Silicon Nitride Nozzle (Si₃N₄) is a precision ceramic nozzle made from silicon nitride and used to shape or meter a jet of gas, liquid, or particulate media under abrasive, hot, or thermally cycling conditions. It’s chosen when the orifice must keep its diameter and geometry stable for long runs while resisting chipping and thermal shock.

Silicon Nitride Nozzle Benefits

1. Orifice stability:

The silicon nitride nozzle maintains orifice diameter longer under abrasive streams due to its 14–16 GPa hardness and fracture toughness of 6–8 MPa·m^0.5. This combination minimizes micro-edge chipping and extends service intervals by roughly 2–3 × compared with alumina or SiC nozzles.

2. Thermal-shock tolerance:

It withstands repeated hot–cold cycles with minimal crack propagation, supported by a low thermal expansion coefficient (~3 × 10⁻⁶ /K). In casting and selective soldering lines, this prevents failure when rapid heating and air cooling occur, maintaining consistent jet alignment through thousands of cycles.

3. Consistent spray geometry:

Controlled inlet, throat, and exit transitions keep spray cone angle and flow footprint uniform across multiple stations. Dimensional stability (runout ≤ 0.03–0.05 mm) reduces re-calibration frequency, helping maintain process repeatability on automated production lines.

4. Low wettability to solder/aluminum:

The smooth, dense Si₃N₄ surface resists molten metal adhesion, reducing buildup and cleaning downtime by 40–60 %. This property keeps flow unobstructed in selective soldering and foundry cells, ensuring continuous operation and predictable spray pattern quality.

5. Lightweight handling:

With a density of approximately 3.2 g/cm³, the silicon nitride nozzle weighs 30–40 % less than comparable tungsten-carbide or stainless-steel versions. The lower mass improves manual ergonomics for operators and reduces spindle load in automated arms, extending bearing life.

