ADCERAX® Silicon Carbide Thrust Ring is a structural ceramic component designed for axial stability in pumps, mechanical seals, and vacuum systems where long‑term reliability is essential. Its RBSC or SSiC material provides strength, thermal resistance, and chemical durability that support consistent performance in corrosive or high‑load industrial environments. These characteristics allow the component to maintain stable axial alignment, reducing equipment wear and helping users achieve dependable operation across demanding fluid‑handling applications.

Key Features of Silicon Carbide Thrust Ring

- High Mechanical Stability Supported by Verified Material Strength

• The material offers flexural strength between 350–500 MPa, allowing the ring to remain stable during continuous operation in pump and seal systems. This strength level reduces displacement risk in equipment running at 3,600–15,000 RPM.

• Its hardness rating of HRA 90–94 ensures wear resistance during rotation and reduces contact degradation in abrasive or slurry environments. This performance helps extend equipment service intervals when handling solids-laden fluids.

• Thermal conductivity between 120–160 W/m·K helps stabilize temperature distribution at the contact interface. This reduces thermal stress during fluctuating operating conditions above 200°C.

- Chemical Durability in Corrosive and High‑Moisture Environments

• The material maintains chemical resistance against acids, bases, and salt solutions, verified through long-term exposure tests using pH 1–14 media. This supports stable operation for pumps handling corrosive chemical streams.

• The ring remains dimensionally consistent in high-humidity environments, preventing degradation in systems exposed to over 90% relative humidity. This reliability helps maintain equipment uptime in coastal, marine, or wet-process facilities.

• Its corrosion‑resistant behavior supports long-term use in slurry systems containing 10–30% particulate concentration. This helps reduce surface attack and mechanical erosion during constant circulation.

- Dimensional Precision Supporting Critical Axial Alignment

• The ring surface can be manufactured to roughness values of Ra 0.02–0.8 μm, enabling stable contact behavior in high-speed mechanical interface systems. This surface performance helps prevent friction-related micro‑movement.

• Its low thermal expansion rate of 4.2–4.4 × 10⁻⁶/K allows it to maintain fitment stability during temperature cycles from –50°C to +220°C. This stability supports accurate alignment in systems with frequent heating and cooling.

• Material density between 3.03–3.10 g/cm³ enhances structural integrity during axial loading. This density range provides predictable behavior in vacuum pumps, chemical pumps, and bearing assemblies.

Technical Specifications of Silicon Carbide Thrust Ring

ADCERAX® Silicon Carbide Thrust Ring demonstrates stable mechanical, thermal, and chemical behavior under demanding industrial conditions, supported by RBSC and SSiC ceramic structures that deliver consistent performance across varied load, temperature, and fluid environments.

