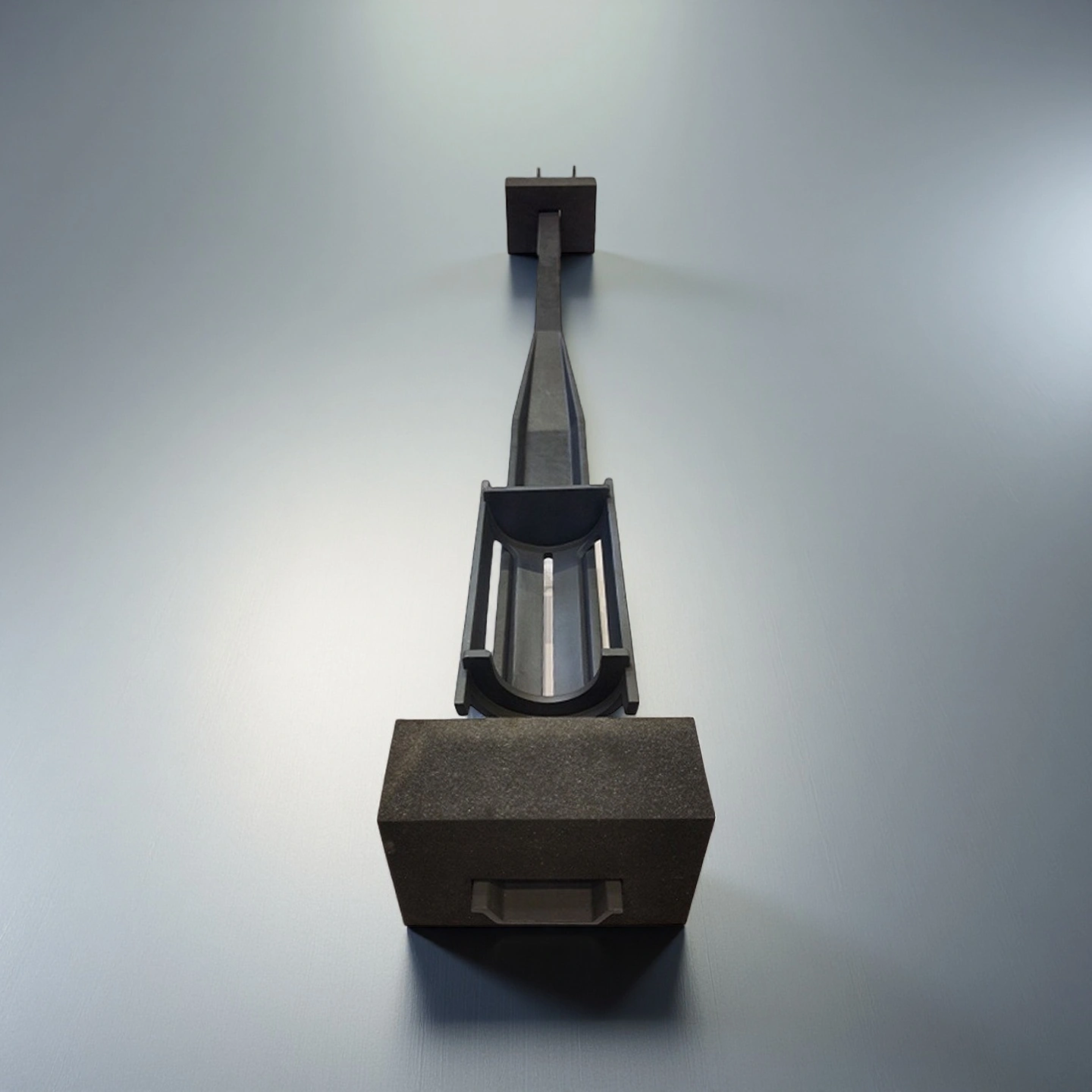

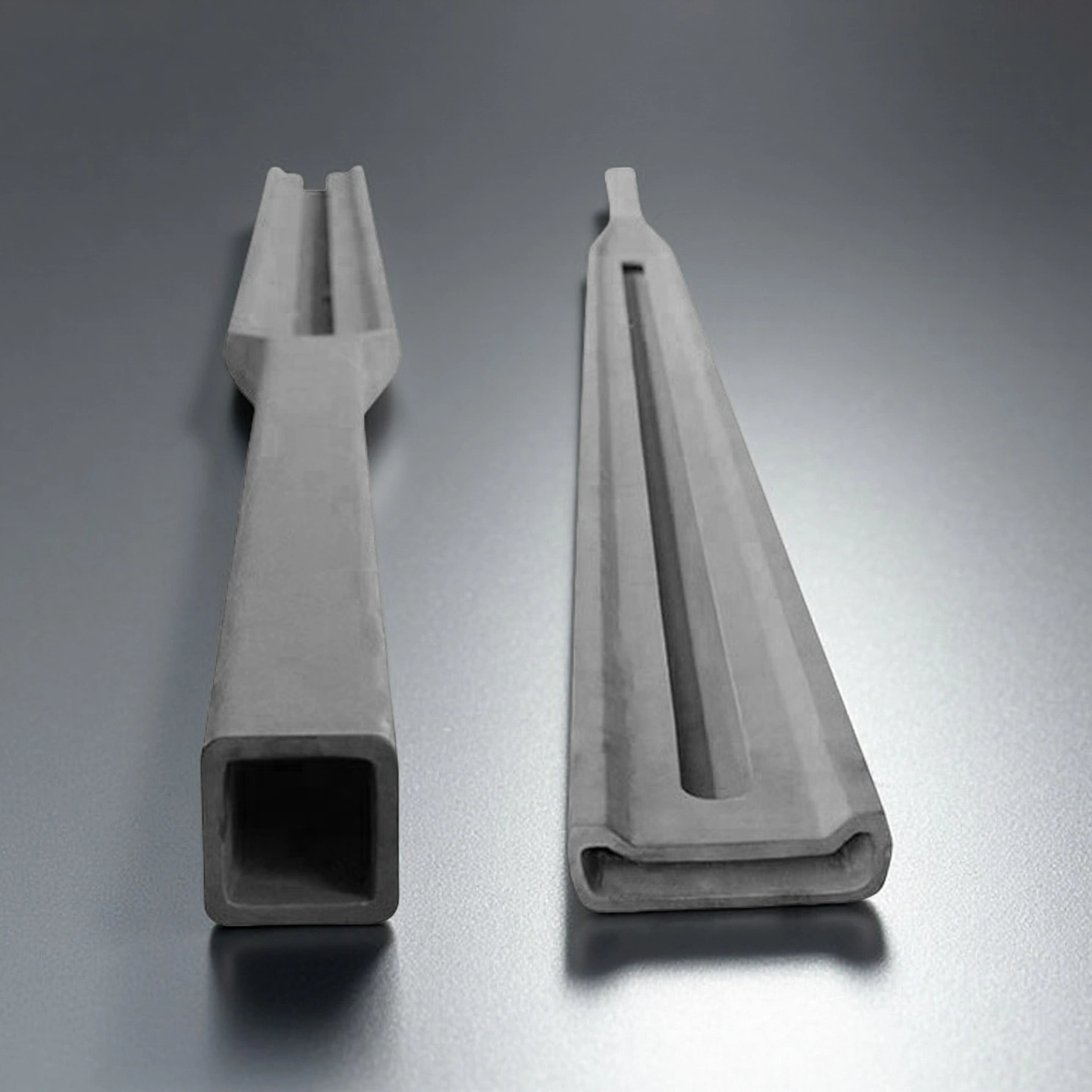

ADCERAX® Silicon Carbide Cantilever Paddle is engineered for stable wafer handling and high-temperature material transfer inside diffusion, oxidation, and epitaxy furnace systems, where consistent thermal behavior and mechanical reliability are essential. Its RBSiC or SSiC composition supports controlled heat distribution and long-span structural stability, enabling predictable operation across demanding thermal cycles while functioning as a SiC Cantilever Paddle within continuous production environments. The paddle maintains low particle generation and corrosion resistance in mixed atmospheres, allowing it to serve reliably as a Silicon Carbide Diffusion Paddle for facilities seeking clean, repeatable, and contamination-controlled furnace performance.

Key Features of Silicon Carbide Cantilever Paddle

-

High-Temperature Stability for Continuous Furnace Operation

The paddle maintains structural reliability under >1400°C continuous temperature exposure, ensuring predictable handling behavior during long-duration diffusion or oxidation processes. Its thermal expansion remains controlled at ~4.0 × 10⁻⁶/K, reducing positional drift across multi-zone heating cycles and supporting consistent wafer alignment under high thermal loads. The fine-grain SiC microstructure provides stable heat conduction with measured conductivity values exceeding 120 W/m·K, limiting temperature gradients across extended paddle spans.

