Alumina ceramic insulator parts are high-purity Al₂O₃ components used to electrically isolate conductors from metal structures under high temperature and voltage. Produced as bushings, sleeves, standoffs, spacers, rings and terminal supports, they are applied in industrial furnaces, heating equipment, power electronics, high-voltage cabinets, welding systems and automation fixtures.

Alumina Ceramic Insulator Parts Benefits

-

Stable dielectric performance under high temperature

Alumina ceramic insulator parts maintain dielectric strength in the order of tens of kV/mm and high resistivity even near red-heat conditions, helping to keep insulation clearances safe in heaters, kilns and power cabinets. -

Mechanical rigidity and dimensional stability

The dense alumina body resists creep and deformation at elevated temperature, keeping bolt holes, slots and creepage distances within tolerance over long service life. -

Geometry flexibility for complex assemblies

Components can be produced as thick-wall bushings, thin spacers, long standoffs or shaped insulating blocks, allowing engineers to integrate electrical insulation and mechanical support in a single ceramic part. -

Wear and erosion resistance around live conductors

Alumina ceramic insulator parts withstand abrasion from clamping hardware, wire movement and occasional contamination better than many polymeric insulating parts in hot, dusty or chemically active environments. -

Compatibility with high-voltage and high-frequency systems

With low dielectric loss and stable permittivity, alumina insulators are suitable for power electronics, high-voltage test rigs and RF heating equipment where electrical field distribution must remain predictable.

Alumina Ceramic Insulator Parts Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Insulator Parts Specifications