| Property |

Specification |

| Material Type |

RBSC / SSiC |

| Density |

3.03–3.10 g/cm³ |

| Hardness |

HRA 90–94 |

| Flexural Strength |

350–500 MPa |

| Thermal Conductivity |

120–160 W/m·K |

| Thermal Expansion Coefficient |

4.2–4.4 × 10⁻⁶/K |

| Operating Temperature Range |

–50°C to +220°C |

| Chemical Resistance |

Acid / alkali / salt‑solution stable |

| Electrical Behavior |

Semi‑conductive ceramic profile |

| Surface Roughness Capability |

Ra 0.02–0.8 μm |

| Microstructure |

Fine‑grain SiC matrix (laboratory verifiable) |

Dimensions of Silicon Carbide Thrust Ring

|

SiC Thrust Ring |

|

Item No. |

Diameter(mm) |

Height (mm) |

|

AT-SIC-TH1001 |

Customize |

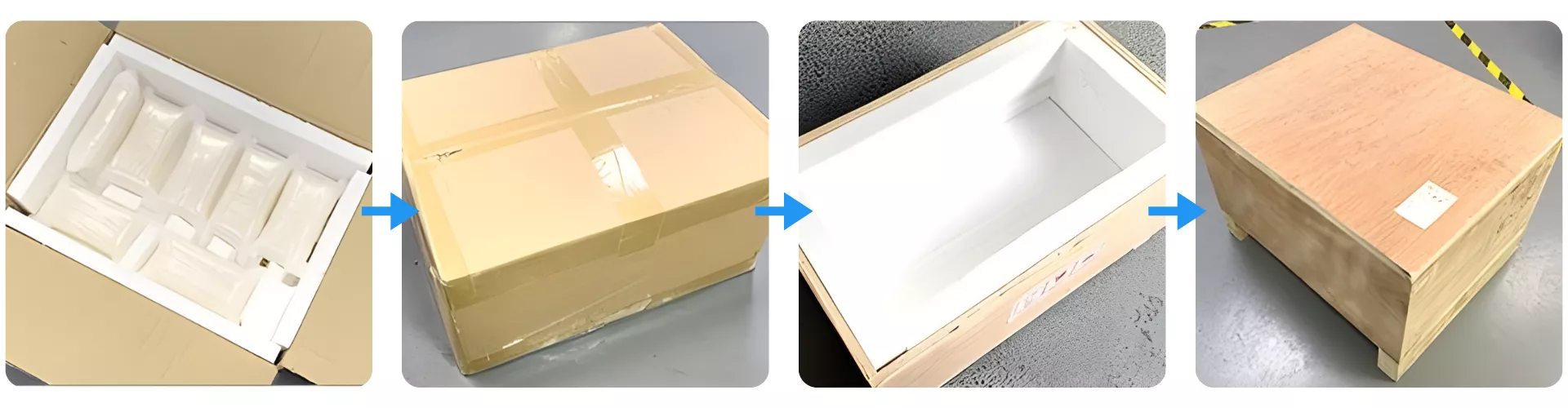

Packaging Method for Silicon Carbide Thrust Ring

Silicon Carbide Thrust Ring shipments are protected using layered cushioning inside a reinforced carton to prevent impact during transport. The sealed carton is then placed into a foam‑lined wooden crate for added structural support. This combination ensures stable handling and safe arrival of the ceramic components under long‑distance international shipping conditions.

ADCERAX® Uses the Silicon Carbide Thrust Ring to Improve Reliability in High‑Demand Industrial Systems

The Silicon Carbide Thrust Ring plays a critical role in equipment exposed to continuous rotation, aggressive fluids, abrasive slurries, and fluctuating thermal loads. By addressing alignment, wear, and corrosion challenges in real industrial environments, ADCERAX® provides rings engineered to maintain stable axial behavior where conventional metallic or oxide‑based components fail.

-

Slurry Transfer Pumps in Mineral Processing Using Silicon Carbide Thrust Ring

✅Key Advantages

1. Abrasive‑Stable SiC Microstructure

The fine‑grain SSiC matrix resists high‑energy particle impact from slurry streams with solid concentrations up to 40%. This stability minimizes axial drift caused by cumulative erosive force over continuous pump cycles.

2. Surface Integrity Under High‑Velocity Slurry Flow

The ring maintains structural consistency when exposed to slurry flow speeds reaching 6 m/s, where metallic components typically exhibit rapid surface fatigue. This allows shafts to retain alignment through prolonged abrasive contact.

3. Chemical Compatibility With pH‑Adjusted Slurries

The SiC surface remains inert across slurry chemistries ranging from pH 1 to pH 12, preventing chemical softening that contributes to misalignment. This enables sustained performance during mineral conditioning and flotation processes.

✅ ️Problem Solved

In mineral processing circuits, operators frequently encounter premature thrust‑ring degradation due to the combined mechanical erosion and chemical action of abrasive slurries. Maintenance logs often show axial misalignment occurring after only moderate run time because metallic rings deform or pit under solid‑rich conditions. A mine‑site customer using slurry transfer pumps reported repeated shaft instability triggered by erosion around axial bearing components. After adopting the ADCERAX® Silicon Carbide Thrust Ring, the pump maintained stable axial control through extended intervals with slurry concentrations above 30% solids, reducing unscheduled maintenance events. This demonstrated that the SiC ring’s abrasion‑resistant and chemically inert structure can sustain alignment in circuits where conventional components fail prematurely.

-

Desalination and Seawater Intake Pumps Using Silicon Carbide Thrust Ring

✅Key Advantages

1. Resistance to Chloride‑Driven Pitting and Surface Breakdown

The SiC surface maintains structural uniformity in seawater containing chloride levels around 35,000 ppm, preventing pitting that destabilizes metallic rings. This preserves the smooth axial interface required for long‑duration intake pumping.

2. Dimensional Stability Across Thermal Swings

Low expansion values of 4.2–4.4 × 10⁻⁶/K prevent shift in axial positioning during fluctuations between cold intake water and warmer pump housings. This helps avoid vibration events linked to heat‑related deformation in marine systems.

3. Non‑Reactive Behavior in Bio‑Element and Oxygen Exposure

Silicon carbide does not react with dissolved oxygen or biological matter found in coastal water, avoiding the surface film formation seen on metal components. This maintains consistent shaft alignment during continuous seawater circulation.

✅ ️Problem Solved

In desalination facilities, repeated exposure to saline water and dissolved oxygen gradually weakens metallic thrust components, introducing small alignment deviations that reduce pump efficiency. A coastal intake station experienced progressive shaft instability due to pitting and surface roughening caused by long‑term seawater circulation. Engineers noted increasing vibration during extended duty cycles as metallic rings lost their structural integrity. After switching to the ADCERAX® Silicon Carbide Thrust Ring, axial stability remained consistent through continuous operation with seawater salinity around 35,000 ppm, with no evidence of pitting or mechanical drift. This allowed the pump to retain operational efficiency and improved reliability under harsh marine conditions.

