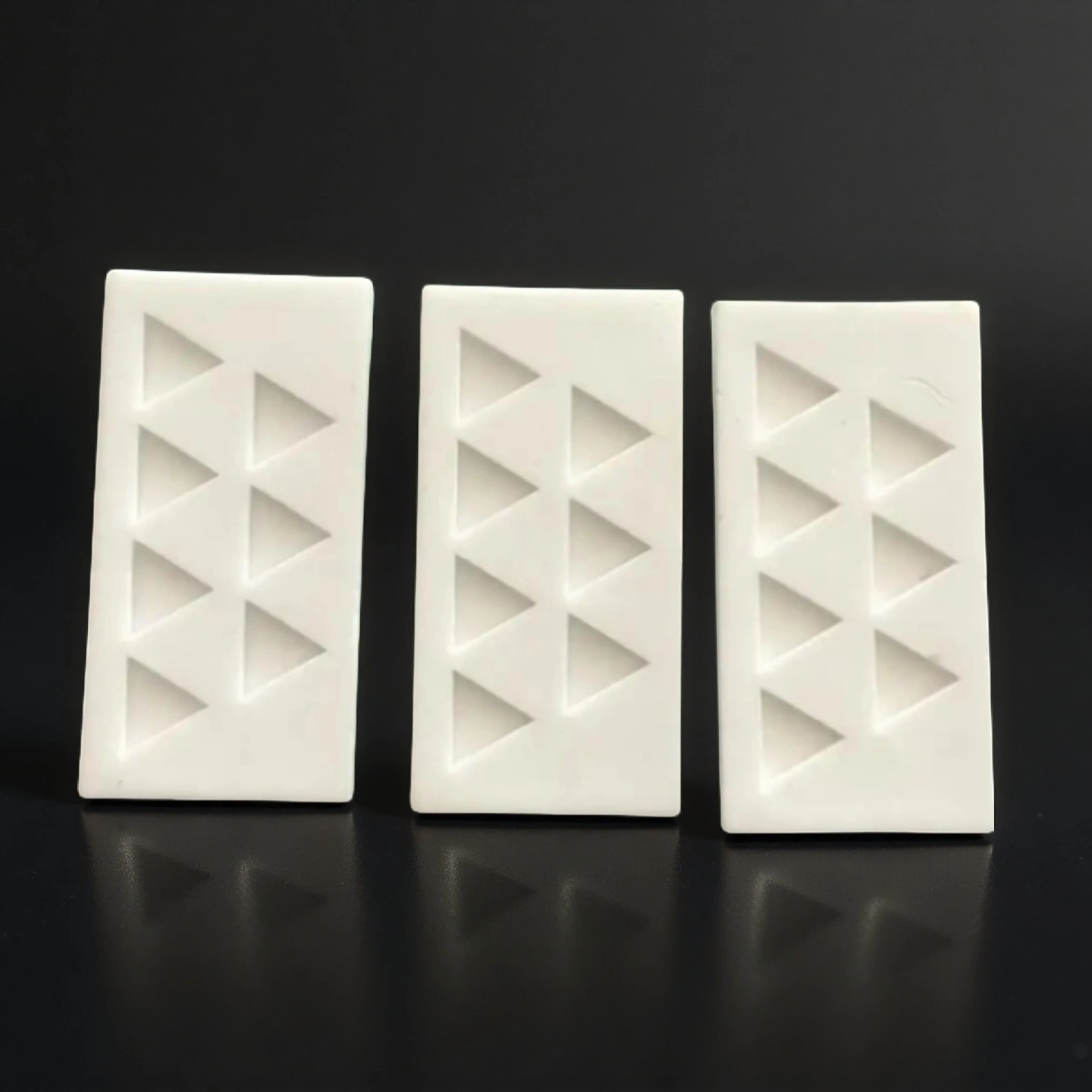

Alumina Ceramic Ash Boats are specialized laboratory and industrial containers made from high-purity aluminum oxide (Al₂O₃). They are designed to hold solid samples during ashing, combustion, or thermal analysis processes, where materials are heated to very high temperatures to determine ash content, remove organics, or prepare samples for further testing.

Alumina Ceramic Ash Boats Benefits

- Withstands extreme heat without warping, enabling stable combustion cycles

- Maintains chemical purity to avoid contamination during analysis

- Precision dimensions ensure compatibility with laboratory furnaces and analysers

