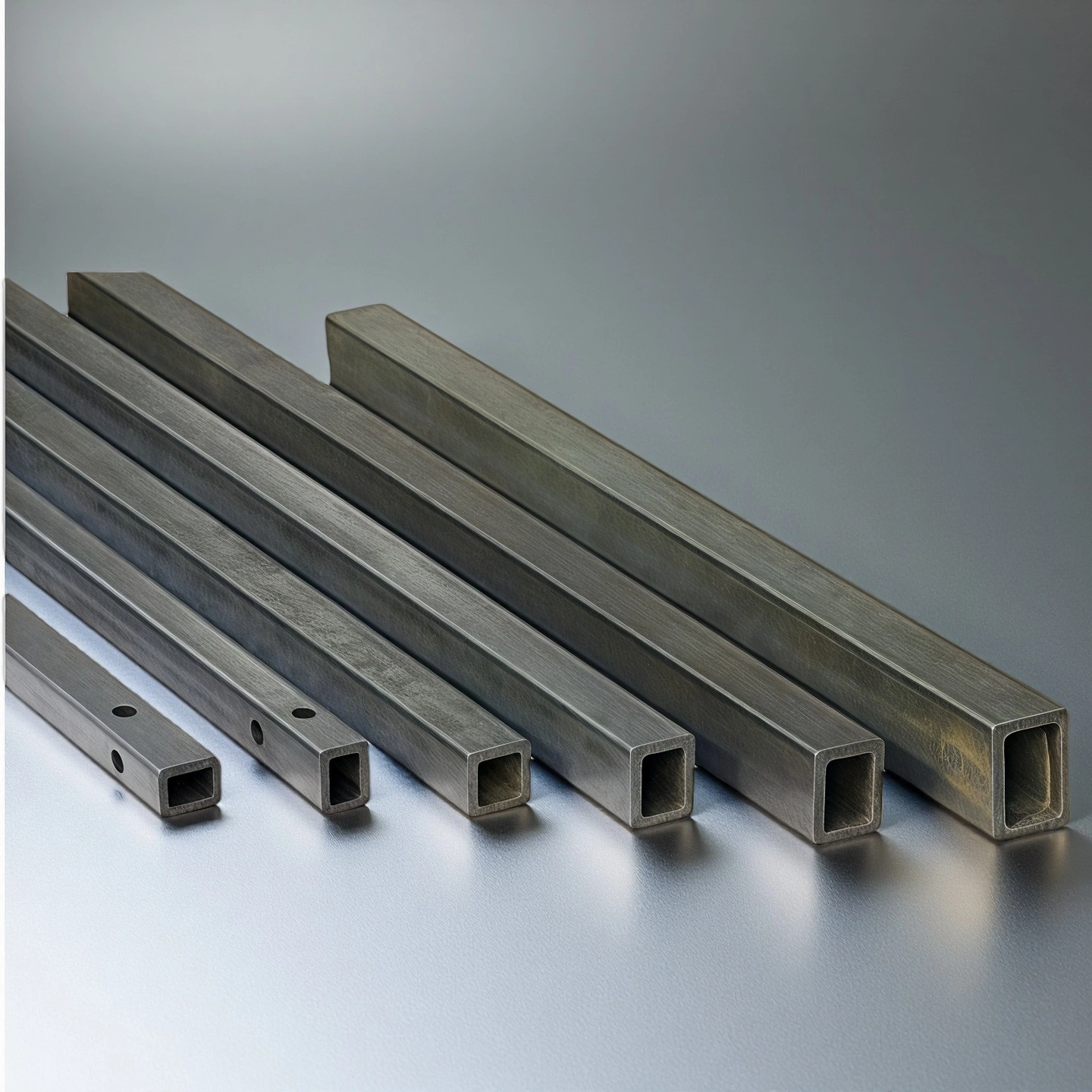

ADCERAX® Nitride Bonded Silicon Carbide Beam is a high-performance material designed for extreme high-temperature environments. Combining the strength of NBSiC Beam with excellent thermal conductivity, it offers superior resistance to oxidation and thermal shock, making it ideal for use in industrial kilns and furnaces. This beam significantly improves the efficiency of thermal processes while ensuring long-lasting durability under challenging operating conditions.

Performance Characteristics of Nitride Bonded Silicon Carbide Beam

-

The NBSiC Beam can withstand temperatures of up to 1500°C, making it ideal for use in kilns and furnaces operating at extreme conditions.