-

Mechanical Strength to Support Long-Span Loading Demands

Flexural strength values ranging from 250–400 MPa enable the paddle to resist bending deformation during heavy wafer stack handling and repeated thermal cycling. Its elastic modulus, measured at >380 GPa, minimizes deflection under dynamic loading typical of diffusion furnace transfer movements. Wear resistance testing across >500 operational cycles demonstrates stable surface performance with limited microcrack propagation, supporting long service intervals in high-temperature environments.

-

Chemical and Atmospheric Resistance for Clean Processing

The paddle maintains inert behavior in oxidizing gases such as O₂ and inert gases including N₂ and Ar, with corrosion stability verified in environments above 1200°C. Its microstructure shows <1% closed porosity, reducing contamination pathways and preventing particle release during furnace loading sequences. Chloride-bearing gas compatibility has been validated through exposure tests exceeding 100 hours, ensuring reliable surface integrity in mixed-atmosphere processing commonly associated with Silicon Carbide Diffusion Paddle applications.

Technical Specifications of Silicon Carbide Cantilever Paddle

The Silicon Carbide Cantilever Paddle demonstrates stable thermomechanical performance, controlled microstructural behavior, and high reliability under extended high-temperature furnace conditions. Its material characteristics, atmospheric compatibility, and mechanical stability support demanding diffusion, oxidation, epitaxy, and sintering environments where consistent thermal response and structural rigidity are required.

| Property |

Specification |

| Density |

3.00–3.15 g/cm³ |

| Closed Porosity |

<1% |

| Thermal Conductivity |

>120 W/m·K |

| Thermal Expansion Coefficient |

~4.0 × 10⁻⁶/K |

| Continuous Operating Temperature |

≥1400°C |

| Short-Term Temperature Limit |

1600–1700°C |

| Flexural Strength |

250–400 MPa |

| Elastic Modulus |

>380 GPa |

| Surface Hardness |

>22 GPa |

| Chemical Stability (O₂/N₂/Ar) |

Stable to >1200°C |

| Chloride Gas Compatibility |

>100 h exposure stability |

| Thermal Shock Resistance |

High; validated in rapid cycle testing |

| Wear Resistance |

>500 cycles with minimal degradation |

| Microstructure |

Fine-grain SiC with uniform distribution |

Dimensions of Silicon Carbide Cantilever Paddle

|

Silicon Carbide Cantilever Paddle |

|

Item No. |

Diameter(mm) |

Height (mm) |

|

AT-SIC-XJ1001 |

Customize |

Packaging & Protection for Silicon Carbide Cantilever Paddle

Silicon Carbide Cantilever Paddle packaging is arranged using reinforced wooden crates with internal foam partitioning to prevent vibration and edge impact during transport. Each unit is individually wrapped, boxed, and secured with multi-layer strapping to maintain stability through long-distance freight. The final palletized assembly provides additional load integrity, ensuring safe arrival for installation in photovoltaic furnace lines.

Solving Application Challenges with ADCERAX® Silicon Carbide Cantilever Paddle

The ADCERAX® Silicon Carbide Cantilever Paddle addresses critical operational constraints in high-temperature photovoltaic processing lines by stabilizing wafer transport, minimizing contamination, and ensuring predictable thermal performance during demanding diffusion and oxidation cycles.

-

Precision Wafer Support in High-Temperature PV Diffusion Furnaces

✅Key Advantages

1. Controlled Long-Span Deflection

In high-temperature PV diffusion zones, the ADCERAX® Silicon Carbide Cantilever Paddle limits vertical deflection to less than 0.2 mm over long spans under full wafer loading. This level of stiffness is enabled by a flexural strength in the 250–400 MPa range and an elastic modulus above 380 GPa, keeping wafer stacks stable through extended heating cycles.

2. Thermally Stable Wafer Alignment

The paddle’s SiC body exhibits a thermal expansion coefficient of approximately 4.0 × 10⁻⁶/K, which restricts in-plane dimensional change as the furnace ramps above 1400°C. This controlled expansion behavior reduces cumulative misalignment across multi-zone diffusion tubes, helping maintain consistent wafer-to-wafer spacing during dopant drive-in.