Type 1: Round Alumina Plate

| Round Alumina Plate | |||

| Item no. | Diameter(mm) | Thickness(mm) | Purity |

| AT-AM1-001 | 100 | 20 | 96%-99% |

| AT-AM1-002 | 90 | 5.5 | 96%-99% |

| AT-AM1-003 | 80 | 14.5 | 96%-99% |

| AT-AM1-004 | 70 | 7.5 | 96%-99% |

| AT-AM1-005 | 60 | 4.5 | 96%-99% |

| AT-AM1-006 | 50 | 6 | 96%-99% |

| AT-AM1-007 | 40 | 5 | 96%-99% |

| AT-AM1-008 | 30 | 4 | 96%-99% |

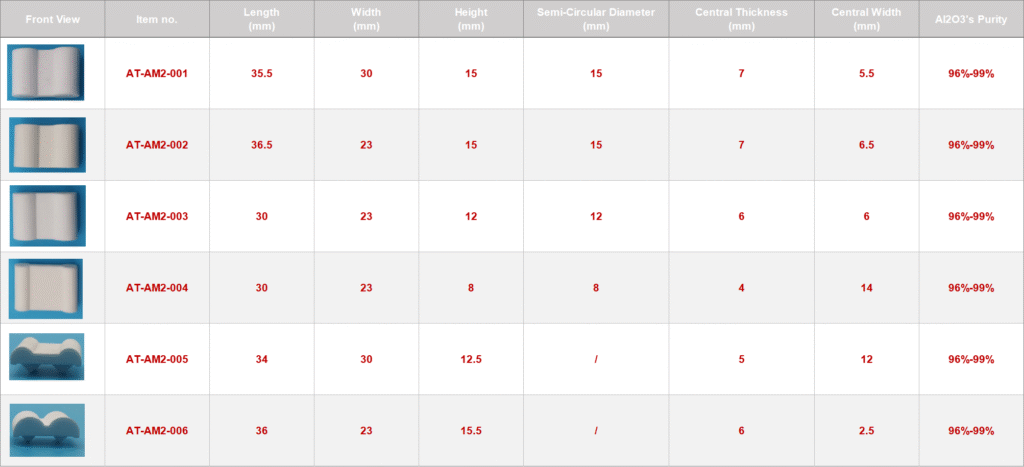

Type 2: Alumina Ceramic Cushion

Type 3: Alumina Ceramic Clip

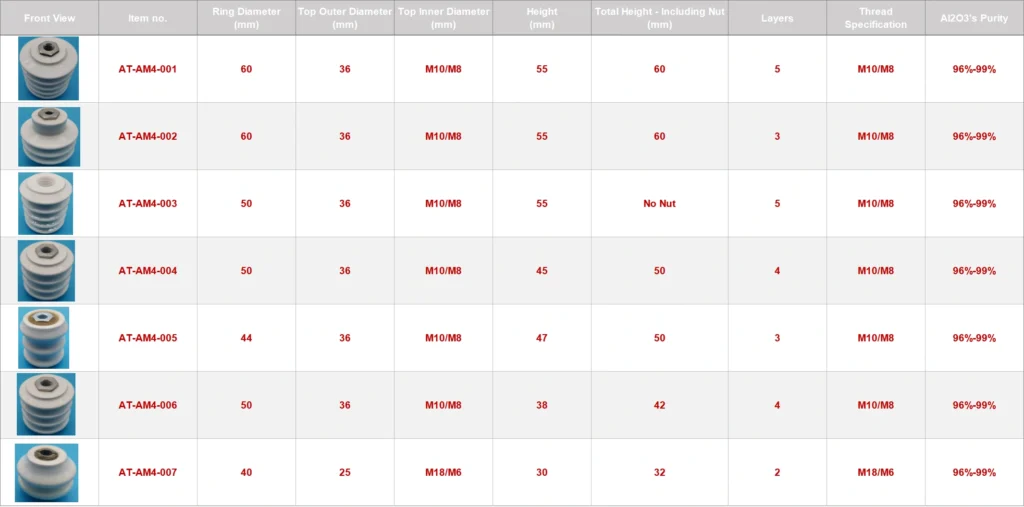

Type 4: Aluminum Oxide Heat Sink

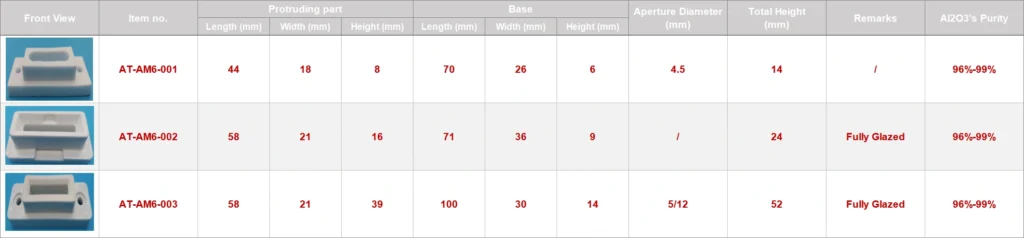

Type 5: Aluminum Oxide Connector

Type 6: Aluminum Oxide Column

Type 7: Alumina Install Ceramic Strips

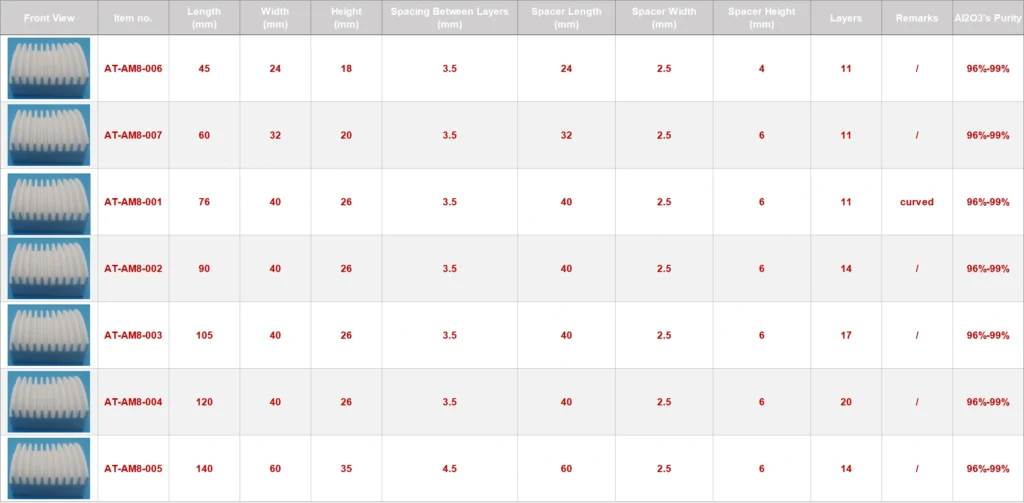

