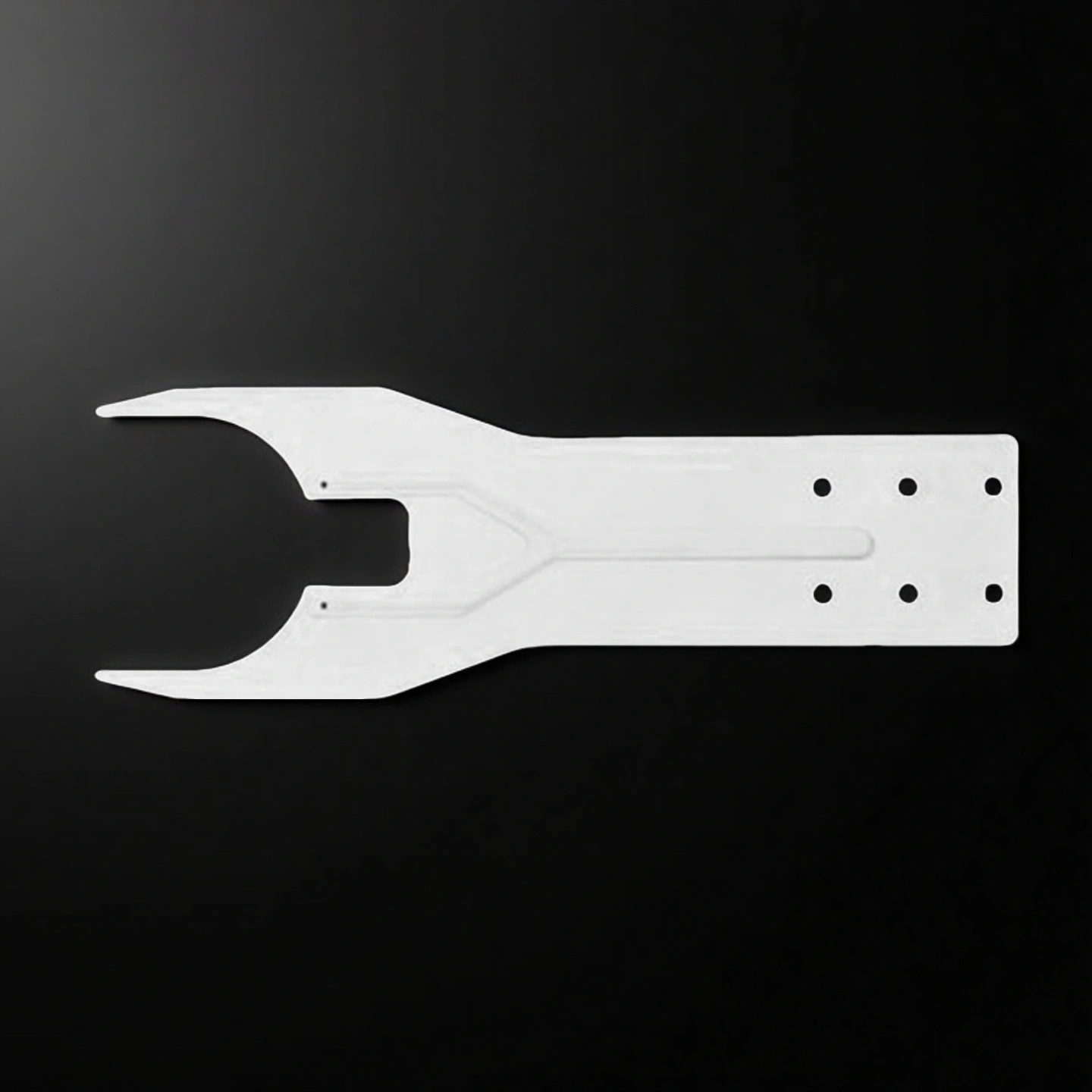

The Alumina Ceramic Robot Arm is a high-purity Al₂O₃ end-effector for clean handling, electrical insulation, and wear resistance. Available as clamping fingers, plate-type arms, or vacuum forks with internal channels, it features Ra-polished surfaces and ground planes for accurate placement with low scratch risk.

Alumina Ceramic Robot Arm Benefits

- Clean-contact surfaces — Ra-polished functional planes lower particle transfer and surface marks during handling.

- Electrical insulation — Alumina body prevents stray currents where metal claws can be risky.

- Heat-adjacent stability — Geometry remains stable near hot zones; no softening of pads or backing plates.

- Edge durability — Ground edges and optional chamfers increase resistance to chipping in repetitive cycles.

- Vacuum capability — Integrated vacuum channels can be tuned for panel size, hole pattern, and holding force.

Alumina Ceramic Robot Arm Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Ceramic Robot Arm Size

| Item No. | Diameter (mm) | Thickness (mm) | Purity |

| AT-YHL-RA001 | Customize | ||

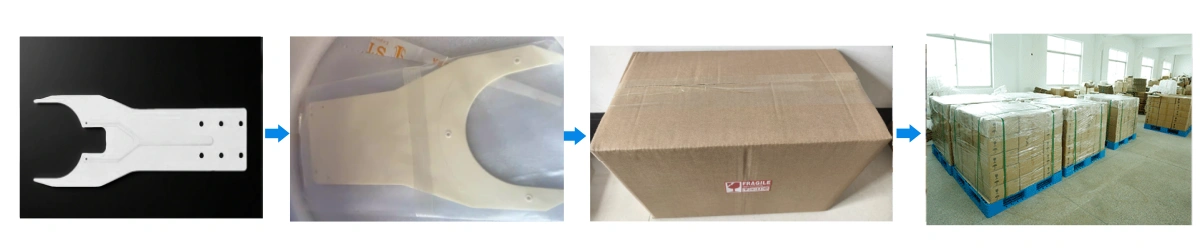

Alumina Ceramic Robot Arm Packaging

- Protection: multi-layer foam cradles, corner guards, and dust-proof bags for polished faces

- Stability: anti-vibration inserts to prevent micro-chipping in transit