Activated alumina balls (beads) are porous aluminum oxide desiccants engineered with high specific surface area and controlled pore structure. They remove moisture from compressed air and process gases, protect PSA/VPSA units, and adsorb contaminants such as fluoride and arsenic from water.

Activated Alumina Balls Advantages

- Stable drying performance: Maintains moisture pickup and regenerability across cycles; supports −40 °C PDP targets in standard desiccant dryers.

- Mechanical robustness: High crush strength and low dust generation minimize valve fouling and filter loading.

- Chemically clean: Neutral surface, suitable for fluoride/arsenic adsorption after proper conditioning; compatible with common compressor oils and gas constituents.

- High Adsorption Capacity: A porous structure with a surface area over 320 m²/g ensures efficient moisture and contaminant removal, achieving pressure dew points as low as -40°C.

- Mechanical Integrity: High crush strength (≥140N) and low attrition (<0.1%) prevent dusting and bed breakdown during pneumatic loading and high-pressure operation, extending service life.

Activated Alumina Bead Ball Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

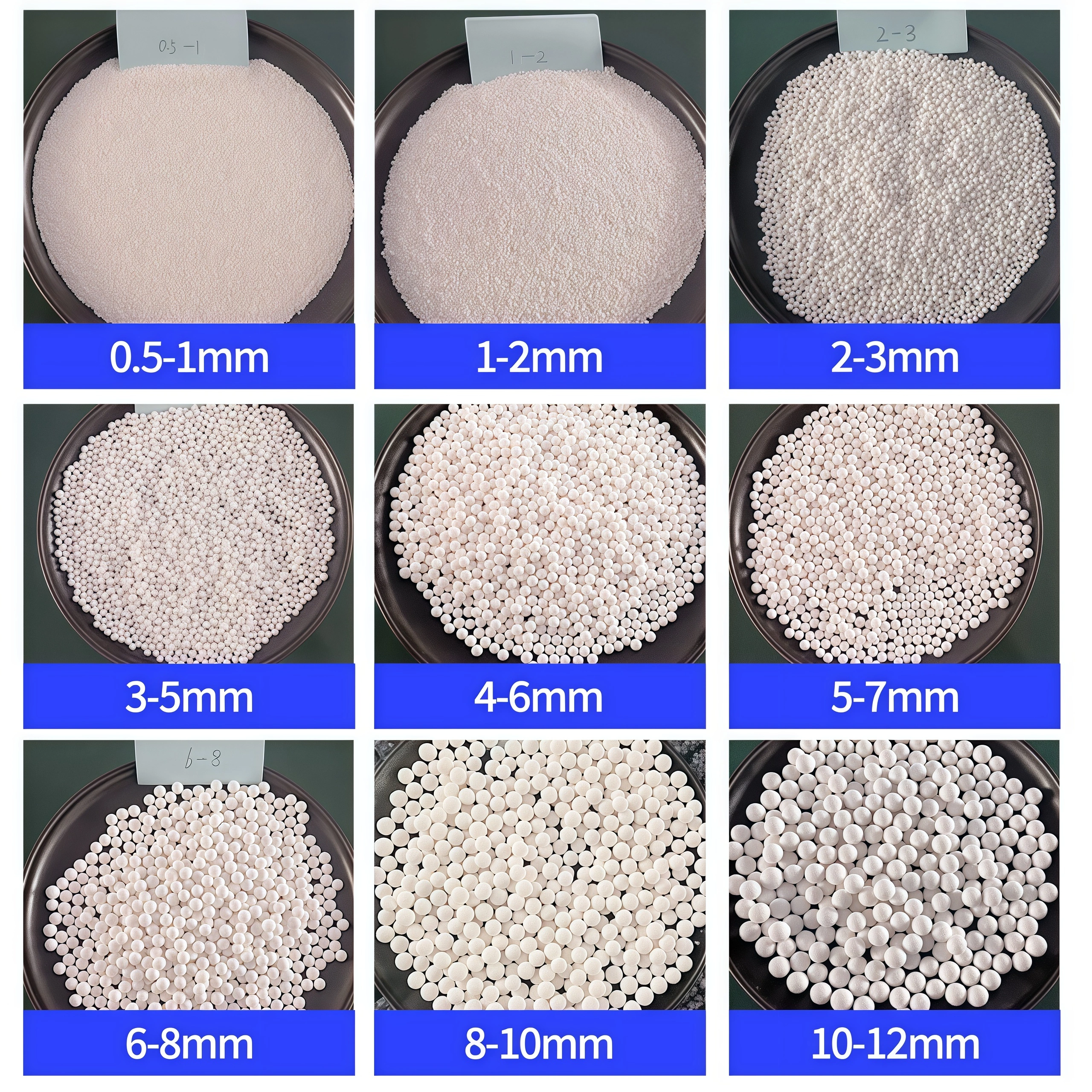

Activated Alumina Balls Specifications

| Activated Alumina Balls | |||

| Item No. | Diameter (mm) | Purity (AI203%) | Tolerance |

| AT-YM-H001 | 0.5 | 93 | ±0.2 |

| AT-YM-H002 | 1 | 93 | ±0.5 |

| AT-YM-H003 | 2 | 93 | |

| AT-YM-H004 | 3 | 93 | ±1.0 |

| AT-YM-H005 | 4 | 93 | |

| AT-YM-H006 | 5 | 93 | |

| AT-YM-H007 | 6 | 93 | |

| AT-YM-H008 | 7 | 93 | |

| AT-YM-H009 | 8 | 93 | |

| AT-YM-H010 | 9 | 93 | |

| AT-YM-H011 | 10 | 93 | ±1.5 |

| AT-YM-H012 | 11 | 93 | |

| AT-YM-H013 | 12 | 93 | |

| AT-YM-H014 | 13 | 93 | |

| AT-YM-H015 | 14 | 93 | |

Activated Alumina Oxide Ball Packaging

- High alumina balls are packaged in 25 kg heavy-duty plastic bags, which are then placed inside 1-ton jumbo bags with inner waterproof liners. The jumbo bags are palletized and shrink-wrapped for secure, moisture-free international transport.