Type 8: Alumina Install Ceramic Block

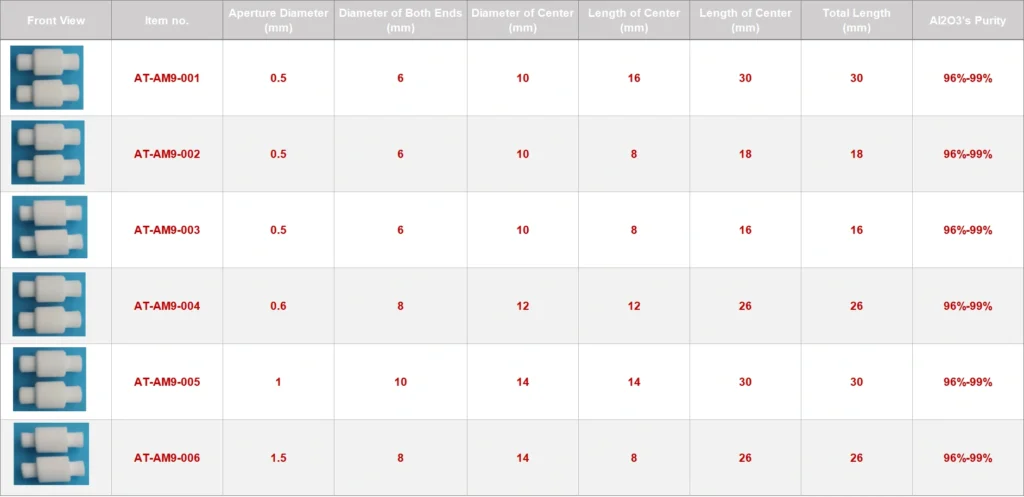

Type 9: Alumina Ceramic Sleeve I

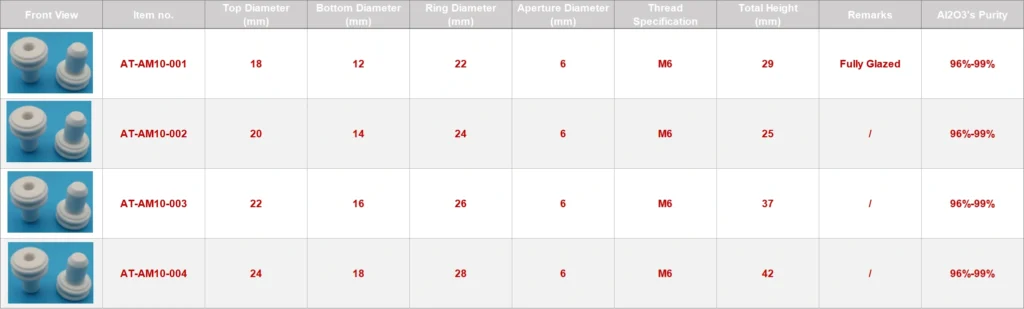

Type 10: Alumina Ceramic Sleeve II

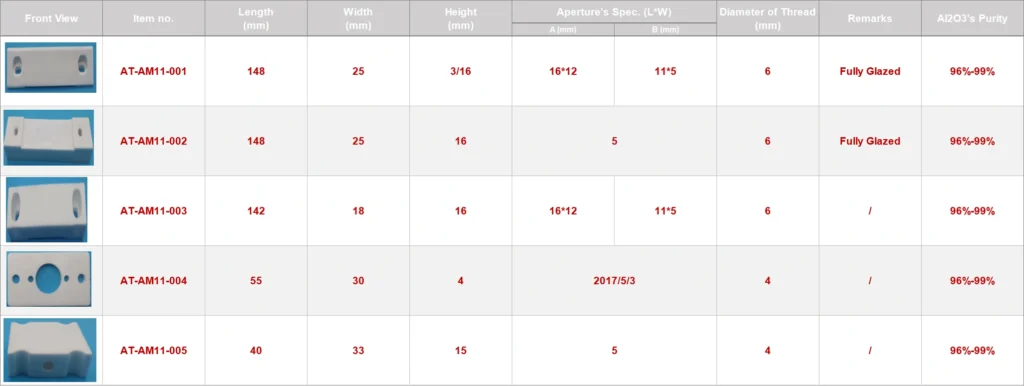

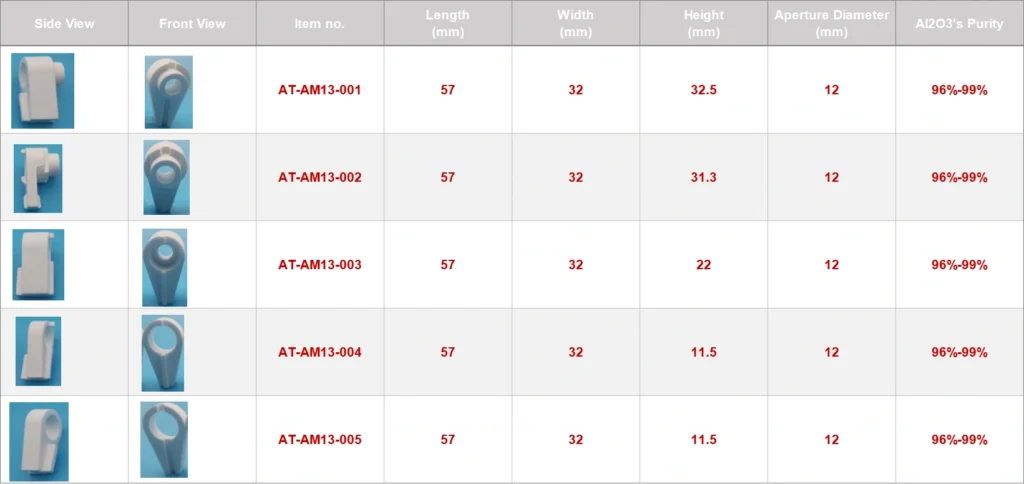

Type 11: Alumina Ceramic Seat

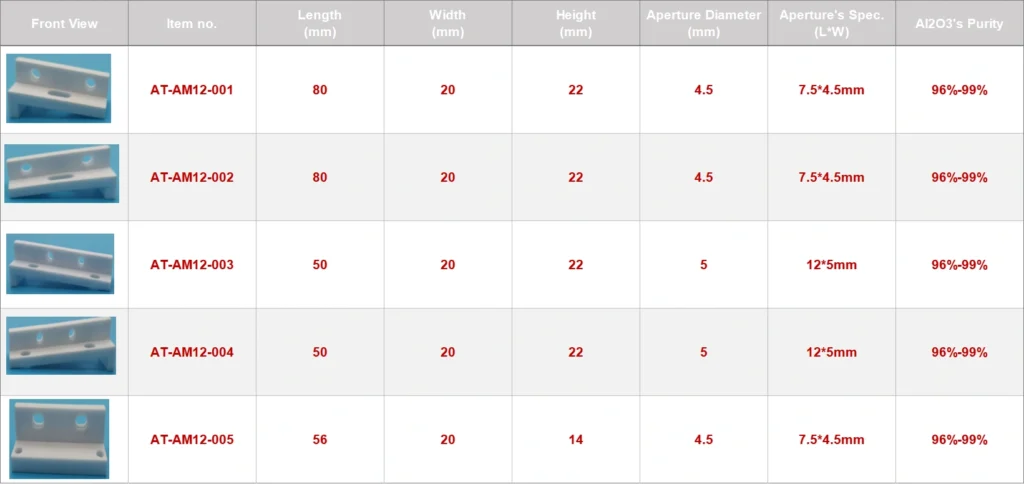

Type 12: Alumina Ceramic Terminal Support Insulator