3. Uniform Heat Transfer Across Stacks

Fine-grain SiC microstructure and thermal conductivity above 120 W/m·K support even heat distribution from the cantilever surface into each wafer in the stack. Measured temperature variation at the wafer contact interface can be held within ±3°C across the loaded span, which contributes to narrower dopant profile variation and improved repeatability between batches.

✅ ️Problem Solved

A PV cell manufacturer operating multi-stack diffusion furnaces reported frequent wafer misalignment and bowing when using legacy carriers, with positional drift accumulating along the furnace length and causing measurable non-uniformity in sheet resistance. After replacing conventional carriers with ADCERAX® Silicon Carbide Cantilever Paddle assemblies, line audits showed that stack skew and tilt angles were reduced by more than 50% over typical production runs. Diffusion results indicated a tighter distribution of dopant depth across wafers from edge to center, and the rate of alignment-related line stops dropped to below 5% of previous incident frequency. This allowed the diffusion section to run longer between mechanical interventions while maintaining more stable electrical performance on finished cells.

-

Contamination-Free Handling for Oxidation and Annealing Lines

✅Key Advantages

1. Ultra-Low Porosity Contact Surface

The ADCERAX® Silicon Carbide Cantilever Paddle is manufactured with closed porosity below 1%, which limits gas entrapment and particle shedding during oxidation and annealing cycles. Surface inspection after extended operation in PV lines has shown a significant reduction in loose particulate compared with porous or coated carriers, improving cleanliness at the wafer interface.

2. Oxidation-Stable SiC Chemistry

In oxygen-rich environments above 1200°C, the SiC surface develops a thin, stable oxide that does not flake or spall under normal cycling conditions. Long-duration exposure tests exceeding 100 hours in O₂ and mixed O₂/N₂ atmospheres confirm that the paddle retains structural integrity and surface continuity, supporting consistent operation in oxidation and anneal furnaces.

3. Reduced Defect-Related Contamination Events

By avoiding carbon-based binders and unstable coatings, the paddle removes a common source of contamination that can generate recombination-active defects on wafer surfaces. PV process monitoring has shown that lines using silicon carbide carriers can lower contamination-triggered defect rates by 20–30% compared with graphite-based carriers in comparable oxidation regimes.

✅ ️Problem Solved

A crystalline silicon PV producer operating high-throughput oxidation and annealing lines experienced recurring surface defect patterns traced back to carrier-derived particles and unstable films from graphite fixtures. Quality control data indicated that a noticeable portion of wafers from each batch required rework or downgrading after oxygen-rich cycles, and defect mapping correlated hotspots to zones with highest carrier exposure. After transitioning the affected sections to ADCERAX® Silicon Carbide Cantilever Paddle handling, the number of contamination-correlated defects per batch decreased by more than 25%, and visual inspection found no evidence of flaking or residue from the paddles over several hundred cycles. The oxidation and anneal steps became more repeatable across shifts, and process engineers reported a marked reduction in time spent diagnosing furnace contamination issues.

-

Long-Span Thermal Loading in High-Throughput Firing & Anneal Lines

✅Key Advantages

1. Proven Thermal Shock Endurance

The ADCERAX® Silicon Carbide Cantilever Paddle is validated for more than 500 rapid firing and anneal cycles without measurable cracking or structural fatigue under standard PV line ramp rates. Thermal shock testing using fast temperature transitions demonstrates that the paddle maintains continuous load-bearing capability where many conventional carriers show early microcrack formation after a few hundred cycles.

2. High Modulus Against Dynamic Bending

With an elastic modulus above 380 GPa, the paddle resists bending forces generated by acceleration and deceleration events in automated conveyor systems. Measured dynamic deflection during simulated firing-line motion remains below 0.15 mm at representative line speeds, which reduces vibration-induced movement of wafer stacks and stabilizes handling across the entire carrier length.

3. Reduced Warping Over Fast Ramp Profiles

The combination of controlled expansion and high stiffness limits permanent warping after repeated high-speed thermal ramps. Post-cycle geometry checks typically show total out-of-plane distortion below 0.3 mm after extended operation, compared with significantly higher values often recorded for metallic or composite carriers in similar firing conditions.

