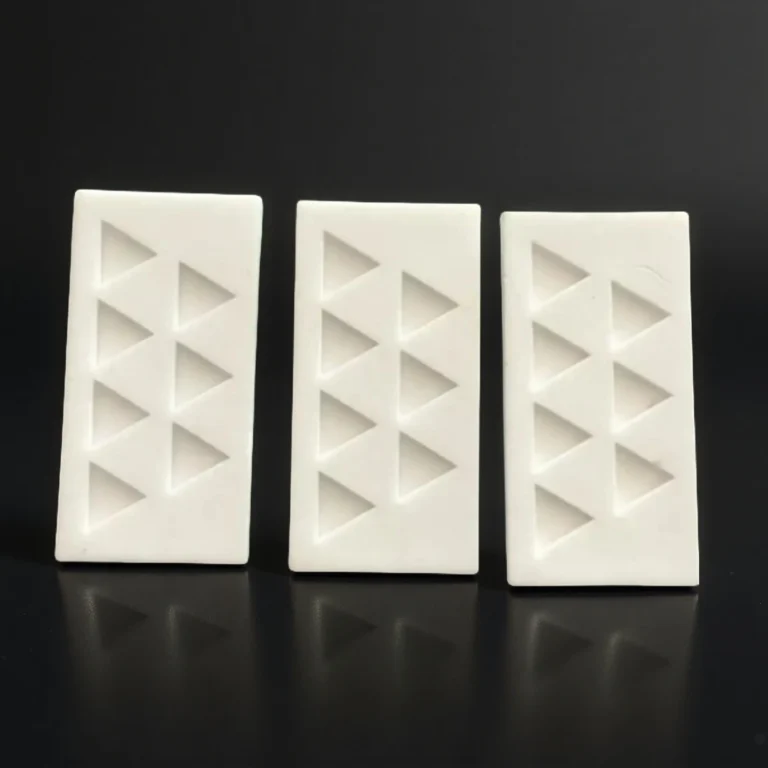

Alumina rectangular trays are rigid, corrosion-resistant ceramic carriers made from high-purity aluminum oxide (Al₂O₃). They provide a flat, clean surface for calcination, sintering, ashing, drying, and sample transfer in muffle/tube furnaces and ovens. Their geometry (rectangular dish) fits furnace shelves and allows easy loading, stacking, and handling with tongs.

Rectangular Alumina Trays Advantages

- Large flat surface area — Compared with crucibles, rectangular trays provide broad, level platforms ideal for laying out powders or multiple small parts in a single layer, which improves heating uniformity and prevents particle agglomeration.

- Stacking and loading efficiency — Their rectangular footprint fits furnace shelves more efficiently, allowing trays to be stacked or aligned side by side, maximizing furnace chamber utilization and lowering per-batch energy cost.

- Optimized for setters and fixtures — Unlike deep crucibles, rectangular trays act as setters during sintering, keeping components flat, minimizing warpage, and ensuring repeatable dimensions for powder metallurgy or advanced ceramic parts.

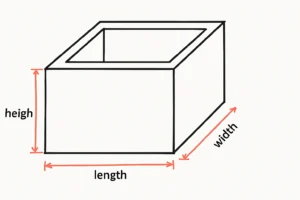

Alumina Rectangular Trays Specifications

| Alumina Rectangular Trays | ||||

| Item No. | Volume | length (mm) | width (mm) | height (mm) |

| TE-AS-061-2 | 33 | 120 | 30 | 15 |

| TE-ASJ-77 | 38 | 120 | 30 | 15 |

| TE-AS-054-3 | 39 | 113 | 30 | 18 |

| TE-AS-027-3 | 41 | 80 | 40 | 17 |

| TE-AS-038-4 | 57.4 | 100 | 30 | 25 |

| TE-ASJ-72 | 61 | 100 | 40 | 20 |

| TE-ASJ-65 | 100 | 120 | 60 | 20 |

| TE-AS-061-4 | 105 | 120 | 60 | 20 |

| TE-AS-029-6 | 111 | 95 | 65 | 22 |

| TE-AS-062-5 | 117 | 120 | 60 | 22 |

| TE-AS-062-7 | 129 | 120 | 100 | 15 |

| TE-ASJ-62 | 136 | 120 | 100 | 15 |

| TE-ASJ-49 | 207 | 100 | 100 | 25 |

| TE-AS-054-6 | 250 | 115 | 115 | 24 |

| TE-AS-069-5 | 371 | 200 | 100 | 25 |

| TE-ASJ-36 | 407 | 200 | 100 | 25 |

| TE-AS-070-30 | 1025 | 360 | 120 | 30 |

*Note: The table above shows only some standard specifications. For more specifications, please refer to the complete product catalogue or contact us for customization.

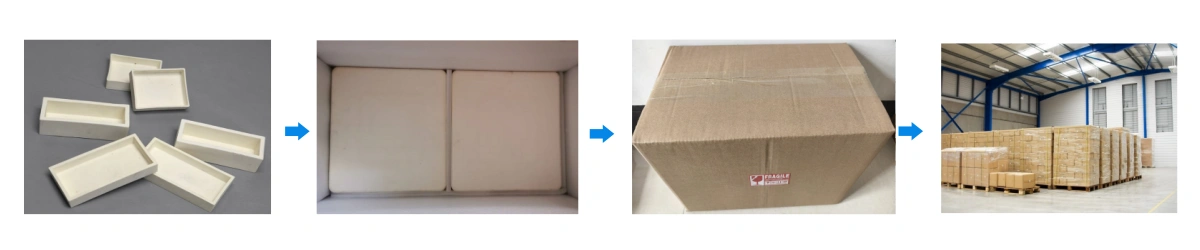

Alumina Rectangular Tray Packaging

- Individual foam protection + outer carton, with tray dividers to control chipping.

- Compatible tools: crucible tongs, setter support posts, alumina spacers;