Advantages of Alumina Trays

- Flat Loading Efficiency: Large-area trays provide stable, level support that maximizes furnace loading density and reduces wasted chamber space.

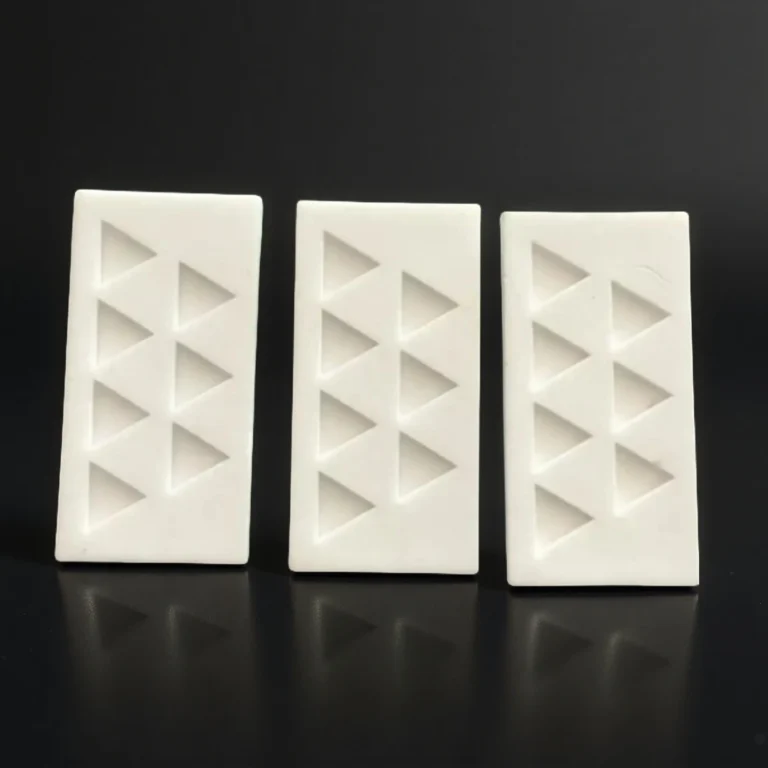

- Warp-Resistant Design Options: Customizable with V-grooves, pockets, or ribs that distribute weight evenly and minimize part sticking or surface print-through during sintering.

- Clean Process Interface: Smooth, lapped surfaces on alumina trays reduce contamination points, ensuring sensitive materials like electronic ceramics or cathode powders maintain their required purity.