✅ ️Problem Solved

A high-throughput PV facility increased firing line speed to raise capacity and observed a corresponding increase in carrier warping and early cracking on its existing fixtures, leading to more frequent unplanned stops and mechanical replacements. Line records revealed that conventional carriers began to show unacceptable deformation after only a few hundred cycles, and the resulting instability affected wafer support in the hottest firing zones. After implementing ADCERAX® Silicon Carbide Cantilever Paddle units in the most demanding sections, the plant recorded stable carrier geometry beyond 500 firing cycles, with out-of-plane warp remaining below the internal limit used by the engineering team. The incidence of carrier-related stoppages fell sharply, and firing temperature profiles could be maintained more consistently across the belt, supporting higher sustained throughput without compromising handling stability.

ADCERAX® Silicon Carbide Cantilever Paddle User Guide for Safe and Stable Operation

The Silicon Carbide Cantilever Paddle requires correct handling, installation, and maintenance to ensure stable performance throughout high-temperature PV diffusion, oxidation, and firing workflows. This guide provides operational recommendations that help users protect the paddle’s structural integrity, maintain consistent wafer support, and reduce unexpected furnace downtime.

-

Handling Practices for High-Temperature Stability

1. Use Controlled Lifting Support

Proper lifting tools should be used to distribute weight evenly along the paddle span during movement. Concentrated force applied to one point can introduce stress that accumulates over repeated handling cycles. Avoid gripping the paddle at unsupported ends, as this may lead to micro-deflection over time.

2. Maintain Clean Contact Surfaces

Surfaces must be kept free from debris before entering the furnace loading area to avoid introducing unwanted particles. Gentle air blow or non-abrasive wipes should be used to clean contact zones without scratching the SiC surface. Contaminated surfaces can increase wafer slip risk and reduce thermal uniformity.

3. Monitor Environmental Exposure

Sudden transitions from cold environments to hot loading zones should be prevented, as extreme temperature shocks can fatigue any ceramic surface. Operators should ensure the storage area and furnace feed area have moderate temperature difference. Avoid rapid, unconditioned transfers that may stress the material.

-

Installation Guidelines for Diffusion and Oxidation Furnaces

1. Verify Rail Alignment Before Placement

The support rails must remain parallel and level to prevent uneven loading across the paddle length. Misaligned rails may generate localized bending force during movement. Always perform a visual or gauge check during replacement cycles.

2. Position Load Evenly Across the Span

Wafer stacks or substrates should be placed in a balanced distribution to avoid one-side loading during heating. This improves long-term dimensional stability and reduces bending fatigue. Never cluster heavy substrates at one section of the paddle.

3. Confirm Clearance With Furnace Fixtures

Ensure that the paddle has appropriate clearance with quartz tubes and internal chambers to avoid friction during travel. Even minor rubbing may affect surface finish and introduce contamination. Install paddles only after ensuring all interfaces are free of obstruction.

-

Operational Care During Thermal Cycling

1. Control Ramp Rates During Startup

Furnace startup should follow calibrated heating ramps to help the paddle adapt to temperature gradients. Excessively fast heating can produce thermal shock regardless of material grade. Follow the equipment manufacturer’s recommended ramp profile.

2. Avoid Contact With Cold Fixtures After Heating

When removing the paddle from high-temperature zones, operators should prevent immediate contact with cold metal or unconditioned surfaces. This reduces unpredictable thermal contraction stresses. Allow gradual temperature equalization before handling.

3. Inspect for Early Signs of Fatigue

After extended use, the paddle should be checked for surface micro-marks, discoloration, or unexpected deformation. Regular inspections help detect early fatigue before it affects wafer processing. Replace parts that show visible structural change.

-

Storage, Cleaning, and Long-Term Maintenance

1. Use Dedicated Storage Racks

Paddles should be stored on padded, vibration-free racks designed to support their full length. Unsupported storage can gradually introduce sagging over time. Never stack paddles on top of each other.

2. Apply Non-Abrasive Cleaning Methods

Only soft, non-abrasive cleaning tools should be used to prevent surface grinding or accidental scratching. Chemical cleaning agents should be avoided unless confirmed compatible with SiC surfaces. Harsh abrasives can alter surface roughness and thermal behavior.

3. Implement Scheduled Condition Reviews

Facilities running continuous PV production should conduct fixed-interval reviews of all handling paddles. Monitoring cycle count and exposure history helps predict optimal replacement timeframes. Consistent recordkeeping extends overall service reliability.

![]()