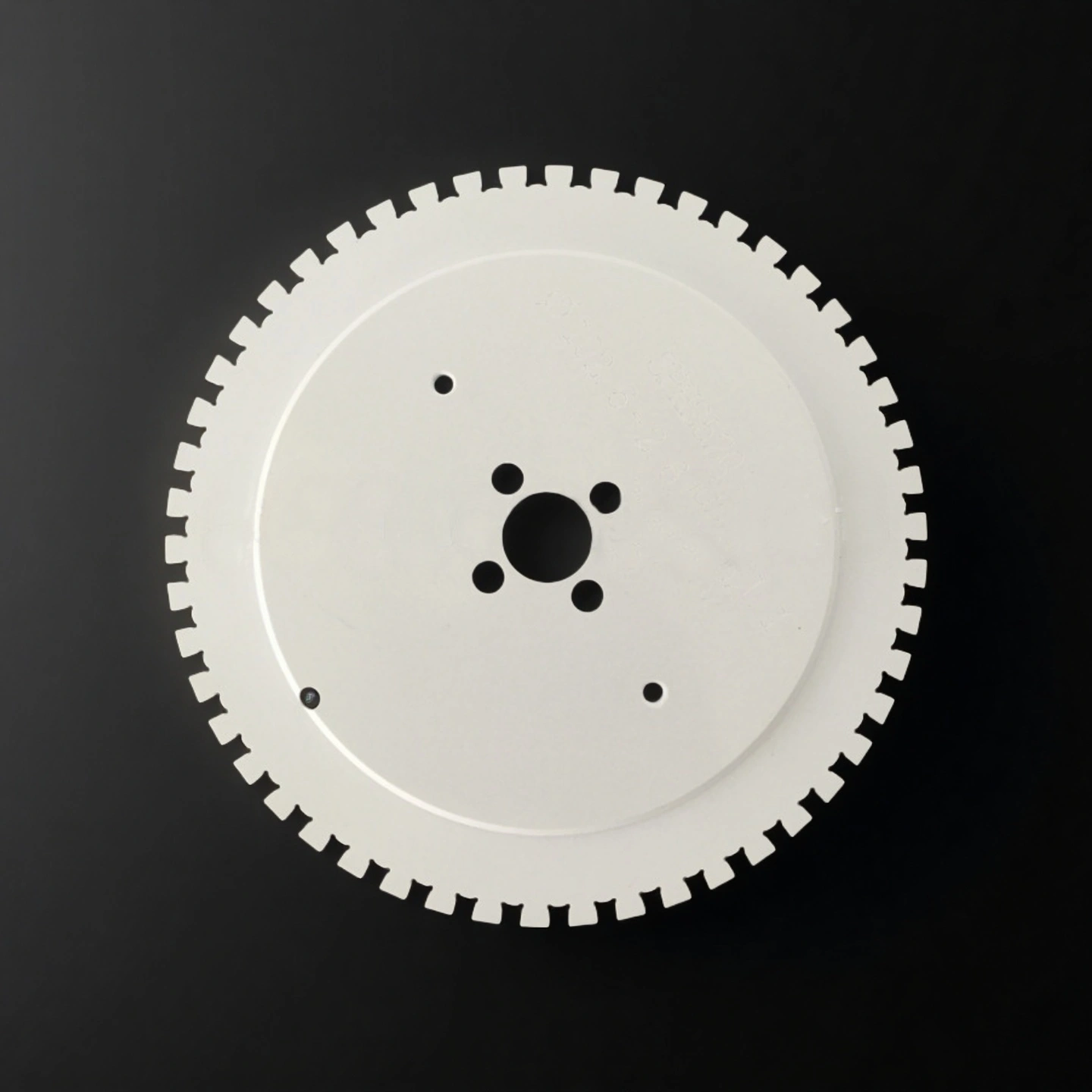

Alumina ceramic rotary indexing tables are designed for precise rotational positioning in high-precision equipment, including laser marking stations, CNC systems, and automated inspection platforms. Made from ≥95% alumina, the material offers exceptional hardness, dielectric strength, and thermal resistance, making it ideal for harsh industrial conditions or cleanroom environments.

Alumina Ceramic Rotary Indexing Table Benefits

-

Ceramic table plate integrated with rotary indexer

The working surface is a solid alumina ceramic disk bonded or mechanically fixed to the indexer, improving electrical insulation and surface stability compared with metal plates. -

Controlled flatness and runout for repeatable indexing

The ceramic table face is lapped or ground to controlled flatness and runout so parts locate consistently on every index step, supporting tight process capability on multi-station dials. -

High-temperature and chemically stable surface

High-purity alumina withstands repeated heating cycles and exposure to many process chemicals, which helps maintain indexing accuracy in laser processing, curing, or heating stations. -

Electrical insulation for test and high-voltage stations

The alumina ceramic table provides high dielectric strength and volume resistivity, isolating test probes and fixtures from the mechanical drive and frame during in-line electrical tests. -

Wear-resistant contact surface

The ceramic surface resists indentation and groove formation from repeated clamping or fixture contact, helping to maintain position accuracy across millions of indexing cycles.

Alumina Rotary Indexing Table Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Rotary Indexing Table Specifications

| Alumina Rotary Indexing Table | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-YHL-IW01 | Customize | |

Alumina Rotary Indexing Table Packaging

- Each alumina ceramic rotary indexing table plate is individually wrapped in soft protective film to prevent surface scratches.