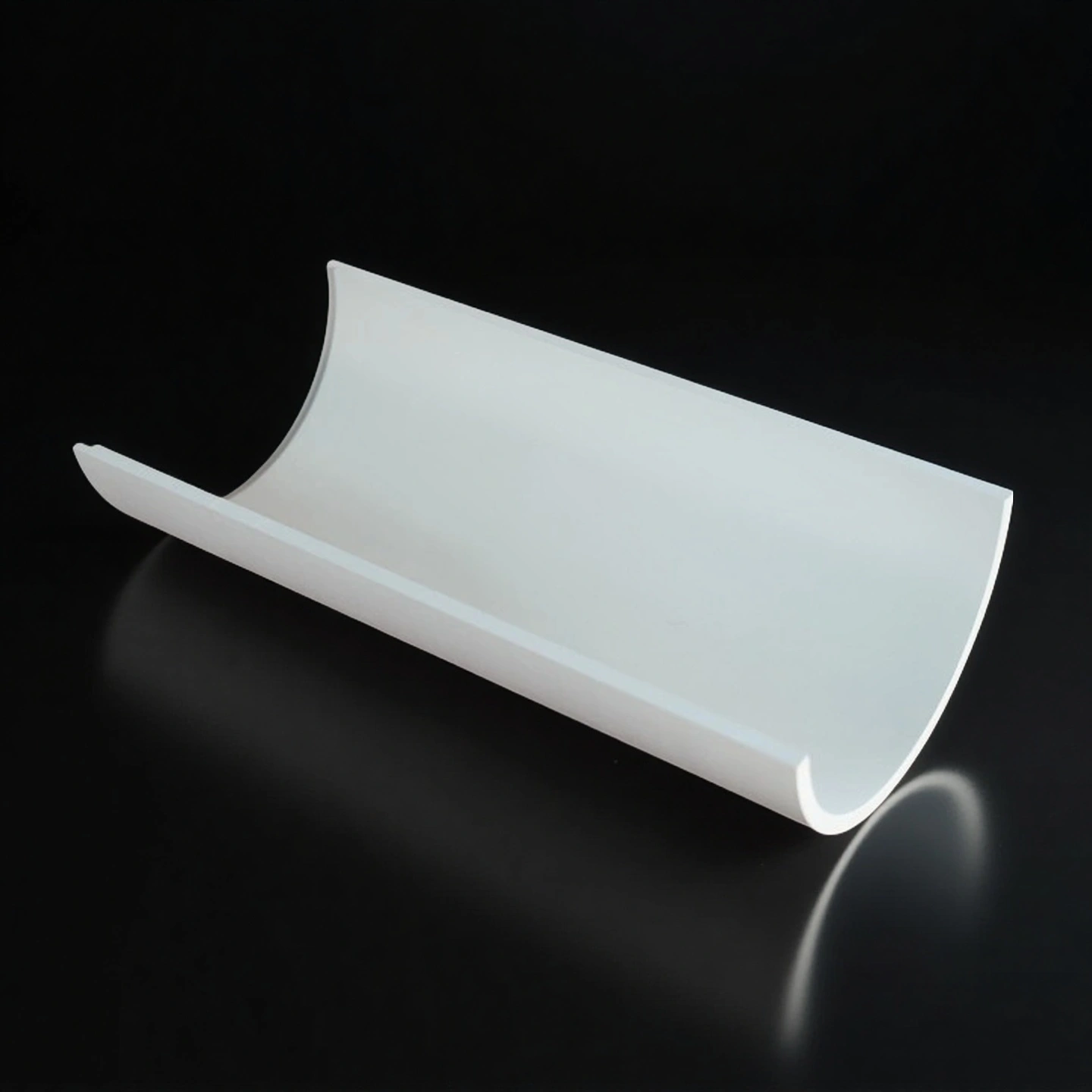

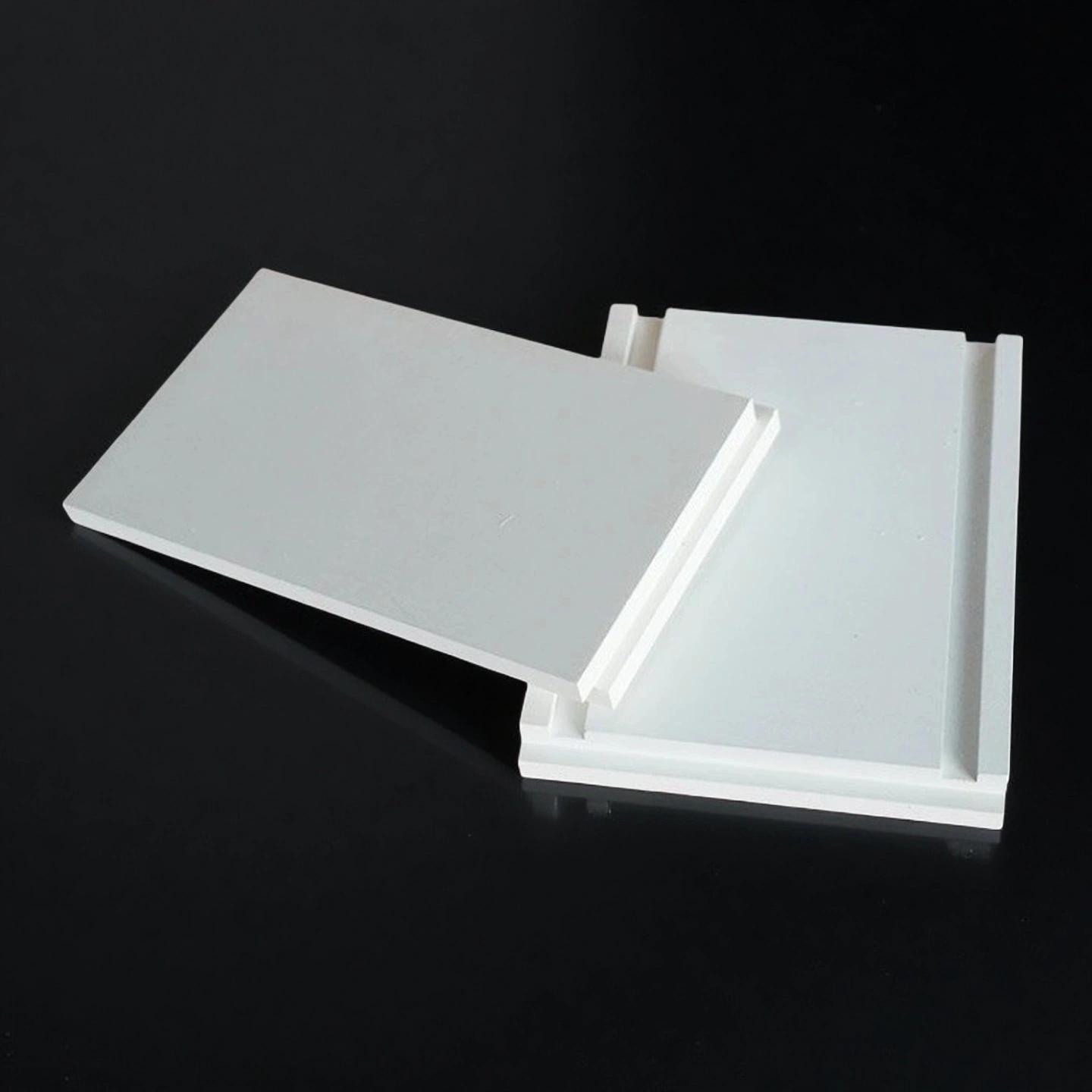

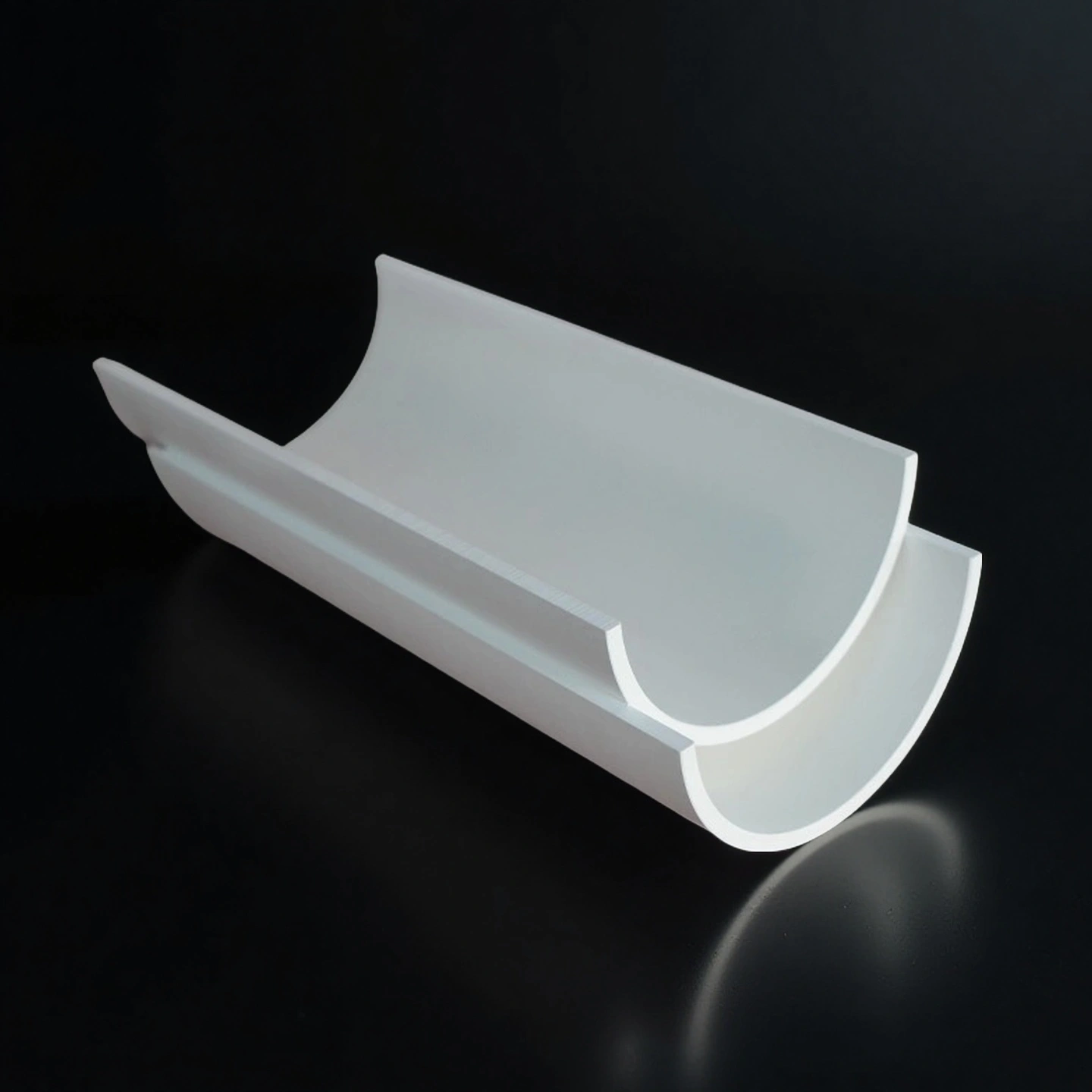

Boron Nitride Insulation Gasket is a precision-machined thermal and electrical insulating component made from hexagonal boron nitride (h-BN). It provides stable performance in high-temperature and vacuum environments, especially where non-wetting contact and chemical inertness are required.

Boron Nitride Insulation Gasket Benefits

-

Electrical Insulation & Non-Wetting Surface

High resistivity (≥10¹⁴ Ω·cm) prevents arcing and short circuits, while the low surface energy of BN avoids metal adhesion in PVD, CVD, and thermal systems. -

High-Temperature Stability

Operates up to 1800 °C in vacuum or inert atmospheres with stable structure and minimal degradation under repeated thermal cycles. -