Alumina Ceramic Tray Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

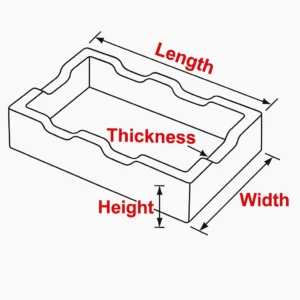

Alumina Crucible Tray Specifications

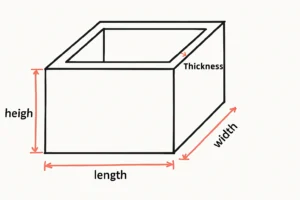

Type 1-Rectangular Alumina Trays with slotted

| Item NO. | Volume | Length (mm) | Width (mm) | Height (mm) | Thickness (mm) |

| TE-AS-205 | 64 | 100 | 100 | 13 | 5 |

| TE-AS-206 | 80 | 100 | 100 | 15 | 5 |

| TE-AS-207 | 120 | 100 | 100 | 20 | 5 |

| TE-AS-208 | 64 | 100 | 81 | 28 | 5 |

| TE-AS-209 | 22 | 100 | 100 | 15 | 6 |

| TE-AS-210 | 60 | 115 | 60 | 9 | 6 |

| TE-AS-211 | 58 | 115 | 60 | 7 | 6 |

| TE-AS-212 | 297 | 120 | 120 | 40 | 6.5 |

| TE-AS-213 | 161 | 127 | 127 | 21 | 5 |

| TE-AS-214 | 270 | 128 | 128 | 25 | 5 |

| TE-AS-215 | 355 | 135 | 135 | 35 | 9 |

| TE-AS-216 | 575 | 145 | 145 | 55 | 11 |

| TE-AS-217 | 49 | 150 | 150 | 18 | 10 |

| TE-AS-218 | 300 | 155 | 155 | 28 | 10 |

| TE-AS-219 | 350 | 200 | 105 | 30 | 10 |

| TE-AS-220 | 1634 | 220 | 180 | 80 | 14 |

| TE-AS-221 | 1400 | 230 | 230 | 45 | 12 |

| TE-AS-222 | 1752 | 230 | 300 | 50 | 12 |

| TE-AS-223 | 1080 | 230 | 165 | 60 | 12 |

| TE-AS-224 | 1467 | 248 | 155 | 62 | 13 |

| TE-AS-225 | 3000 | 250 | 250 | 100 | 10 |

| TE-AS-226 | 1137 | 295 | 195 | 55 | 10 |

| TE-AS-227 | 2565 | 315 | 158 | 83 | 13 |

| TE-AS-228 | 4100 | 320 | 320 | 60 | 10 |

| TE-AS-229 | 6000 | 320 | 320 | 75 | 10 |

| TE-AS-230 | 6500 | 320 | 320 | 85 | 10 |

| TE-AS-231 | 8900 | 320 | 320 | 110 | 10 |

| TE-AS-232 | 7500 | 320 | 320 | 110 | 14 |

| TE-AS-233 | 3900 | 320 | 320 | 60 | 14 |

| TE-AS-234 | 5000 | 320 | 320 | 75 | 15 |

| TE-AS-235 | 5000 | 320 | 320 | 80 | 15 |

| TE-AS-236 | 6000 | 320 | 320 | 85.5 | 14 |

| TE-AS-237 | 7000 | 320 | 320 | 100 | 15 |

| TE-AS-238 | 5186 | 320 | 320 | 85 | 15 |

| TE-AS-239 | 10000 | 330 | 330 | 120 | 13 |

| TE-AS-240 | 10700 | 330 | 330 | 130 | 13 |

| TE-AS-241 | 7900 | 330 | 330 | 100 | 12.5 |

| TE-AS-242 | 8000 | 330 | 330 | 100 | 13 |

| TE-AS-243 | 8200 | 330 | 330 | 100 | 12 |

| TE-AS-244 | 50 | 63 | 57 | 30 | 6 |

| TE-AS-245 | 56 | 100 | 100 | 12 | 5 |

| TE-AS-246 | 507 | 150 | 150 | 50 | 10 |

| TE-AS-247 | 100 | 160 | 160 | 15 | 8.5 |

| TE-AS-248 | 350 | 200 | 100 | 30 | 8.5 |

| TE-AS-249 | 6900 | 210 | 210 | 200 | 10 |

| TE-AS-250 | 4000 | 220 | 220 | 120 | 10 |

| TE-AS-251 | 2500 | 225 | 161 | 104 | 11 |

| TE-AS-252 | 8000 | 285 | 285 | 160 | 12.5 |

| TE-AS-253 | 7600 | 300 | 300 | 110 | 10 |

| TE-AS-254 | 11000 | 300 | 300 | 200 | 10 |

| TE-AS-255 | 7000 | 300 | 300 | 100 | 10 |

| TE-AS-256 | 6000 | 300 | 300 | 175 | 12 |

| TE-AS-257 | 5400 | 300 | 300 | 110 | 12 |

| TE-AS-258 | 8000 | 300 | 300 | 150 | 12.5 |

| TE-AS-259 | 3000 | 320 | 320 | 48 | 10 |

| TE-AS-260 | 2800 | 320 | 320 | 48 | 14 |

| TE-AS-261 | 12000 | 330 | 330 | 150 | 10 |

Type 2- Rectangular Alumina Trays

| Item | Length(mm) | Width(mm) | Height(mm) | Thickness(mm) | Purity(%) | Capacity(ml) |