-

With a thermal conductivity range of 120-150 W/m·K at 1000°C, the NBSiC Beam ensures efficient heat distribution.

-

The NBSiC Beam has a flexural strength of ≥ 300 MPa, ensuring it can withstand heavy loads in high-stress environments.

Technical Specifications of Nitride Bonded Silicon Carbide Beam

The Nitride Bonded Silicon Carbide Beam is engineered to perform reliably in extreme high-temperature applications. Combining Silicon Carbide with Silicon Nitride, this beam offers outstanding mechanical strength, excellent thermal conductivity, and superior resistance to oxidation. Its composition makes it an ideal choice for use in industrial kilns, refractory furnaces, and heat treatment equipment, providing efficiency and durability in demanding environments.

| Property |

Specification |

| Maximum Operating Temperature |

1500°C |

| Thermal Conductivity |

120-150 W/m·K at 1000°C |

| Flexural Strength |

≥ 300 MPa |

| Density |

3.10-3.20 g/cm³ |

| Hardness (Vickers) |

≥ 2500 HV |

| Modulus of Elasticity |

≥ 400 GPa |

| Coefficient of Thermal Expansion (CTE) |

3.0 × 10⁻⁶ /°C |

| Oxidation Resistance |

High |

| Chemical Resistance |

Resistant to most acids and alkalis at high temperatures |

| Mechanical Strength |

High tensile strength |

| Impact Resistance |

High |

| Service Life |

Long-lasting |

| Resistance to Thermal Shock |

Excellent |

| Heat Distribution Efficiency |

Even |

| Environmental Resistance |

Excellent under oxidative environments |

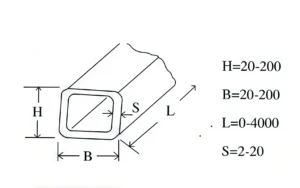

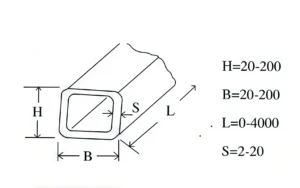

Dimensions of Nitride Bonded Silicon Carbide Beam

Packaging Method for Nitride Bonded Silicon Carbide Beam

The Nitride Bonded Silicon Carbide Beam is carefully packaged to ensure safe transportation and handling. Each beam is securely wrapped and placed in protective crates, with adequate padding to prevent any damage during transit. The packaging is designed to protect the beam from external shocks, ensuring it arrives in excellent condition for use in high-temperature applications.

Solving High-Temperature and Durability Challenges with Nitride Bonded Silicon Carbide Beam by ADCERAX®

The Nitride Bonded Silicon Carbide Beam by ADCERAX® is designed to meet the rigorous demands of high-temperature environments. With its exceptional mechanical strength, thermal conductivity, and resistance to oxidation, it addresses key challenges faced by industries like ceramics and metal smelting. Its unique properties enable efficient operation in demanding conditions, offering long-lasting performance and reliability for high-stress applications in kilns, furnaces, and other heat-intensive environments.

-

Ceramic Kiln Applications: Enhancing Efficiency in Tunnel and Shuttle Kilns

✅Key Advantages

1. High-Temperature Resistance

The NBSC Beam is capable of withstanding extreme temperatures up to 1500°C. This ensures reliable performance even in the most demanding kiln environments, allowing continuous operation without degradation.

2. Thermal Conductivity for Even Heat Distribution

The beam’s superior thermal conductivity helps distribute heat evenly across the kiln, reducing thermal stress. This consistent heat flow prevents uneven firing and enhances the quality of ceramic products, ensuring efficient kiln operation.

3. Long-Lasting Durability

Designed for long-term use, the NBSiC Beam offers high mechanical strength and resistance to thermal cycling. It significantly reduces the need for frequent replacements, leading to lower maintenance costs and minimizing downtime in ceramic kilns.

✅ ️Problem Solved

In a ceramic manufacturing facility, traditional kiln beams often suffer from frequent degradation due to the high temperatures and extended exposure to thermal cycling. A client faced high maintenance costs and production delays because their existing beams would weaken and crack after only a few months of use. With the NBSiC Beam, the client experienced a significant improvement in both kiln efficiency and durability. The new beams withstood temperatures up to 1500°C without failure, increasing production uptime by 25% and reducing maintenance costs by 40%. This led to a more reliable and efficient operation for their kiln systems.

