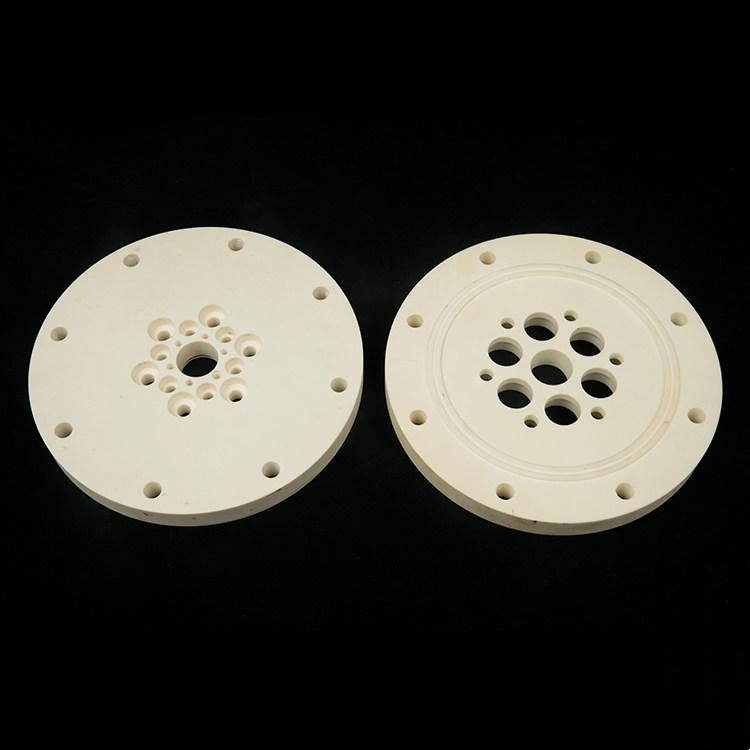

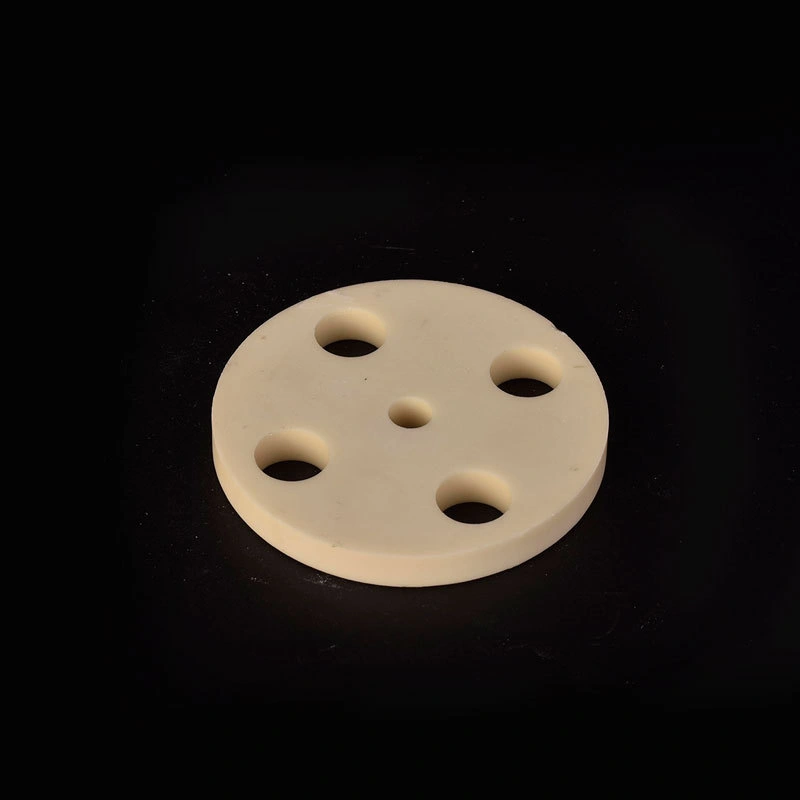

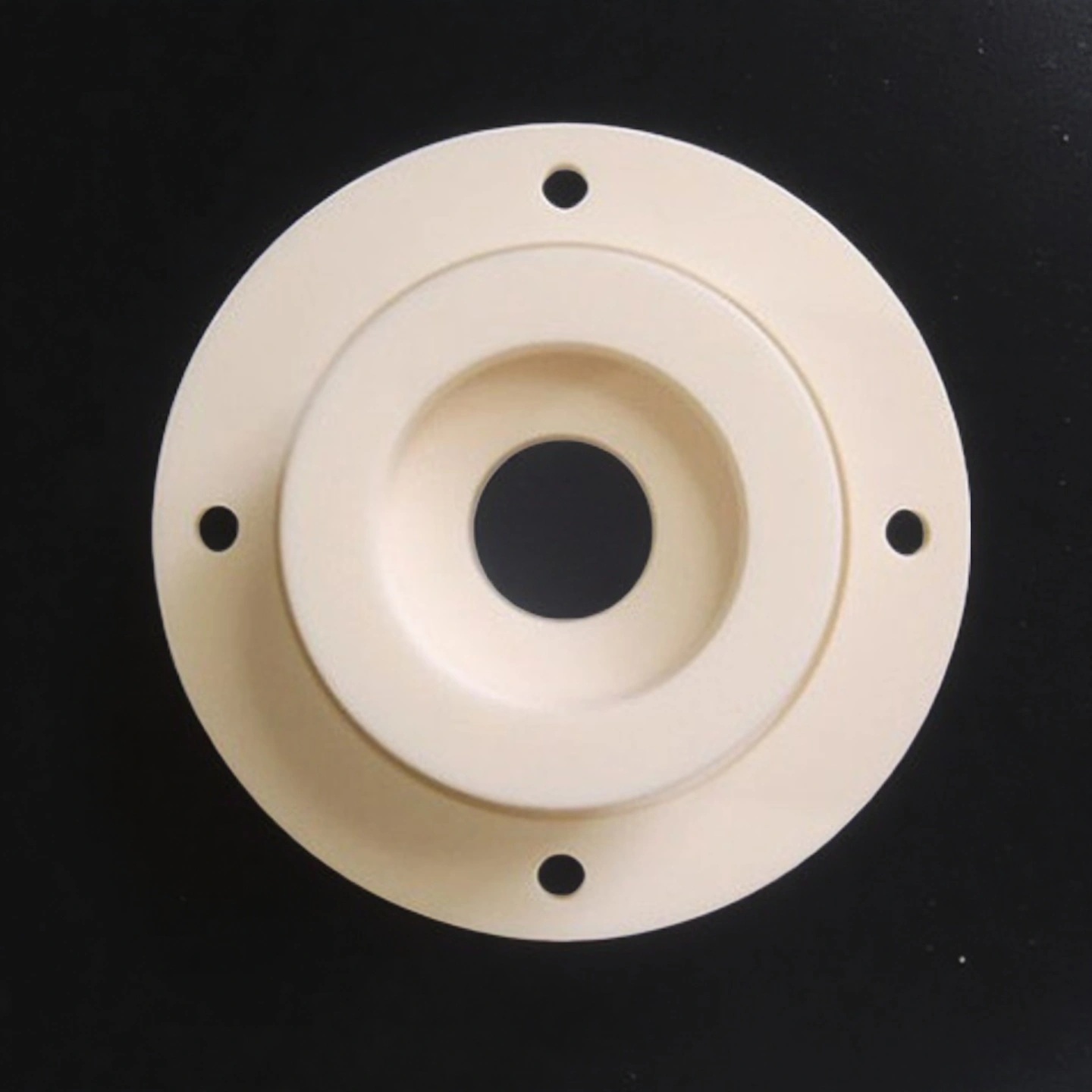

An alumina ceramic flange is a dense aluminum oxide (Al₂O₃) structural part designed to connect tubes, chambers and housings in high-temperature, vacuum or corrosive systems while providing electrical insulation and a stable sealing surface. It is typically made from 95–99.5% alumina engineering ceramic.

Alumina Ceramic Flange Benefits

-

Matched thermal expansion for high-temperature seals

The alumina ceramic flange uses dense Al₂O₃ with a controlled thermal expansion coefficient around 7–8.5 ×10⁻⁶ /°C, which helps maintain sealing contact and dimensional stability in 800–1400°C continuous service. -

High electrical insulation for vacuum and power feedthrough areas

The material offers very high volume resistivity and dielectric strength, making the flange suitable around heaters, electrodes and sensor lines that pass through vacuum or controlled atmosphere. -

Dense, corrosion-resistant ceramic contact surfaces

Fully dense alumina ceramic resists many acids, alkalis and process gases, reducing metal corrosion at tube connections and helping keep process atmospheres clean in chemical or thermal treatment equipment. -

Rigid support for tubes and chambers

The high hardness and compressive strength of alumina allow each flange to support tube loads and gasket compression without plastic deformation, improving alignment and reducing re-tightening over time. -

Compatible with multiple sealing concepts

The flange face can be made flat, stepped or grooved to accept graphite gaskets, fiber gaskets or metal seals, so users can integrate alumina ceramic flanges into existing furnace and vacuum hardware standards.

Properties of Alumina Ceramic Flange

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Ceramic Flange Specifications

| Alumina Ceramic Flange | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-YHL-FL01 | Customize | |

Alumina Ceramic Flange Packaging

- Each alumina ceramic flange is wrapped in soft cushioning material to avoid chipping on edges and bolt holes.