| AT-AS-205 | 63 | 57 | 30 | 6 | 80-99 | 50 |

| AT-AS-206 | 100 | 100 | 12 | 5 | 80-99 | 56 |

| AT-AS-220 | 150 | 150 | 50 | 10 | 80-99 | 507 |

| AT-AS-222 | 160 | 160 | 15 | 8.5 | 80-99 | 100 |

| AT-AS-223 | 200 | 100 | 30 | 8.5 | 80-99 | 350 |

| AT-AS-225 | 210 | 210 | 200 | 10 | 80-99 | 6900 |

| AT-AS-226 | 220 | 220 | 120 | 10 | 80-99 | 4000 |

| AT-AS-228 | 225 | 161 | 104 | 11 | 80-99 | 2500 |

| AT-AS-234 | 285 | 285 | 160 | 12.5 | 80-99 | 8000 |

| AT-AS-236 | 300 | 300 | 110 | 10 | 80-99 | 7600 |

| AT-AS-237 | 300 | 300 | 200 | 10 | 80-99 | 11000 |

| AT-AS-238 | 300 | 300 | 100 | 10 | 80-99 | 7000 |

| AT-AS-239 | 300 | 300 | 175 | 12 | 80-99 | 6000 |

| AT-AS-240 | 300 | 300 | 110 | 12 | 80-99 | 5400 |

| AT-AS-241 | 300 | 300 | 150 | 12.5 | 80-99 | 8000 |

| AT-AS-243 | 320 | 320 | 48 | 10 | 80-99 | 3000 |

| AT-AS-251 | 320 | 320 | 48 | 14 | 80-99 | 2800 |

| AT-AS-259 | 330 | 330 | 150 | 10 | 80-99 | 12000 |

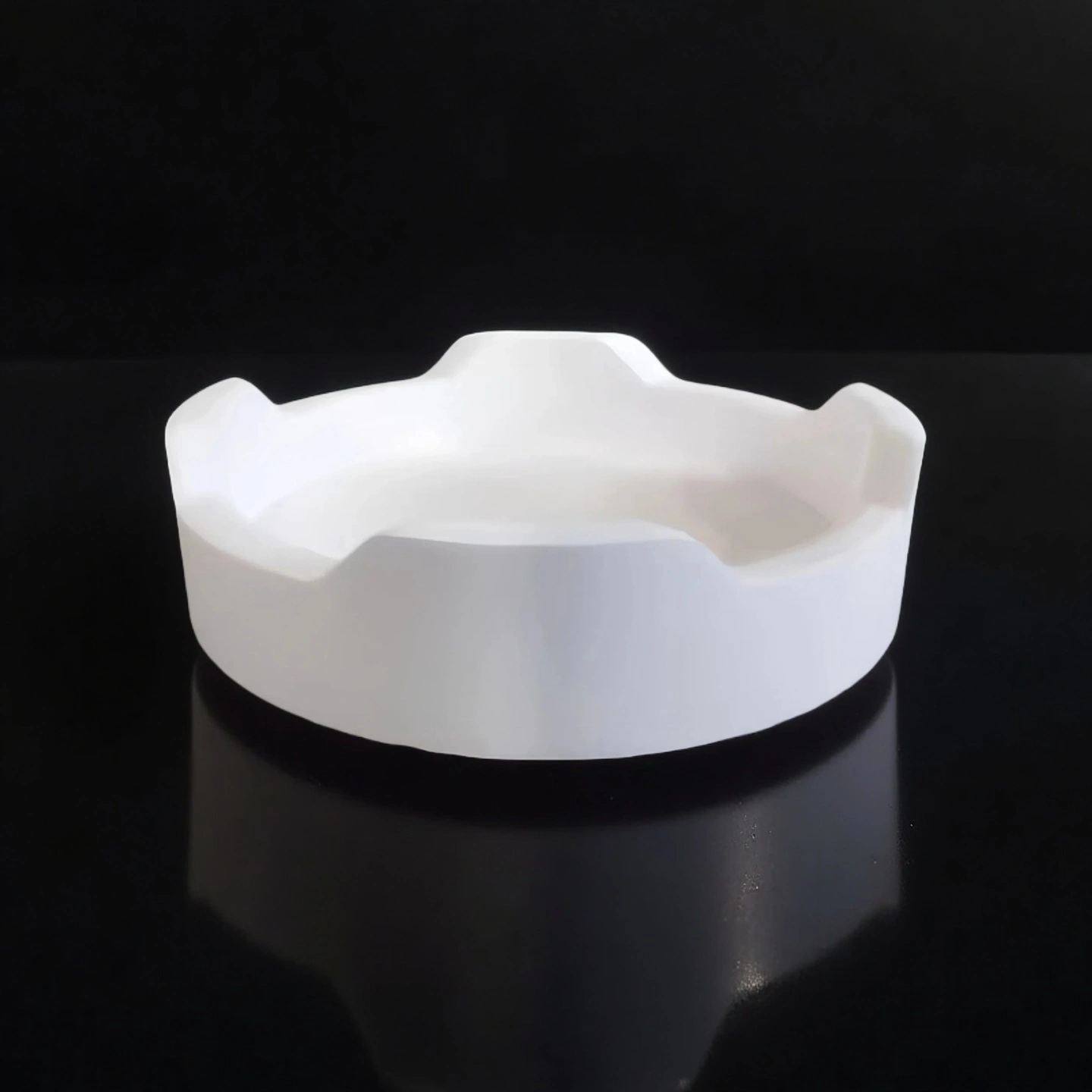

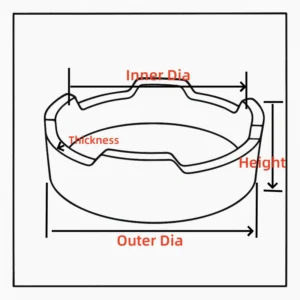

Type 3- Round Alumina Trays with slotted

| Item | Capacity(ml) | Outer Diameter(mm) | Inner Diameter(mm) | Height(mm) | Purity (%) |

| AT-AC-182 | 152 | 63 | 51 | 30 | 80-99% |

| AT-AC-183 | 51 | 70 | 60 | 24 | 80-99% |

| AT-AC-184 | 127 | 50 | 40 | 106 | 80-99% |