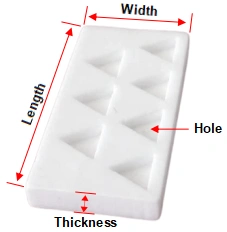

Alumina Ceramic Ash Boats Specifications

| Square Alumina Crucible Boats | ||||

| Item NO. | Hole | Length(mm) | Width(mm) | Thickness(mm) |

| AT-A-56-1 | 2 | / | / | / |

| AT-A-56-2 | 3 | 44 | 21 | 4 |

| AT-A-56-3 | 3 | 44 | 22 | 4 |

| AT-A-56-4 | 4 | 55 | 30 | 4 |

| AT-A-56-5 | 5 | 55 | 30 | 4 |

| AT-A-56-6 | 5 | 47 | 20 | 4 |

| AT-A-56-7 | 7 | 40 | 20 | 2 |

| AT-A-56-8 | 7 | 55 | 30 | 4 |

| AT-A-56-9 | 7 | 55.5 | 30 | 6 |

| AT-A-56-10 | 10 | 53 | 24 | 6 |

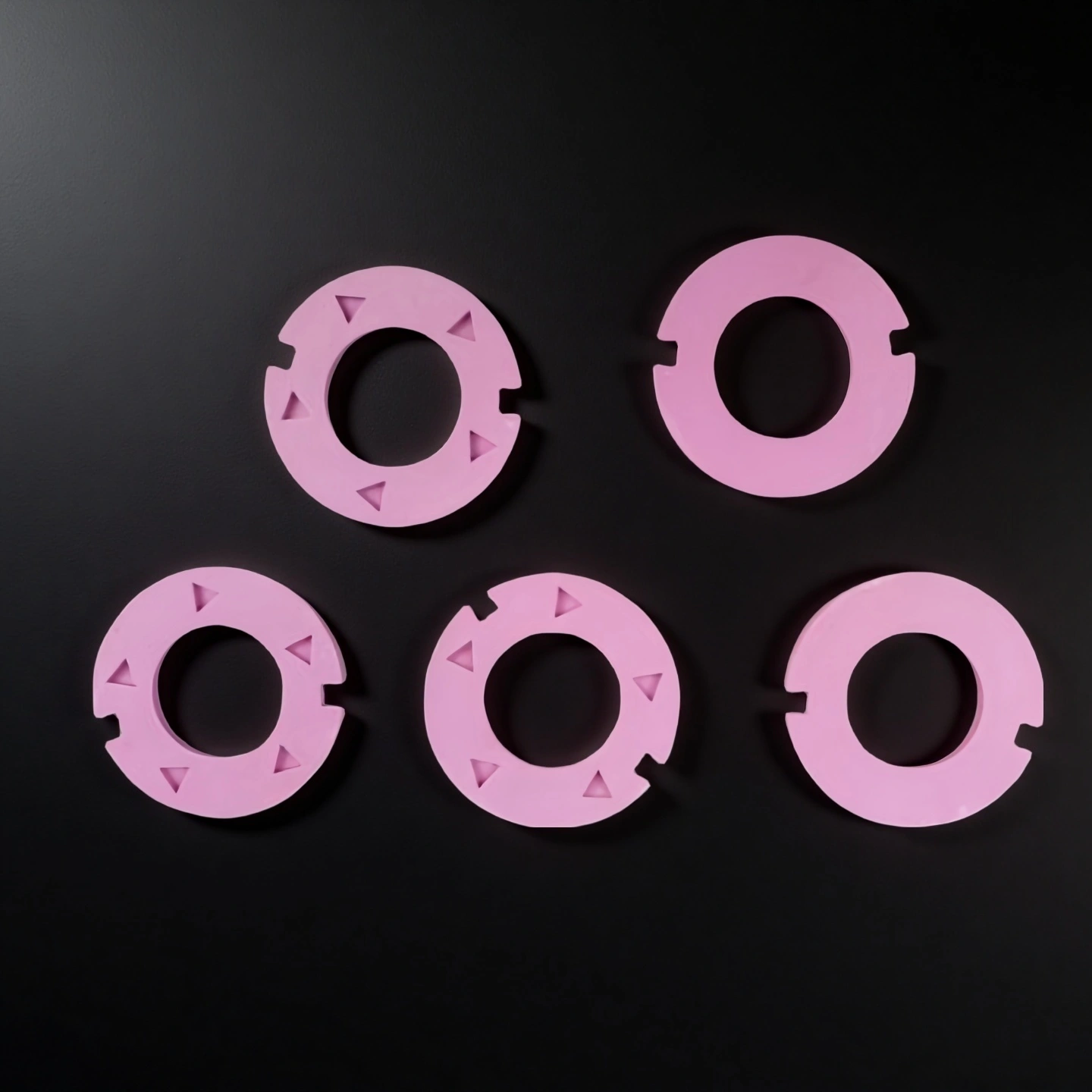

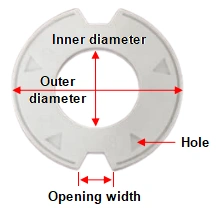

| Round Alumina Crucible Boats | |||||

| Item NO. | Hole | Outer diameter (mm) | Inner diameter(mm) | Thickness(mm) | Opening width(mm) |

| AT-A-56-11 | 5 | 58 | 30 | 4 | / |

| AT-A-56-12 | 5 | 58 | 30 | 4 | 5 |

| AT-A-56-15 | 15 | 80 | 50 | 6 | / |

| AT-A-56-16 | 15 | 80 | 50 | 6 | 5 |

*Note: The table above shows only some standard specifications. For more specifications, please refer to the complete product catalogue or contact us for customization.

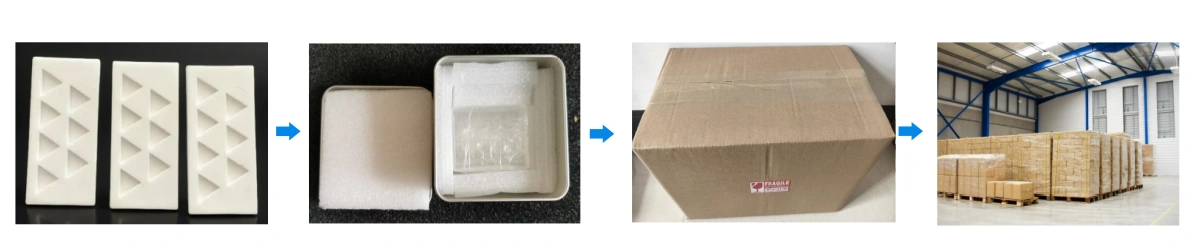

Alumina Ceramic Ash Boats Packaging

- Each alumina boat is individually foam-packed and boxed.