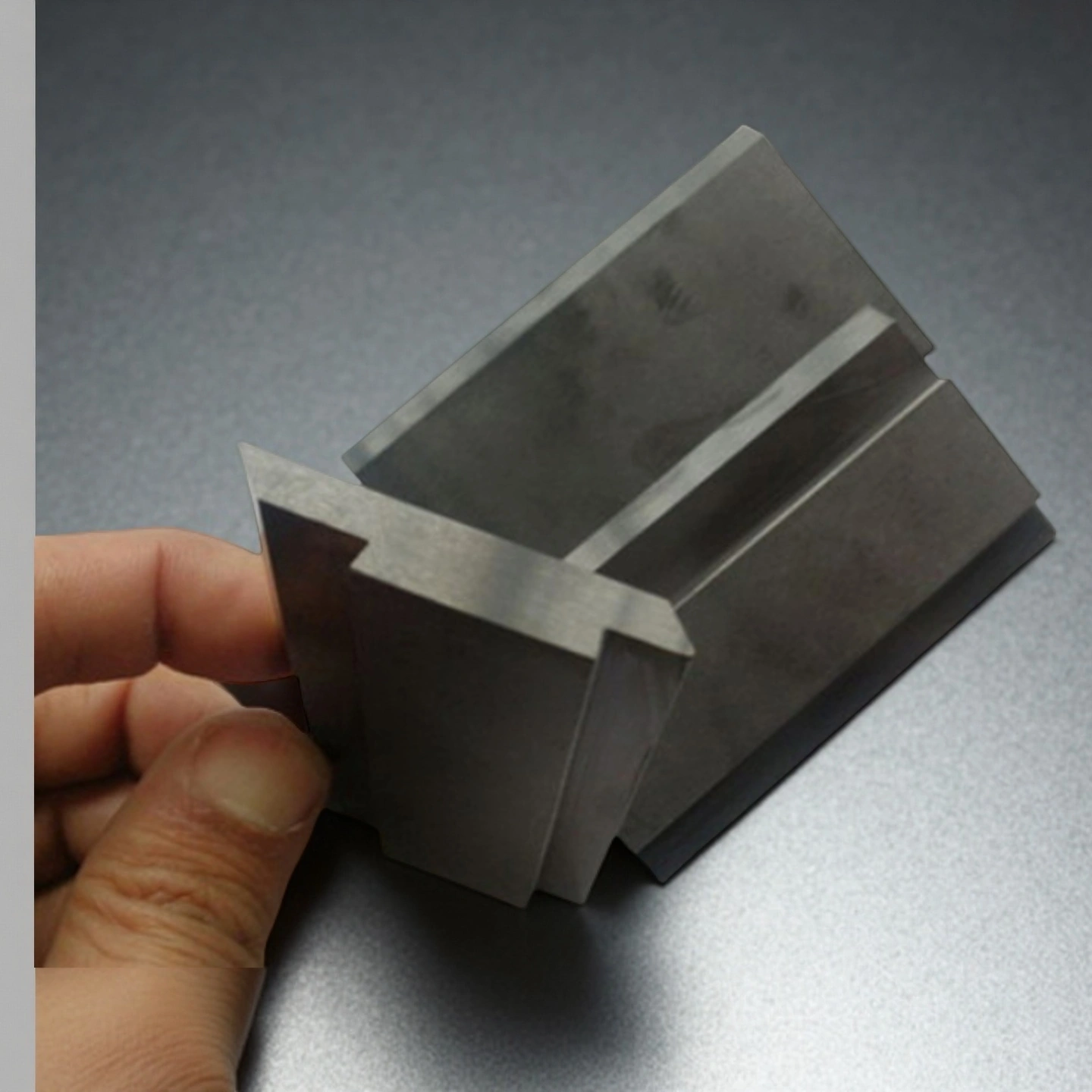

A silicon nitride dewatering element is a precision-machined Si₃N₄ ceramic plate or foil used under the forming fabric of board, paper and tissue machines—typically on forming boards, hydrofoils and vacuum or felt suction boxes—to support the fabric and control water removal from the pulp. It combines the high hardness, strength and wear resistance of silicon nitride with a smooth, low-friction surface, so it maintains drainage slots or drilled patterns accurately over long running times, reduces fabric drag and energy use, and provides stable, efficient dewatering in high-speed wet-end positions.

Silicon Nitride Dewatering Element Benefits

-

Extended wear life in high-speed wet ends

Silicon nitride combines high hardness with good fracture toughness, giving significantly longer service life than plastic covers or lower-grade ceramics on high-speed forming and vacuum positions. -

Low-friction surface for reduced drive load

A finely ground Si₃N₄ surface forms a stable water film under the forming fabric, reducing friction and related drive power consumption in vacuum boxes and foils. -

Stable drainage geometry over the full service life

High wear resistance keeps slot depth, edge profiles and drilled patterns stable, helping to keep drainage curves and formation quality consistent over months of operation. -

Resistant to chemical cleaning and white water conditions

Silicon nitride shows good resistance to process water chemistry and common cleaning agents in the forming section, limiting surface degradation and micro-pitting. -

Suitable for all machine speed ranges

The combination of high strength, thermal stability and low thermal expansion allows the same material class to be used from conventional speeds up to modern high-speed lines.

Silicon Nitride Dewatering Element Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Si3N4 Dewatering Element Specifications

| Si3N4 Dewatering Element | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-SIN-MB1001 | Customize | |

Silicon Nitride Dewatering Element Packaging

- Each silicon nitride dewatering element is individually wrapped in soft protective material to avoid surface scratches and edge chipping.

![]()