-

High‑Vacuum Chemical Vapor Transport Systems Using Silicon Carbide Thrust Ring

✅Key Advantages

1. Low‑Outgassing Surface for Stable Vacuum Operation

The SiC ring maintains surface purity under vacuum levels down to 10⁻³ mbar, preventing molecular release that disrupts chamber pressure. This ensures clean axial movement without pressure fluctuation.

2. Inertness to Reactive Vapors and Residual Chemicals

The SSiC structure avoids reaction with condensable species or organic vapors commonly present in chemical transport lines. This prevents surface alteration or particle generation that harms vacuum pump mechanisms.

3. Precision Behavior Under Low‑Pressure Mechanical Load

High stiffness and density between 3.03–3.10 g/cm³ support stable axial movement despite the amplification of mechanical disturbances in vacuum conditions. This avoids micro‑deflection that causes premature wear in precision systems.

✅ ️Problem Solved

Vacuum transport systems often suffer performance instability when thrust components deform or release contaminants under reactive vapor exposure. One chemical processing user found that polymer‑reinforced rings produced outgassing and surface degradation, causing axial variation that interrupted vacuum continuity. Residual vapor contact accelerated the deterioration of these components, leading to irregular motion inside the pump assembly. After implementing the ADCERAX® Silicon Carbide Thrust Ring, the system sustained stable axial control even under pressures approaching 10⁻³ mbar, with no detectable surface degradation or outgassing events. This improved the consistency of the vacuum environment and eliminated the mechanical interruptions previously observed.

ADCERAX® Silicon Carbide Thrust Ring User Guide for Safe and Consistent Operation

The Silicon Carbide Thrust Ring from ADCERAX® functions in environments involving rotation, load, temperature change, and direct fluid contact, so users benefit from clear operational guidance to maintain stability and prolong service life. The following recommendations help ensure proper installation, handling, inspection, and long‑term care of this ceramic component across diverse industrial systems.

-

Installation Preparation Requirements

1. Before installing the component, verify that all mating surfaces in the equipment are clean, flat, and free of foreign particles to avoid disturbance of axial alignment. Confirm that the surrounding assembly is structurally sound and capable of supporting the ceramic component’s stiffness under operational load. Review the equipment design drawings to ensure that the ring is positioned in the correct orientation within the axial housing.

2. Ensure the assembly area maintains stable ambient conditions, avoiding sudden thermal variation that could cause stress during initial fitment. Users should avoid forcing the ring into tight spaces or applying uneven pressure that may affect structural integrity. Proper preparation minimizes the risk of micro‑movement once the system begins operating.

3. Check that compatible lubricants, sealants, or barrier fluids—if required by the system design—are chemically suitable for SiC surfaces, preventing unwanted interaction during startup. Maintain clean tools and consistent handling practices throughout the preparation stage. These practices support predictable performance when the equipment enters operation.

-

Correct Installation and System Integration

1. During installation, apply uniform loading pressure to seat the thrust ring securely in its axial position. Avoid striking or tilting the component, as ceramic structures rely on even contact distribution for precise performance. Ensure the ring engages correctly with the mechanical shaft or seal elements.

2. Once positioned, confirm that the axial clearance and rotational pathway remain unobstructed, enabling consistent movement once operational flow begins. System components that interact with the ring should move freely without inducing irregular point contact. Proper alignment helps reduce unnecessary friction.

3. After installation, conduct a controlled startup cycle, monitoring for vibration, noise, or temperature rise that may indicate misalignment. Maintain careful observation during the first operational hours to verify stabilization. This step ensures that the thrust ring integrates correctly into the broader mechanical structure.

-

Routine Inspection and Performance Monitoring

1. Establish a periodic inspection schedule that includes examining the ring for surface wear, discoloration, or uneven contact along the axial surface. Any abnormal pattern may indicate external mechanical loading issues. Regular checks enable early intervention.

2. Monitor system behavior such as vibration trends, temperature changes, or fluid characteristics to detect conditions that may accelerate wear. Abnormal performance in surrounding components often impacts the thrust ring’s stability. Maintaining reference logs supports accurate diagnosis.

3. Inspect supporting hardware—including shafts, housings, and seals—for consistent condition and alignment. Even slight deviations in adjacent components may influence the ceramic ring’s long‑term behavior. Identifying early signs of stress helps prevent extended downtime.

-

Handling, Cleaning, and Storage Practices

1. Handle the ring with care, using clean, non‑abrasive gloves to avoid contamination of the ceramic surface. Avoid dropping, striking, or dragging the component across hard materials. These precautions reduce the risk of micro‑damage.

2. When cleaning, use neutral agents that do not chemically interact with SiC, and rinse thoroughly to prevent residue buildup. Avoid aggressive scrubbing that may affect surface characteristics. Proper cleaning maintains performance consistency.

3. Store the component in a controlled location protected from moisture, dust, and sudden temperature change. Maintain separation from metallic parts or tools that could transfer impact load. Proper storage supports long‑term readiness before installation.

![]()