Silicon Nitride Ceramic Nozzles

|

Si3N4 Type |

Gas pressure sintering Si3N4 |

Hot pressing sintering Si3N4 |

High thermal conductivity Si3N4 |

|

Density (g/cm3) |

3.2 |

3.3 |

3.25 |

|

Flexture strength (MPa) |

700 |

900 |

600~800 |

|

Young Modulus (GPa) |

300 |

300 |

300~320 |

|

Poisson's ratio |

0.25 |

0.28 |

0.25 |

|

Compressive strength (MPa) |

2500 |

3000 |

2500 |

|

Hardness (GPa) |

15 |

16 |

15 |

|

Fracture toughness (MPa*m1/2) |

5~7 |

6~8 |

6~7 |

|

Maximum working temperature (℃) |

1100 |

1300 |

1100 |

|

Thermal conductivity (W/m*K) |

20 |

25 |

80~100 |

|

Thermal expansion coefficient (/℃) |

3*10-6 |

3.1*10-6 |

3*10-6 |

|

Thermal shock resistance (ΔT ℃) |

550 |

800 |

/ |

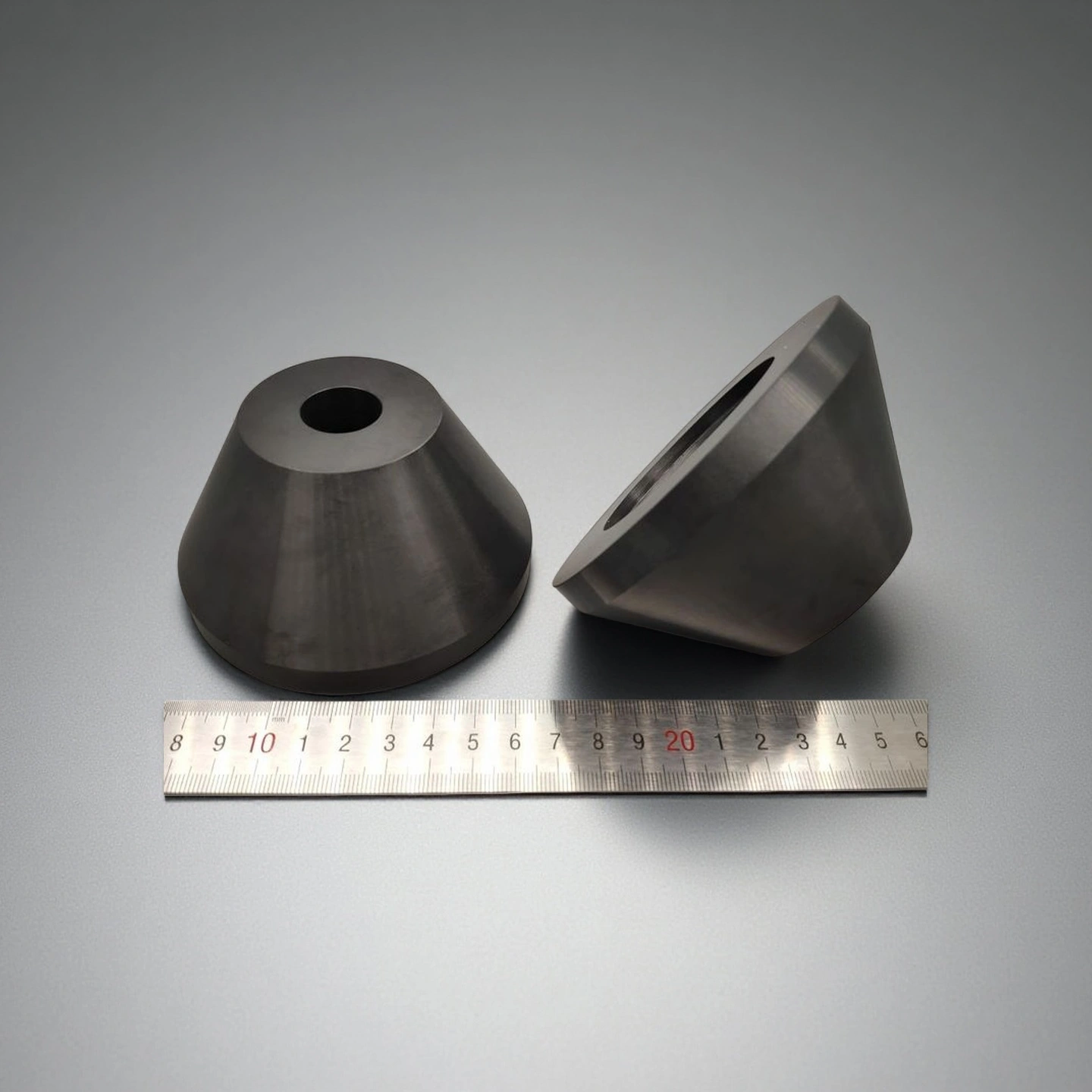

Si3N4 Nozzle Specifications

|

Silicon Nitride Nozzle |

|

Item No. |

Diameter(mm) |

Height(mm) |

|

AT-SIN-PZ1001 |

Customize |

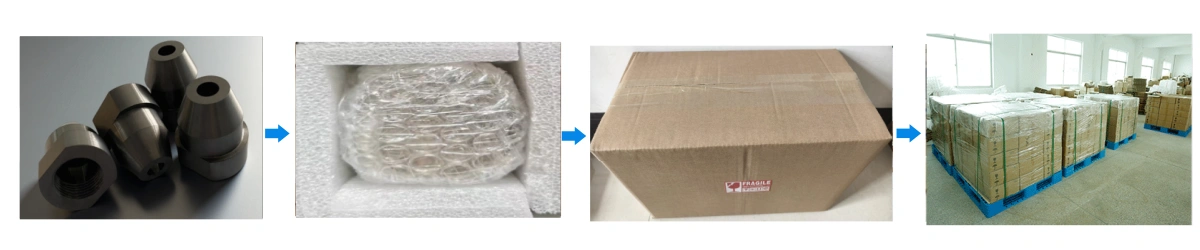

Silicon Nitride Nozzle Packaging

- foam cell tray to isolate tips; oil-free bag to keep surfaces clean.

Silicon Nitride Ceramic Nozzle Usage Instructions

Proper installation, operation, and maintenance directly affect nozzle performance and lifespan. Follow these steps to achieve consistent spray geometry, extended wear life, and safe handling during production.

