Black zirconia ceramic is a partially stabilized zirconium oxide engineered to deliver high strength and toughness in demanding industrial environments. The material also offers superior surface stability and dimensional control for tight-tolerance integration.

Black Zirconia Ceramic Benefits

- High fracture toughness prevents failure in rotary shaft and pump seal applications.

- The black color ensures visual contrast in automated systems for detection and alignment.

- Chemically inert surface – withstands acids, alkalis, and oxidizing environments.

- Low coefficient of thermal expansion – ideal for thermal cycling devices.

- Electrically insulating and corrosion-resistant – suitable for sensor, aerospace, and lab applications.

Black Zirconia Ceramic Specifications

| Black Zirconia Rod | ||

| Item No. | Length(mm) | Width(mm) |

| AT-HG-B1001 | Customize | |

| Black Zirconia Ceramic Pin | ||

| Item No. | Length(mm) | Width(mm) |

| AT-HG-X1001 | Customize | |

| Black Zirconia Ceramic Ring | ||

| Item No. | Length(mm) | Width(mm) |

| AT-HG-H1001 | Customize | |

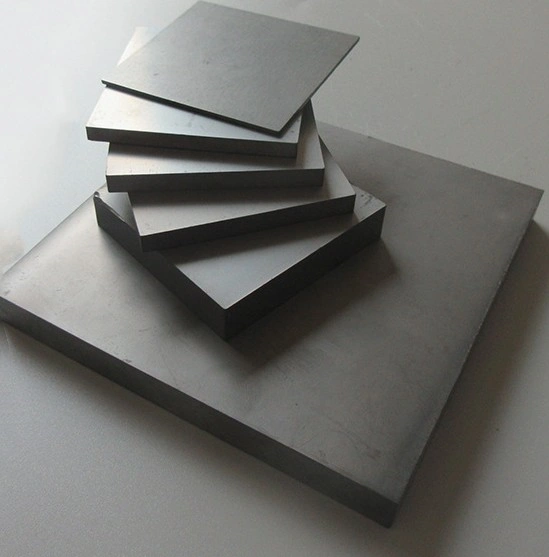

| Black Zirconia Ceramic Substrate | ||

| Item No. | Length(mm) | Width(mm) |

| AT-HG-J1001 | Customize | |

Packing:

- Standard Unit: Individually bubble-packed in anti-static PE sleeves

- Batch Pack: Vacuum blister trays for smaller parts or bulk foam boxes for large components