| AT-AC-185 | 142 | 50 | 40 | 118 | 80-99% |

| AT-AC-186 | 169 | 100 | 87 | 35 | 80-99% |

| AT-AC-187 | 210 | 78 | 57 | 89 | 80-99% |

| AT-AC-188 | 215 | 69 | 50 | 118 | 80-99% |

| AT-AC-189 | 243 | 73 | 50 | 135 | 80-99% |

| AT-AC-190 | 362 | 80 | 59 | 143 | 80-99% |

| AT-AC-191 | 373 | 70 | 50 | 200 | 80-99% |

| AT-AC-192 | 459 | 85 | 75 | 109 | 80-99% |

| AT-AC-193 | 566 | 86 | 69 | 160 | 80-99% |

| AT-AC-194 | 583 | 87 | 69 | 165 | 80-99% |

| AT-AC-195 | 610 | 107 | 82 | 128 | 80-99% |

| AT-AC-196 | 1206 | 180 | 160 | 70 | 80-99% |

| AT-AC-197 | 2155 | 200 | 170 | 110 | 80-99% |

| AT-AC-198 | 3188 | 305 | 285 | 60 | 80-99% |

| AT-AC-199 | 6330 | 260 | 240 | 150 | 80-99% |

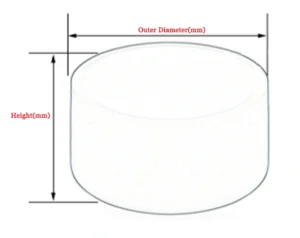

Type 4- Round Alumina Trays

| Alumina Round Trays | |||

| Item No. | Volume (ml) | Outer Diameter (mm) | Height (mm) |

| TE-AC-136 | 80 | 75 | 27 |

| TE-AC-134-1 | 80 | 75 | 27 |

| TE-AC-114 | 15 | 47 | 13 |

| TE-AC-115-1 | 15 | 47 | 13 |

*Note: The table above shows only some standard specifications. For more specifications, please refer to the complete product catalogue or contact us for customization.

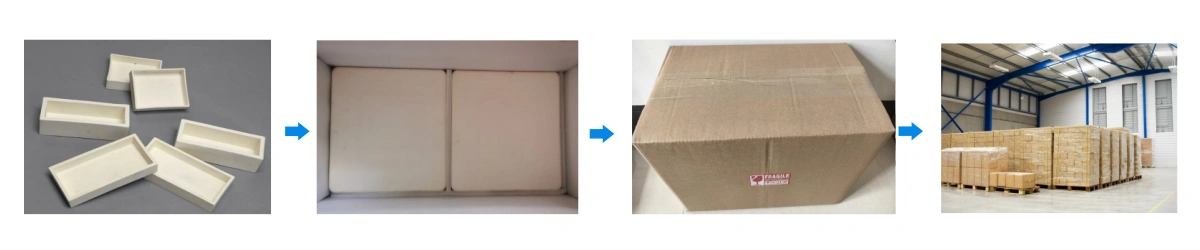

Alumina Ceramic Tray Packaging

Shock-absorbing foam with individual wrapping