Alumina round trays are flat, circular carriers made from dense alumina ceramic (Al₂O₃). They are designed to hold powders, pellets, samples, or components during high-temperature processes such as calcination, sintering, thermal drying, or catalyst preparation.

Alumina Round Trays Advantages

- Flatness-controlled faces keep the stacked height uniform, improving furnace loading efficiency and result repeatability.

- Dense alumina body minimizes chemical interaction and particle transfer, reducing contamination risk across cycles.

- Thickness engineered to duty (thin for fast response; thick for load-bearing) balances heat-up time and mechanical stability.

- Edge and surface options (radius, chamfer, raw/polished/sandblasted) support clean release and lower sticking.

- Atmosphere versatility (oxidation, mild reducing, vacuum) fits common lab and production recipes when specified correctly.

Alumina Ceramic Tray Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

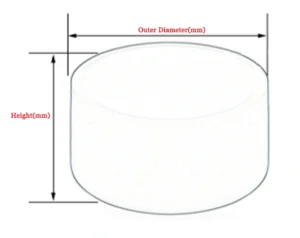

Alumina Round Trays Specifications

| Alumina Round Trays | |||

| Item No. | Volume (ml) | Outer Diameter (mm) | Height (mm) |

| TE-AC-136 | 80 | 75 | 27 |

| TE-AC-134-1 | 80 | 75 | 27 |

| TE-AC-114 | 15 | 47 | 13 |

| TE-AC-115-1 | 15 | 47 | 13 |

*Note: The table above shows only some standard specifications. For more specifications, please refer to the complete product catalogue or contact us for customization.

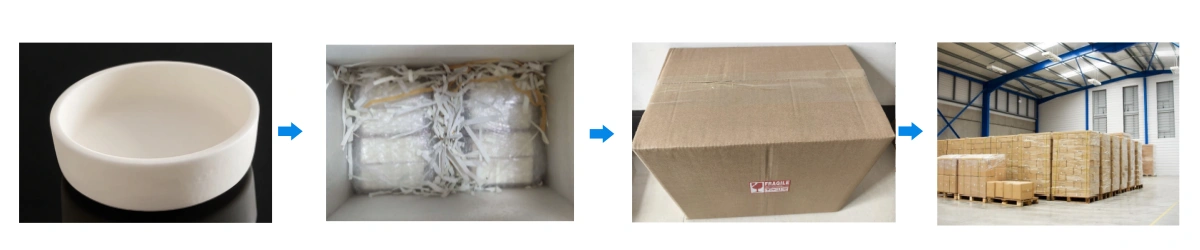

Round Alumina Trays Packaging

Protective packaging: foam-lined inner, shock-resistant outer carton; trays separated by soft interlayers.