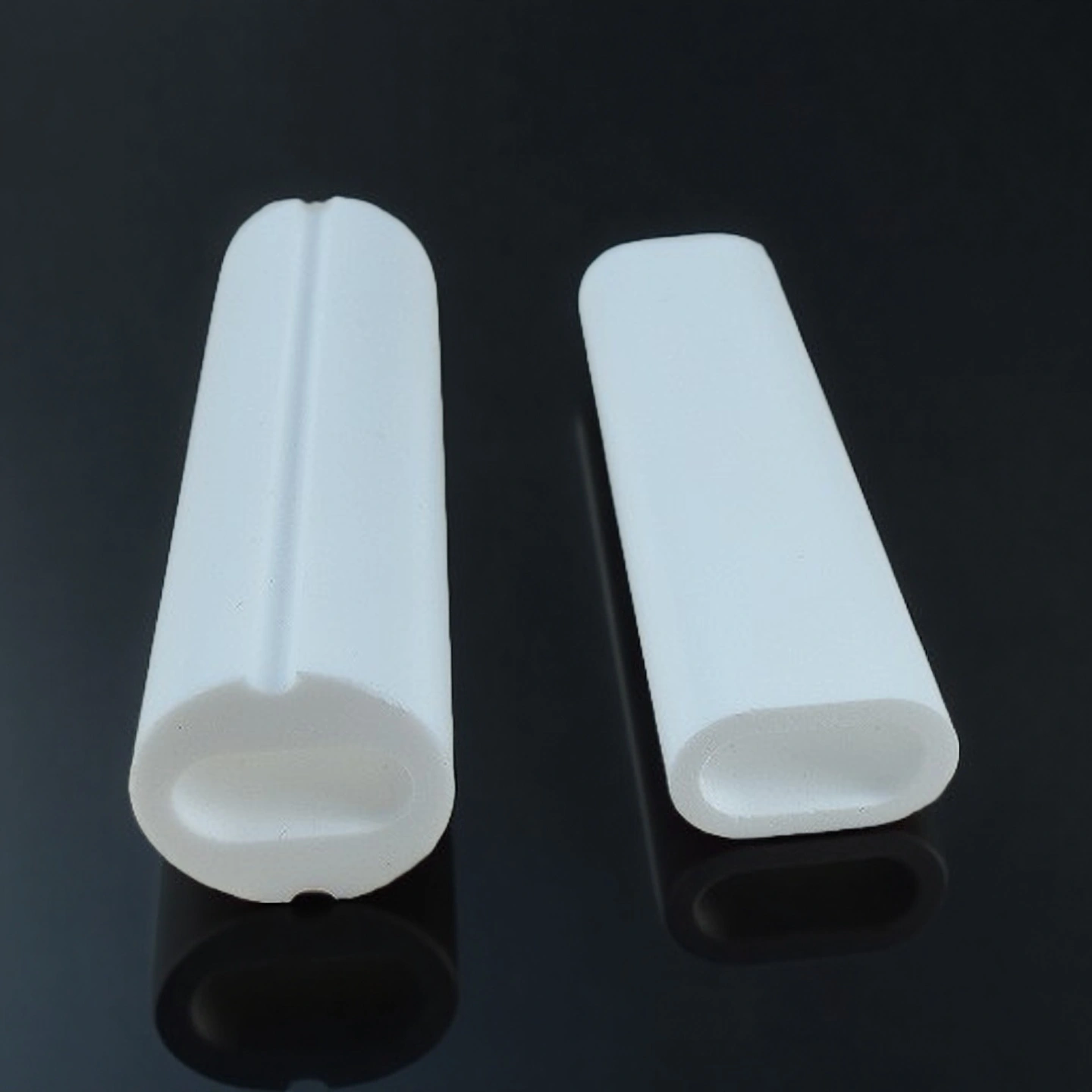

An alumina ceramic laser reflector is a diffuse, high-purity Al₂O₃ liner or insert used inside a lamp-pumped or diode-pumped solid-state (DPSS) laser pump chamber to redistribute pump light uniformly around the gain medium (e.g., Nd:YAG rod). Instead of relying on a polished metal mirror or delicate reflective coating, the alumina’s controlled micro-texture provides stable diffuse reflectance, helping suppress hot spots, improve coupling uniformity, and maintain output over long duty cycles.

Alumina Ceramic Laser Reflector Benefits

- High Alumina Density: Enhances thermal mass stability under beam exposure

- Laser Reflectivity Surface: Finished or raw ceramic surfaces, depending on application

- Custom Machining Capability: Available in plate, block, or tubular geometries

- Corrosion Resistance: Ensures durability in chemically aggressive zones within closed optics systems

Alumina Laser Cavity Liner Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Ceramic Laser Reflector Specifications

