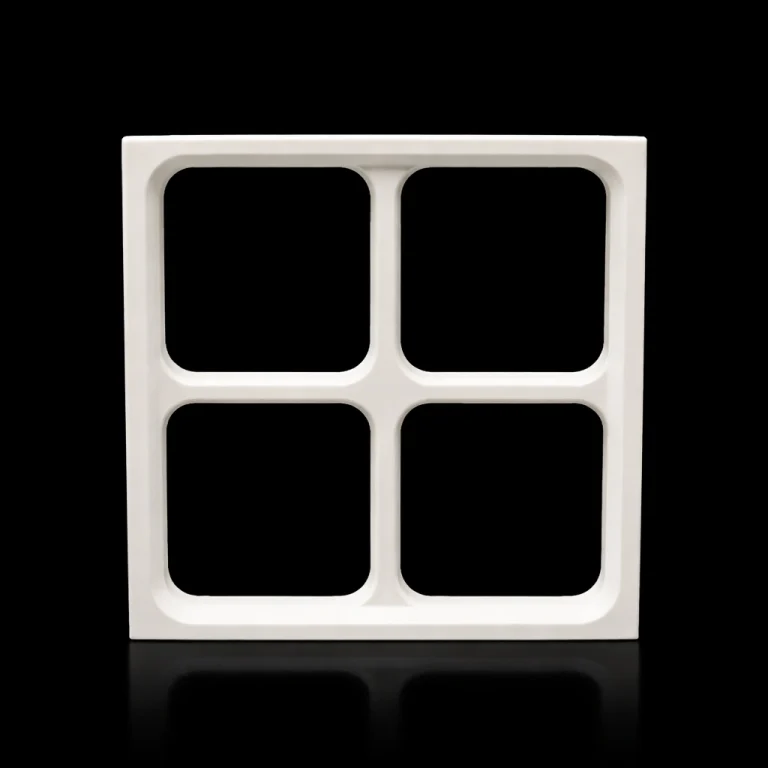

This alumina mortar and pestle set offers excellent chemical inertness, repeatable performance for sample particle reduction, and thermal resistance for high-temperature grinding processes. It serves analytical chemistry labs, material science institutes, metallurgical test centres and advanced ceramic R&D departments.

Alumina Mortar and Pestle Benefits

-

Stable grinding surface: Dense alumina mortar and pestle structure keeps roughness stable over repeated use, helping maintain similar particle size distributions between batches.

-

Low contamination design: High Al₂O₃ content and low porosity reduce material transfer from the mortar and pestle to the sample compared with porous ceramics or metallic tools.

-

Resistance to acids and alkalis: The alumina mortar and pestle can be used with many common acid and alkali cleaning solutions without rapid surface degradation, which supports frequent washing cycles.

-

Thermal stability for heated grinding: Suitable alumina grades allow the mortar and pestle to work in elevated temperature environments, such as pre-heated powders or hot drying steps in sample preparation.

-

Consistent fit between mortar and pestle: Controlled tolerances on diameter and pestle head enable even pressure distribution during grinding, which makes manual work more predictable for operators.

Al2O3 Mortar and Pestle Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Mortar and Pestle Specifications

| Alumina Mortar and Pestle | ||||||||

| Item NO. | Outer Diameter(mm) | Inner Diameter(mm) | Bottom Diameter(mm) | Height(mm) | Pestle Length(mm) | Wall Thickness(mm) | Total Weight(kg) | Capacity(ml) |

| AT-YHL-YB001 | 60 | 45 | 35 | 28 | 65 | 6.5 | 0.13 | 18 |

| AT-YHL-YB002 | 80 | 60 | 45 | 35 | 92 | 7.5 | 0.33 | 45 |

| AT-YHL-YB003 | 100 | 80 | 63 | 45 | 105 | 8.5 | 8.5 | 115 |

| AT-YHL-YB004 | 130 | 106 | 79 | 60 | 120 | 9.5 | 9.5 | 280 |

| AT-YHL-YB005 | 160 | 125 | 85 | 65 | 165 | 13 | 13 | 450 |

| AT-YHL-YB006 | 220 | 175 | 123 | 85 | 195 | 15 | 15 | 1300 |

| AT-YHL-YB007 | 255 | 210 | 135 | 100 | 225 | 17 | 17 | 1700 |

| AT-YHL-YB008 | 305 | 260 | 155 | 125 | 245 | 13 | 13 | 4000 |

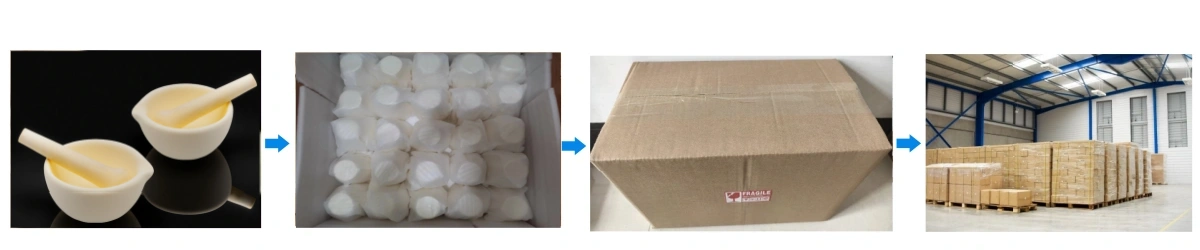

Alumina Mortar & Pestle Packaging

- Each alumina mortar and pestle set is individually wrapped with cushioning to limit contact and reduce chipping during transport.