Silicon nitride roller bearing is a rolling-element bearing that uses Si₃N₄ (silicon nitride) cylindrical rollers running against steel or hybrid rings. By replacing steel rollers with ceramic rollers, the bearing gains lower mass, electrical insulation, and stable geometry at high temperature/speed, which helps reduce heat, vibration, and electrical pitting in inverter-driven or high-rpm machines.

Si₃N₄ Roller Bearing Benefits

1. High-Speed Readiness —

Low-density Si₃N₄ rollers generate 60% less centrifugal force than equivalent steel rollers at the same dn value. This allows stable operation above 1.2×10⁶ dn, with reduced contact stress and slower temperature rise under sustained high-rpm loads. The result is better thermal equilibrium, improved bearing stiffness, and consistent preload retention in long-cycle operations.

2. Insulation Under VFD Drive —

The non-conductive ceramic rolling path effectively interrupts stray currents generated by inverter-driven (VFD) systems, preventing electrical discharge machining (EDM) and grease carbonization. Tests on hybrid bearings with Si₃N₄ rollers show over 90% reduction in current erosion marks compared with standard steel rollers, extending bearing life in traction motors and precision drives.

3. Tight Geometry and Dimensional Control —

Each roller is precision ground to ≤1–3 μm roundness and length matching within ±2 μm, ensuring consistent load sharing and minimized runout. This tight tolerance control enhances system NVH (noise, vibration, harshness) performance and maintains preload accuracy in high-stiffness spindle or motor assemblies.

4. Stable Surface Finish and Friction Behaviour —

A super-finished outer diameter Ra ≤0.02 μm reduces friction scatter, helping maintain predictable torque and temperature profiles during acceleration phases. Polished surfaces also minimize lubricant shear degradation and stabilize the bearing’s thermal expansion, which is critical in continuous-duty or thermally cycled environments.

5. Clean Running for Vacuum and Precision Assemblies —

Silicon nitride’s dense, closed microstructure and smooth surface drastically lower particle emission. This supports ISO Class 5–6 cleanroom compatibility and ensures long-term reliability in turbomolecular pumps, vacuum coating chambers, and analytical instruments. The low-wettability surface reduces adhesion of contaminants, maintaining internal cleanliness and balance stability.

Silicon Nitride Rollers Bearing Properties

1. Silicon Nitride Bearing Rollers Technical Sheet

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

2. Roller Grade Tolerance (Unit: μm)

| Tolerance Grade | Ra (Surface Roughness) | Rolling Surface (max) | End Face (max) | Chamfer (max) |

|---|---|---|---|---|

| 0 | 0.1 | 0.125 | 1.25 | |

| I | 0.125 | 1.16 | 1.25 | |

| II | 0.16 | 0.25 | 2.5 | |

| III | 0.25 | 0.32 | 2.5 |

Si3N4 Roller Bearing Specifications

| Si3N4 Roller Bearing | |||

| Item NO. | Inner Diameter(mm) | Outer Diameter (mm) | Width(mm) |

| AT-SIN-ZC001 | 25 | 52 | 15 |

| AT-SIN-ZC002 | 100 | 180 | 34 |

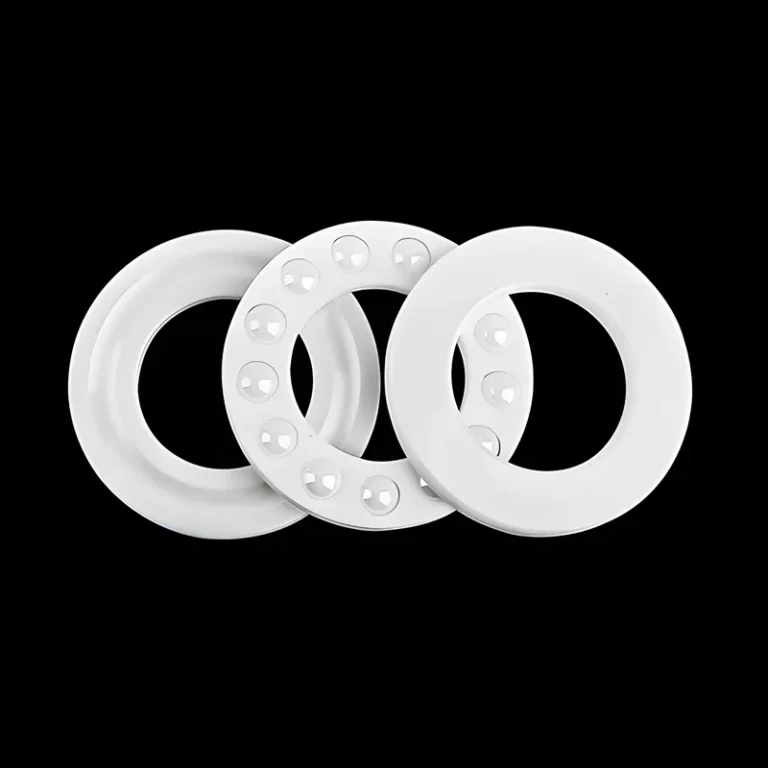

Silicon Nitride Cylindrical Roller Bearing Packaging

- Each bearing is sealed in anti-static polyethene bags

- Packaged in foam-lined rigid cartons for shock protection

![]()