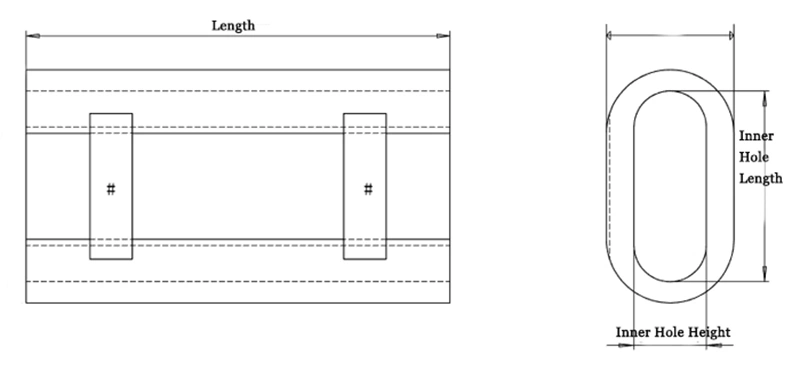

Type 1: Elliptical Alumina Laser Reflector

| Elliptical Alumina Laser Reflector | ||||

| Item No. | Length(mm) | Inner Hole Height (mm) | Inner Hole Length (mm) | Notes |

| AT-YHL-FS001 | 71.5 | / | / | Elliptical cavity |

| AT-YHL-FS002 | 92 | / | / | Elliptical cavity |

| AT-YHL-FS003 | 101 | 14.5 | 30 | Elliptical with Single lamp single rod |

| AT-YHL-FS004 | 100 | 17 | 45 | Elliptical with Double lamp single rod |

| AT-YHL-FS005 | 130 | 17 | 45 | Elliptical with Double lamp single rod |

| AT-YHL-FS006 | 150 | 17 | 45 | Elliptical with Double lamp single rod |

| AT-YHL-FS007 | 160 | 17 | 45 | Elliptical with Double lamp single rod |

| AT-YHL-FS008 | 170 | 17 | 45 | Elliptical with Double lamp single rod |

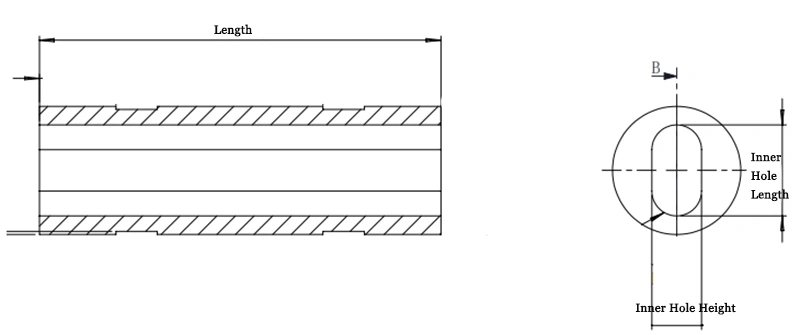

Type 2: Cylindrical alumina laser cavity liner

| Cylindrical alumina laser cavity liner | ||||

| Item No. | Length(mm) | Inner Hole Height (mm) | Inner Hole Length (mm) | Notes |

| AT-YHL-FS009 | 64 | 8 | 16.5 | Cylinder with Single lamp single rod |

| AT-YHL-FS010 | 89 | 9.3 | 19.3 | Cylinder with Single lamp single rod |

| AT-YHL-FS011 | 97 | 12 | 22 | Cylinder with Single lamp single rod |

| AT-YHL-FS012 | 97 | 15 | 27.7 | Cylinder with Single lamp single rod |

| AT-YHL-FS013 | 97 | 12 | 22 | Cylinder with Single lamp single rod |

| AT-YHL-FS014 | 100 | 14.4 | 28.4 | Cylinder with Single lamp single rod |

| AT-YHL-FS015 | 100 | 17 | 32 | Cylinder with Single lamp single rod |

| AT-YHL-FS016 | 100 | 18 | 34 | Cylinder with Single lamp single rod |

| AT-YHL-FS017 | 115 | 12 | 22 | Cylinder with Single lamp single rod |

| AT-YHL-FS018 | 117 | 12 | 22 | Cylinder with Single lamp single rod |

| AT-YHL-FS019 | 120 | 14.4 | 28.4 | Cylinder with Single lamp single rod |

| AT-YHL-FS020 | 120 | 16 | 43 | Cylinder with Double lamp single rod |

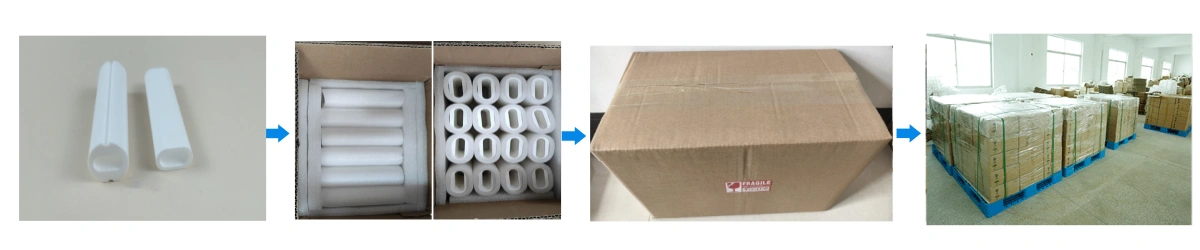

Alumina Ceramic Laser Reflector Packaging

- Foam-in-box with cavity protection; individual dust-free pouches.