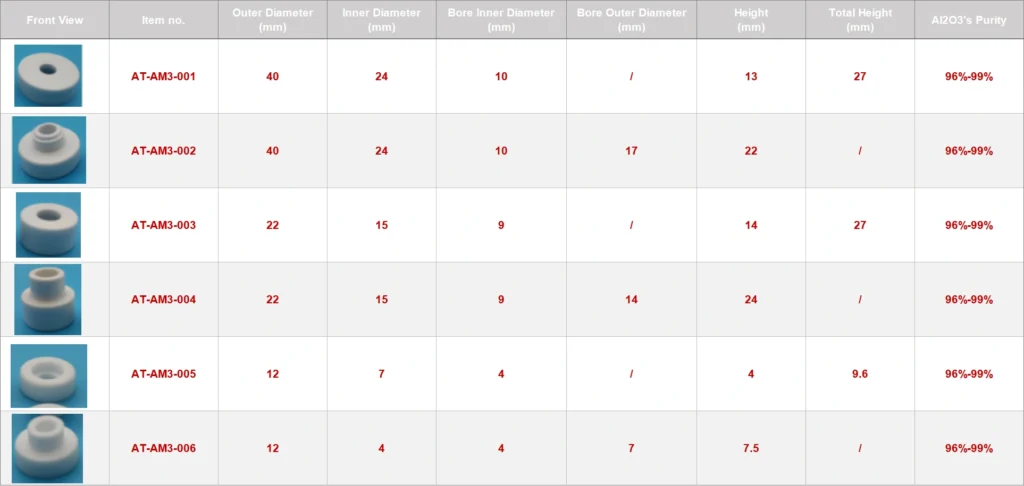

Type 12: Alumina Ceramic Support Bottle

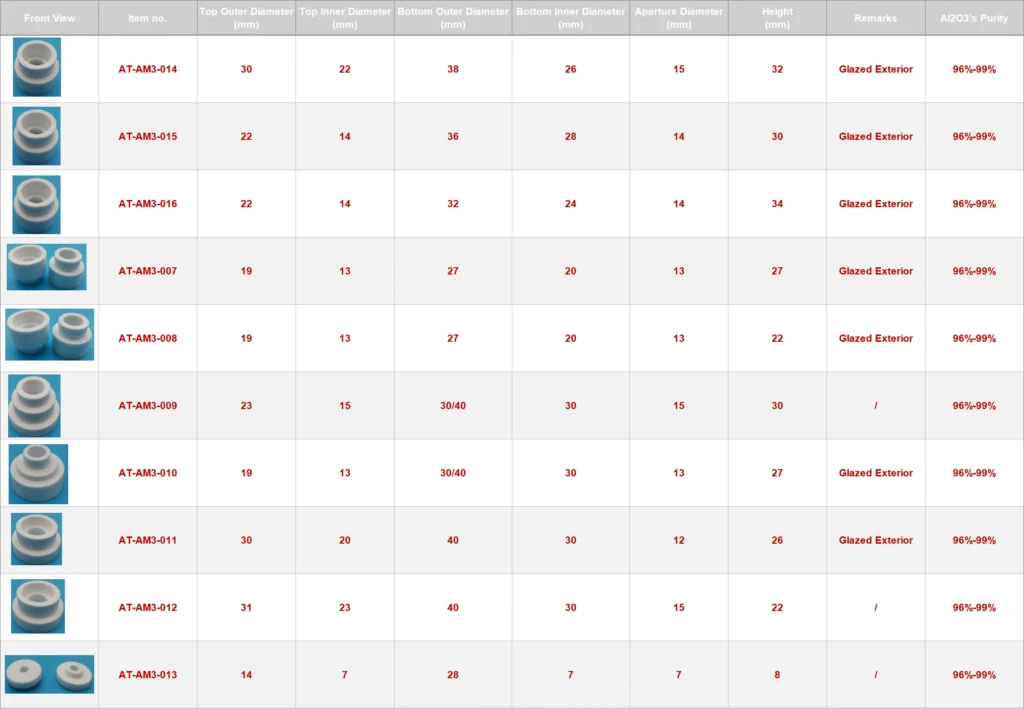

Type 12: Alumina Ceramic Wiring Seat

Alumina Ceramic Insulator Parts Packaging

- Each part or matched set is individually wrapped with soft protective material to avoid direct ceramic-to-ceramic contact and prevent edge chipping during transit.