-

Metal Smelting Industry: Maximizing Furnace Efficiency and Durability

✅Key Advantages

1. High Resistance to Molten Metals

The NBSiC Beam can withstand the extreme conditions of molten metal environments. Its resistance to molten metals ensures that it remains structurally intact, preventing premature wear and maintaining furnace efficiency.

2. Thermal Shock Resistance

With its excellent ability to withstand rapid temperature fluctuations, the beam remains intact even under thermal shock conditions. This resilience prevents cracking and extends the lifespan of the furnace components, maintaining high performance throughout its operational life.

3. Heavy Load-Bearing Strength

Designed to endure the weight of molten metals and other heavy loads, the NBSiC Beam offers high compressive strength. This makes it ideal for supporting the structural integrity of the furnace, ensuring stable and safe operation.

✅ ️Problem Solved

A metal smelting plant was facing issues with frequent furnace component replacements due to the corrosive nature of molten metals and extreme temperature variations. After switching to the NBSiC Beam, the plant saw a substantial improvement. The beam’s resistance to both molten metals and thermal shock meant that furnace downtime was reduced by 30%, and the frequency of part replacements dropped by over 50%. The overall productivity and furnace efficiency were significantly enhanced, leading to cost savings and higher output.

-

Refractory Furnaces: Enhancing Longevity and Reliability in High-Temperature Environments

✅Key Advantages

1. Chemical Resistance to Molten Metals and Slags

The NBSiC Beam is highly resistant to chemical attack from molten metals, slags, and other aggressive substances commonly found in refractory furnaces. This resistance ensures that the beam maintains its structural integrity over time, even in harsh chemical environments.

2. Thermal Cycling Durability

Refractory furnaces experience rapid temperature changes, which can weaken traditional materials. The NBSiC Beam resists thermal cycling, allowing it to perform consistently under fluctuating temperatures without breaking down.

3. Longer Service Life

Thanks to its durable composition and superior resistance to thermal shock and chemical damage, the NBSiC Beam lasts longer than other materials used in refractory furnaces. This extended service life reduces the need for frequent replacements, saving on operational costs.

✅ ️Problem Solved

In a refractory furnace used for glass production, the company faced significant wear and tear due to the aggressive nature of molten glass and frequent temperature fluctuations. The original materials would corrode and crack, resulting in costly downtimes and extended maintenance. After implementing the NBSiC Beam, the furnace saw a dramatic improvement. The beam's chemical resistance and thermal cycling durability meant that the furnace could operate at high efficiency without interruptions. As a result, the plant experienced 20% less downtime and reduced maintenance costs by 35%, improving overall furnace reliability and longevity.

User Guide for Nitride Bonded Silicon Carbide Beam by ADCERAX®

The Nitride Bonded Silicon Carbide Beam by ADCERAX® is a durable and high-performance component designed for high-temperature environments. To ensure optimal performance and longevity, it's important to follow proper handling, usage, and maintenance guidelines.

-

Handling and Storage Recommendations

1. Avoid Impact: Handle the beam carefully during transportation and installation. Severe impact can cause cracks or damage to the material.

2. Dry Environment: Store the beam in a dry location to prevent exposure to excessive humidity, which may affect its properties over time.

3. Proper Support: When not in use, ensure the beam is properly supported to avoid stress or bending, which can lead to deformation.

-

Installation and Temperature Management

1. Temperature Control: The NBSiC Beam is designed for high-temperature applications, but ensure gradual temperature changes to prevent thermal shock.

2. Proper Alignment: Ensure the beam is installed in correct alignment with kiln or furnace supports to prevent uneven pressure that could cause premature wear.

3. Monitor Temperature: Keep the temperature within recommended operating limits (up to 1500°C) to maximize the beam's lifespan and performance.

-

Maintenance and Cleaning Guidelines

1. Regular Inspections: Conduct regular inspections for signs of wear, cracks, or surface degradation, especially after extended high-temperature use.

2. Cleaning Process: Clean the beam gently with non-abrasive tools to avoid scratching or damaging its surface.

3. Avoid Chemicals: When cleaning, avoid harsh chemicals that could react with the beam's material and potentially reduce its effectiveness.

-

Safety and Operational Precautions

1. Monitor Structural Integrity: Ensure that the beam is securely fastened and properly supported during operation to maintain its stability in high-stress environments.

2. Prevent Overloading: Never exceed the beam’s load-bearing capacity to avoid deformation or failure under excessive weight.

3. Follow Manufacturer Guidelines: Always adhere to the specific guidelines provided by ADCERAX® for maintaining the beam's operational safety and efficiency.