-

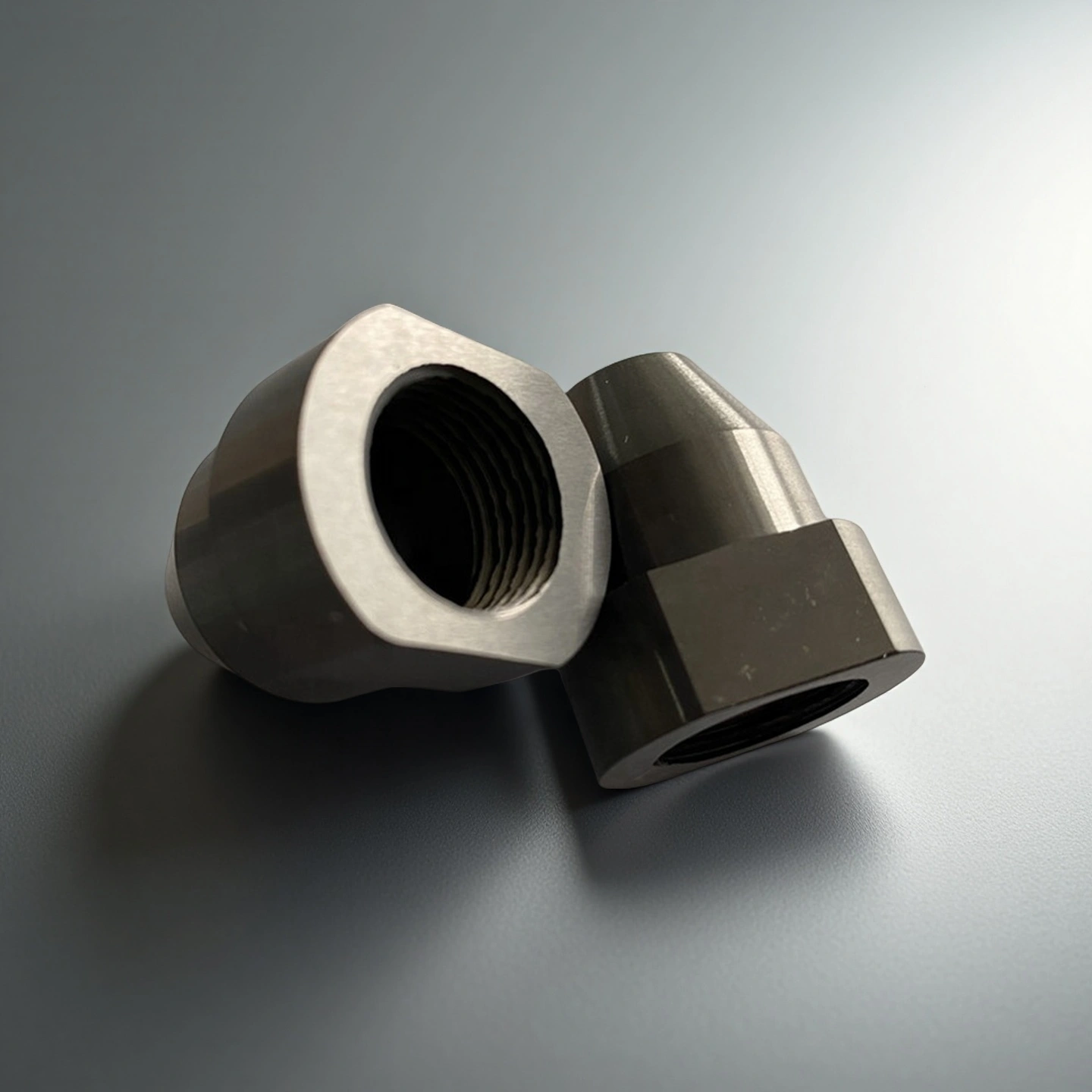

Installation

1. Seat Verification:

Confirm the correct seat type (threaded, slip-fit, or step). Apply torque within fixture specifications — typically 3–6 N·m for M8–M10 threads — and avoid wrenching directly on the ceramic body.

2. Coaxial Alignment:

Check the coaxiality between the nozzle bore and the spindle or arm axis; measure runout at the outlet face (≤0.05 mm typical). Misalignment can cause uneven spray and localized wear.

3. Inlet / ID Inspection:

Inspect the inner bore with a precision pin gauge before use. Reject nozzles if burrs, chips, or internal scratches are detected, as these defects can disturb flow velocity and reduce lifespan.

4. Gasket / Seal Fit:

Ensure that sealing rings, O-rings, or soft washers are installed evenly to avoid stress points on the ceramic seating edge.

-

Operation

1. Media & Flow Control:

Maintain proper media filtration (≤150 µm) in blasting systems; oversized grit or debris causes accelerated ID wear.

2. Temperature Stability:

For soldering or foundry applications, allow preheat cycles before operation. Avoid rapid thermal gradients exceeding 300 °C/min to prevent microcracking.

3. Equipment Settings:

In selective soldering, adjust jet height and cone width according to OEM calibration charts. In blasting, keep air pressure and stand-off distance consistent for balanced wear.

4. Physical Protection:

Avoid sudden impacts or direct contact with metallic fixtures. Although Si₃N₄ offers high toughness, its fracture mode is brittle rather than ductile.

5. Visual Monitoring:

Regularly inspect jet shape and spray angle; changes may indicate orifice wear, partial blockage, or misalignment.

-

Storage

1. Protective Arrangement:

Store nozzles individually in foam or plastic trays to prevent outlet-edge contact. Separate finished nozzles from unfinished or metallic components.

2. Environmental Control:

Keep in a dry, dust-free cabinet with <60% relative humidity. Prolonged exposure to moisture may lead to surface oxidation during long storage.

3. Transport Precautions:

Use anti-shock wrapping and corner guards during shipment. Avoid stacking cartons vertically.

-

Cleaning

1. Routine Maintenance:

Clean orifice and inlet using non-metallic rods or nylon brushes; never insert steel picks. Remove accumulated particles with low-pressure air (<0.5 bar).

2. Solder or Metal Residues:

For soldering nozzles, use isopropanol or designated flux removers after cooldown. Avoid quenching a hot nozzle in cold solvent or water to prevent thermal stress fractures.

3. Periodic Deep Cleaning:

Every 50–100 hours of use, soak in mild neutral detergent solution (<60 °C), rinse with deionized water, and air-dry completely before reinstallation.

![]()