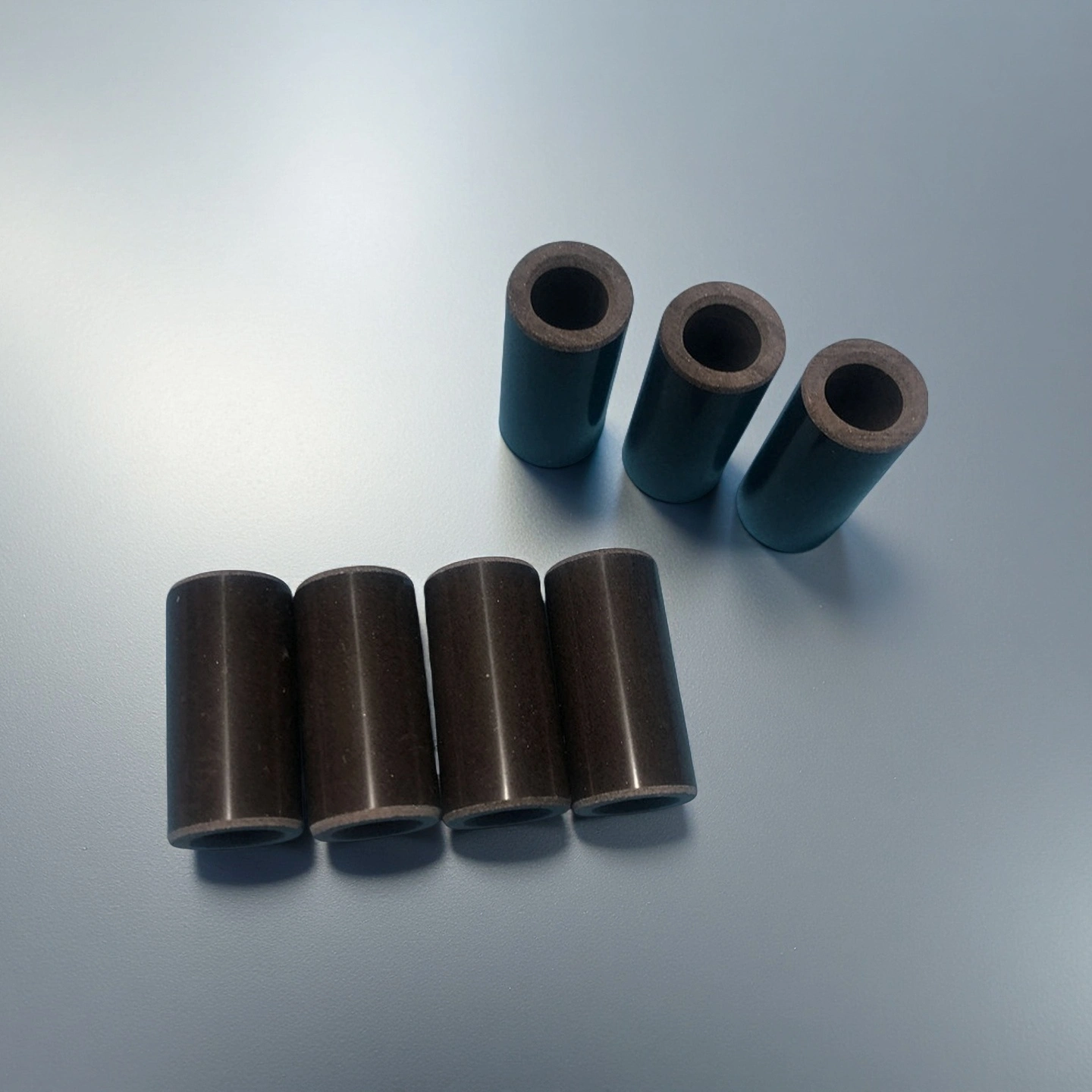

Black alumina ceramic tube is a high-temperature industrial ceramic tube made primarily from aluminum oxide (Al₂O₃) with a black ceramic body or surface treatment that adds light-absorbing properties. It combines the core advantages of alumina—high mechanical strength, electrical insulation, wear resistance, and thermal stability up to about 1600–1750 °C—with low reflectivity for optical shielding. Black alumina ceramic tubes are widely used for thermocouple protection, furnace components, sensor housings, wear-resistant liners, and optical or electronic shielding in high-temperature and corrosive environments.

Black Alumina Ceramic Tube Benefits

-

Combined high-temperature and optical performance – Black alumina ceramics retain the strength and insulation of alumina while providing strong light absorption and low reflectivity, suitable for thermal and optical environments in one component.

-

Stable strength at elevated temperature – Alumina ceramics maintain high flexural strength from room temperature to around 1100 °C and remain functional up to 1600–1750 °C in suitable atmospheres.

-

Low thermal expansion and good dimensional stability – The low thermal expansion of alumina supports dimensional stability during repeated heating and cooling cycles, reducing the risk of warping or misalignment in assemblies.

-

Electrical insulation and wear resistance in one tube – Black alumina ceramic tube provides high electrical resistivity together with abrasion resistance, allowing it to act as both insulator and wear liner in mechanical or electrical systems.

-

Resistance to many industrial chemicals – Alumina ceramics show strong resistance against many acids, alkalis, and process gases, making black alumina suitable for aggressive furnace and process atmospheres when correctly selected.

Black Alumina Ceramic Tube Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Black Alumina Ceramic Tube Specifications

| Item No. | Outer Diameter(mm) | Height(mm) | Purity(%) |

| AT-BDT-B001 | 240 | 15 | 99.5 |

| AT-BDT-B002 | 240 | 25 | 99.6 |

| AT-BDT-B003 | 245 | 25 | 99.6 |

| AT-BDT-B004 | 263 | 25 | 99.6 |

| AT-BDT-B005 | 300 | 20 | 99.6 |

| AT-BDT-B006 | 310 | 20 | 99.6 |

| AT-BDT-B007 | 350 | 15 | 99.5 |

| AT-BDT-B008 | 355 | 16 | 99.6 |

| AT-BDT-B009 | 360 | 16 | 99.6 |

| AT-BDT-B010 | 400 | 15 | 99 |

Black Alumina Tube Packaging

- Each tube is individually wrapped using foam and placed inside a rigid cardboard casing. Long isolates are cushioned with corrugated inserts.