Machinable & Customizable

Fine-grained BN allows precision machining to ±0.05 mm, supporting complex shapes such as stepped, slotted, or multi-hole gaskets. -

Thermal Shock Resistance

Withstands rapid temperature shifts (>500 °C/min) without cracking or warping, ensuring dimensional consistency in thermal processes. -

Low Thermal Expansion

Expansion coefficient close to quartz and alumina (≈2 × 10⁻⁶ /K) minimizes interfacial stress and ensures assembly stability at high temperatures.

Boron Nitride Insulation Gasket Properties

| Property | Unit | Pyrolytic Boron Nitride | Hot Pressed Boron Nitride |

| Purity | 99.99% | 99.50% | |

| Density | g/cm3 | 2.15-2.19 | 1.96-2 |

| Hardness | HV0.5 | 651 | 62 |

| Volume resistivity | Ohm*cm | 2*1014 | 1.2*1014 |

| Dielectric strength | kV/mm | 55 | 76 |

| Maximum working temperature | ℃ | 1000 (air), 2300 (vacuum) | 900 (air), 1850 (vacuum) |

| Bending strength | MPa | 173 (A direction) | 310 |

| Thermal conductivity | W/m*K | 60 (A direction) | 55 |

| Tensile strength | MPa | 112 (A direction) | 110 |

| Thermal expansion coefficient | /℃ | 6*10-7 | 1.8*10-6 |

| Compressive strength | MPa | 154 (A direction) | 120 |

BN Insulation Gasket Specifications

| Boron Nitride Insulation Gasket | ||

| Item No. | Outer Diameter(mm) | Inner Diameter(mm) |

| AT-BN-JYD001 | Customize | |

Boron Nitride Insulation Gasket Packaging

- Each gasket is individually packed in anti-static foam trays.

- Sealed plastic bags for moisture protection.